In 2022 OMAL launched the Rackon-X, a revolutionary fully wireless pneumatic actuator equipped with a data tracking unit for monitoring and storing key operating data. The result of extensive research and development, this unique product complements the emerging global trend towards integrated solutions for data tracking and predictive maintenance. Valve World spoke to Giovanni Coombs, Manager at OMAL, about how this innovation will enable the users to future-proof their facilities.

By Joanne McIntyre, Editorial Manager

The valve and actuator sector is transitioning from a mechanical industry to one focusing on mechatronics; that is, the integration of mechanical devices and electronics for control and monitoring,” begins Mr Coombs. “The Rackon-X is the first ever example of an integrated electronic device to record and transmit information on pneumatic actuators. The fact that it operates wirelessly without an external energy source makes it even more remarkable.”

The Rackon-X is a waterproof and dustproof device suitable for the most robust applications. It features an extended temperature range ideal for industrial applications and has high EMI (electromagnetic) immunity. “The electronic device matches the performance of any pneumatic actuator; wherever you’ve installed one before, you can install Rackon-X,” Mr Coombs says with a smile.

Unique electronic capabilities

The Rackon-X offers a range of new possibilities compared to other pneumatic actuators. Apart from efficiently operating a valve, it also wirelessly records and transmits key information, including the number of cycles, temperature, time taken to actuate the valve, and rotation angle. Mr Coombs explains why these information sets reveal essential data about the valve and actuator.

Number of cycles – “This largely determines the expected lifetime of the valve,” explains Mr Coombs. “For example, after 20,000 cycles of opening and closing, the seal may be worn or damaged, comprising proper sealing and closing. Valve failures result in downtime for disassembly and replacement, which is costly. An important global trend is the reduction of production line shutdowns due to hardware component failure. Putting a predictive maintenance system in place is far more efficient than waiting 4for a valve to fail. Accurately knowing the number of cycles your actuator and valve have completed is essential to predicting when the valve is approaching the end of its lifespan, enabling the user to schedule a convenient moment for replacement or repair.”

Temperature – “Unusual fluctuations in the operating temperature are important because sealing compounds are effective within a specific temperature range. The seal may fail or degrade if the temperature exceeds the normal operating limits, reducing the lifespan by preventing it from achieving its maximum achievable number of cycles. The electronic device inside the Rackon-X identifies any deviation in temperature outside normal operating range”.

Rotation angle – “Pneumatic actuators are usually installed on valves which have an open/close rotation of 90 degrees, such as ball and butterfly valves. The Rackon-X identifies if the valve has fully rotated. Any recorded deviation means there is a problem in the actuator or the valve, and a warning is transmitted to the user that the system is operating outside the set parameters. This alerts the maintenance manager to make a more detailed investigation.”

Time for opening/closing – “Air pressure enables pneumatic actuators to operate valves within a set time frame, and any deviation indicates a problem. For example, a longer opening/closing time may indicate an increase in torque, leading to increased friction and wear or even a blockage in the valve. This information is vital for an effective and efficient predictive maintenance programme.”

Long-lasting battery

A unique long-life battery is at the heart of the Rackon-X wireless system.

“OMAL utilises a high-durability battery capable of sustaining the power requirements for recording up to two million events over five years of operation,” explains Mr Coombs. “The patent-pending system allows the Rackon-X to be fully wireless, transmitting and recording information without any external power source. It is ideally suited for remote locations without the need to install extra infrastructure, power supply etc.”

“The user can always see the level of battery charge, and even if the battery were to run out completely, all information is stored in the internal memory and the cloud. To extend the long battery life even further, users should set a correct transmitting time interval for sending information to the cloud.”

Smart web interface, tamper-proof

Despite its revolutionary wireless design, installation of the Rackon-X is no different than regular pneumatic actuators. “The ease of installation extends to the X-Easy, the smart web interface OMAL provides to read and review the information collected. No sophisticated software is required to access your data; a simple but secure password-protected log-in provides direct access.”

Security is important in all electronic systems, and the Rackon-X includes a unique anti-tamper system. Mr Coombs explains: “Of course, the actuator can’t prevent someone trying to tamper with it, but it can record the event and alert the user.”

