The new GEMÜ P600S multi-port valve block solution allows for a flexible combination of standardized single components. The new modular system, therefore, offers advantages regarding procurement and inventory-keeping, whilst simultaneously ensuring the achievement of highly individual actuator travel and flow paths.

In addition to multi-port valve blocks manufactured on a case-by-case basis, today modular and partly standardized block systems made of plastic or stainless steel are already in use in many sectors. Thanks to the systematic construction of the modules, complex valve assemblies can be paired in a variable way based on fewer basic bodies, meaning complex actuator travel and flow paths can be produced with different layouts of basic bodies.

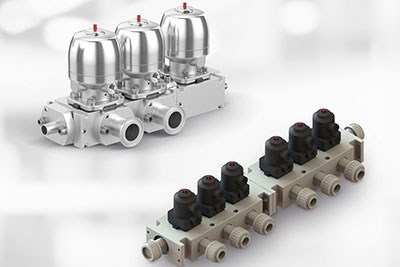

GEMÜ P600S is available in various plastics as well as stainless steel.

With the plastic series of the new GEMÜ P600S, GEMÜ provides a multi-functional solution for blending, diverting, draining, or feeding chemically corrosive media. The modular M-block diaphragm valve is available in materials PP-H and PVC and in nominal sizes DN 8 to DN 25. Spigots, threaded sockets, and union ends on the basic body can be adapted to individual requirements via the flexible connection system.

With the stainless steel series of the new GEMÜ P600S, GEMÜ provides a multi-functional solution for blending, diverting, draining, or feeding demanding media in the pharmaceutical industry, biotechnology industry, and the food industry. The modular M-block diaphragm valve is available in various stainless steel materials, and in nominal sizes, DN 20 to DN 25 – other versions are available on request. Spigots, flanges, and clamps on the basic body can be adapted to individual requirements via the flexible connection system. The interfaces for individual components have been designed based on a standardized aseptic connection.