The new Festo VZXA family of pneumatically actuated angle seat valves delivers installation, maintenance, operational, and inventory benefits thanks to a unique modular design.

When a VZXA actuator is removed for maintenance or changeover, for example, the stem, seat and seal stay inside the valve body, allowing the process system to remain pressurized. In applications containing hazardous materials, those materials reside safely within the system, saving cleaning time and lowering health and safety risks of contamination. No other angle seat valve offers these operational benefits.

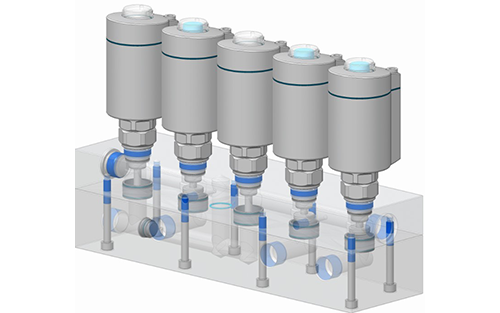

Reinstalling the actuator is simply a matter of screwing it into the valve body. The actuator does not have to be pressurized, which eliminates strain on the stem, seat, and seal and lowers the potential of damaging the valve seat. The modular design is ideal for valve manifold applications where speedy assembly, ease of maintenance, and compact size are pluses.

Modularity lends itself to valve body repair as stem, seat and seal are individual components with readily available replacement parts. The valve family’s standardized design ensures every VZXA actuator is compatible with every valve body in the family. The universal fit between actuators and valve bodies simplifies ordering and inventory management.

An online valve configurator enables the correct valve for the application standard or custom to be specified and ordered in a matter of minutes. Normally open, normally closed, and double acting actuators are available.

Line connections include threaded, sanitary clamp, and welded end. Sanitary clamps work best in washdown and clean-in-place applications where quick connect/disconnect are beneficial. Valve body materials include stainless steel and brass. Actuator bodies are stainless steel or polymer. Each VZXA actuator has an optical indicator showing valve position.