Security applications

In addition to collecting, storing and transmitting important information about the valve, the Rackon-X can also provide essential security functionality.

In addition to collecting, storing and transmitting important information about the valve, the Rackon-X can also provide essential security functionality.

“An interesting application is fuel transportation,” explains Mr Coombs. “Specialised companies move products such as gasoline and gas in tanker trucks from production sites to refuelling stations, etc. A customer approached us because fuel was being stolen from their tankers. They knew some drivers were stopping mid-route and removing fuel, but couldn’t prove it. Because tankers carry many cubic meters of cargo, it’s very difficult to determine if the load has been tampered with at the final destination. The Rackon-X offers a unique solution because it records every opening and closing of the tanker valve, so it’s simple to see if there has been an unscheduled opening of the valve en route, what time this happened, for how long, and the owner is immediately alerted. Given how many tankers are on the road worldwide every day, transporting everything from nitrogen to milk, this is a large and well-established transportation application.”

Top Italian quality

OMAL Group valves and actuators are fully designed, machined, assembled and tested at its facilities in Italy, with over 25 engineers employed in its engineering department. The Group has divided its product range into two companies: OMAL and Actuatech. The first company offers a variety of valve types (ball, butterfly, angle-seat, high-pressure), whereas Actuatech develops and manufactures pneumatic and electric actuators both for OMAL and for third parties. The company also manufactures heavy-duty actuators in various sizes, usually in very large dimensions. “We are one of the few companies specialising in both valves and actuators. As a Group, we sell over 400,000 actuators yearly,” explains Mr Coombs.

“As a specialised actuator manufacturer, Actutech is the preferred partner for many reputable valve manufacturers, for whom we re-label actuators for their complete assemblies. So while we sell directly to the market, you can also find our products under many other labels.”

“Our company has forty years of experience in developing and manufacturing actuators. Our experts have developed specific technical solutions that offer longer-life actuators compared to other companies. TUV Germany has approved all of our actuators for more than one million cycles; double the industry norm of 500,000 cycles. Our expertise includes both scotch yoke and rack and pinion pneumatic actuators.”

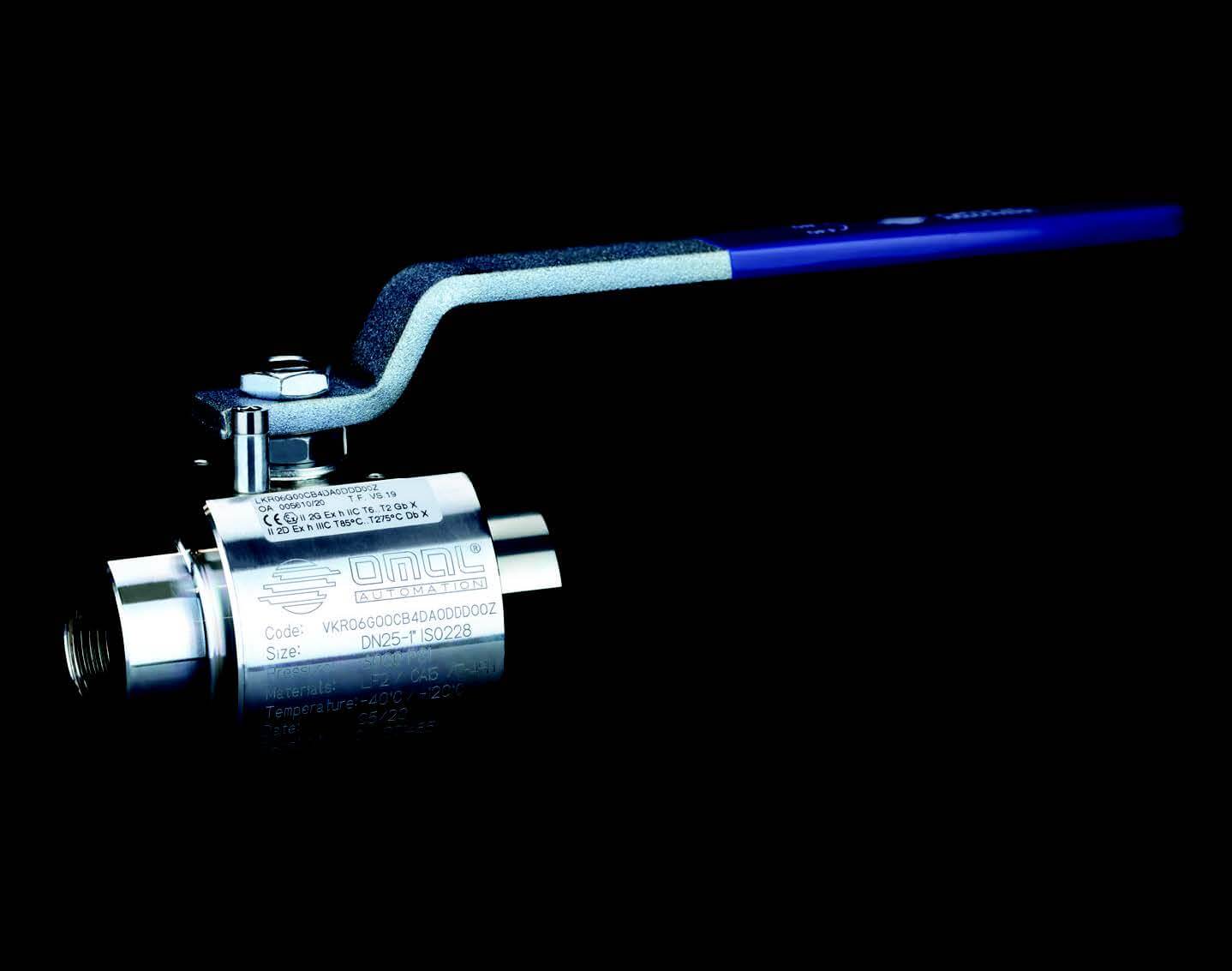

The hydrogen evolution

“As interest in the hydrogen industry has grown rapidly, we’ve received several requests from our partners in the natural gas industry to develop a range of valves and actuators for compressed hydrogen,” continues Mr Coombs. “The ball valve is our core product, so our design engineers are working on making it compatible with hydrogen processes. There are several challenges, including high pressure and the small molecule size of hydrogen which requires new sealing solutions.

The development of valves suitable for hydrogen is a major step for the industry.”

Fulfilling customer requests

With over forty years of experience in the market, OMAL’s product range includes almost any valve or actuation solution its customers require. Should the need arise, its engineering team can also adjust equipment for unique specific requirements.

“We have the ability to develop a new valve or actuator for a client, but more frequently, we adjust current products to meet their specifications,” explains Mr Coombs. “The most common request is for a new sealing compound suitable for a specific application. Our location in the north of Italy places us in an industrial hub of metal machining, valve production and rubber compounds. Within a 100 km range, we have access to hundreds of manufacturers of sealing compounds.

Our vast network of partners helps us to develop technical solutions to challenges such as broader temperature ranges, critical media, etc. At least 90% of the requests we receive are fulfilled with our standard product range, and for the rest, we work with our network of partners and our engineering team to develop a solution.”

By way of example, Mr Coombs mentions a gas operator who asked OMAL to make an actuator to fit their unique style of valve. “Major players in the process industries know we can produce unique, customised solutions for special applications, such as low torque, wider temperature ranges, etc. We have the knowledge in-house to serve all our customers, however demanding their requirements may be,” he concludes with a smile.

Società Benefit

In its effort to continually improve its standards, OMAL became a ‘Società Benefit’ in 2021. Companies that achieve this status ‘combine the goal of profit with the purpose of creating a positive impact for society and the environment and operate in a transparent, responsible and sustainable way.’

“Being a Società Benefit allows us and our employees to be part of a network of companies pioneering a change in the very concept of business, restoring value to humanity and the environment by developing markets and exhibiting those set to be the best and most profitable companies of the future”, the company states. In terms of product development, it means that OMAL strives to reduce the environmental impact of its products and increase worker safety, both through product characteristics and production methodology.

About this Featured Story

This Featured Story is an article from our Valve World Magazine December 2022 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”