The green campus of L&T Valves at Kancheepuram.

L&T Valves celebrates its diamond jubilee this year. It is marking the milestone with investments in people, products, processes and plants, powered by a revolutionary strategy for the future.

By Joanne McIntyre

To find out more, Valve World met with Chief Executive Mr Kalyanaraman, Head of Global Sales Mr Venkatesh, and Head of India Sales Mr Krishna Kumar. Mr Kalyanaraman began: “L&T Valves is the subsidiary of Larsen & Toubro, a global major engaged in EPC projects, high tech manufacturing and services. We had started small but grew consistently to become the market leader in India not only in terms of size, but also technology, quality, customer service and trust. We entered the international market three decades ago and were the first Indian manufacturer to get approvals from the global oil majors. Today our name is synonymous with reliable flow control in the industry. As we celebrate our 60th anniversary I would like to thank all the customers, partners and employees who made this journey possible. At this joyful occasion, our focus is on the next phase of growth and expansion and our transformation into a globally trusted brand.”

Five pillars of excellence

Five strategic pillars underpin the company’s future strategy, explains Mr Kalyanaraman.

“Our primary goal is enhanced value proposition to our customers. Our focus is on offering engineered solutions such as large size, high-pressure and high alloy valves, automated and digital solutions as well as aftermarket support. These offerings will reinforce our unique position in the minds of our customers as a flow-control partner rather than a supplier.”

“Secondly, people are the prime movers in our company, and this remains one of the mantras driving our business. We lay great emphasis on developing young minds for the leadership roles of tomorrow. We have recently launched a companywide organisational development programme to revitalise our culture of high performance and create an environment that is a pleasure to work in.”

In February 2023, the company successfully completed an audit for ISO 30414, the first international standard that allows an organization to get a clear view of the actual contribution of its human capital. “We may well be the first Indian engineering company that has embarked on this journey,” smiles Mr Kalyanaraman.

“We are accelerating our efforts to ensure our manufacturing operations – as well as our products – do not harm the environment. We are re-engineering our processes and products to consume lesser resources and energy. Our plants meet ISO 14001 and 45001 and already zero-discharge units. We strive to increase the green cover and last year planted a Miyawaki forest of 2500 saplings at our plant in Kancheepuram. Also, our products such as low emission valves and HIPPS contribute to a greener world by reducing harmful emissions and discharges to the atmosphere.”

“Technology is our fourth pillar. We continue to develop smart, IoT-ready solutions that enhance safety, reliability and efficiency, leveraging automation and digital technologies. We are also reimagining customer interfaces to reduce response time and enhance satisfaction. We are sure these would help us exceed the expectations of our global customer base.” “The fifth pillar is global expansion.

We currently export around 60% of our products, and the share of international business is growing.”

Global expansion

Mr Venkatesh, Head of Global Sales, outlined the company’s vision for global expansion. “Our core strategy can be summed up as ‘moving closer to the customer’ – not only in terms of sales teams but also service, manufacturing facilities and warehouses.”

“In 2022 we started a new manufacturing facility in Saudi Arabia. The plant is already approved by the major end users in the country and meets in-country value-addition requirements. Saudi plant, as well as other new facilities planned to address value addition requirements, will form supply hubs for our Middle East customers. The Middle East is a key territory for us and we have sales managers located across the region.”

“Last year a new facility and warehouse were opened in Houston, USA. Ideally located, the warehouse supports our North American distribution network with short delivery times and quick modifications and upgrades. The Houston facility will also help us make inroads into Latin America. There is significant interest in our products in Argentina, Mexico, Peru, which are virgin territories for us.”

“In Europe, a new office in Paris was opened in September 2022 and Asia-Pacific customers will soon enjoy increased service from our new sales manager located in Singapore.”

These developments bring L&T Valves closer to its customers, providing timely technical and commercial support. In addition, L&T Valves offers after-sales support starting from installation and commissioning to maintenance support and emergency response.

“We are expanding our product portfolio and application base also,” Mr Venkatesh continued. “We are a major player in oil & gas and power sectors and plan to diversify beyond the conventional energy domain. We are pursuing opportunities in allied industries leveraging our expertise in customised solutions.”

Expansion in the Indian market

Mr Krishna explains the company’s future-focused strategy for the Indian market. “Our team of engineers are spread right across the country. With over forty distributors country-wide and a large inventory, customers consider us a one-stop shop for flow control equipment.

We have an extensive product portfolio and new products are regularly being developed, with axial flow check valve being a recent addition. The passion and dedication of our design team is worth highlighting here.”

Water has emerged as a significant market for L&T Valves in India, particularly for desalination and irrigation. “We recently supplied butterfly valves measuring 132 inches,” explains Mr Krishna. “Such developments reflect the success of value co-creation with customers, which energises our product development initiatives. This cooperation extends to mission-critical projects in oil & gas and power as well as defence and aerospace.”

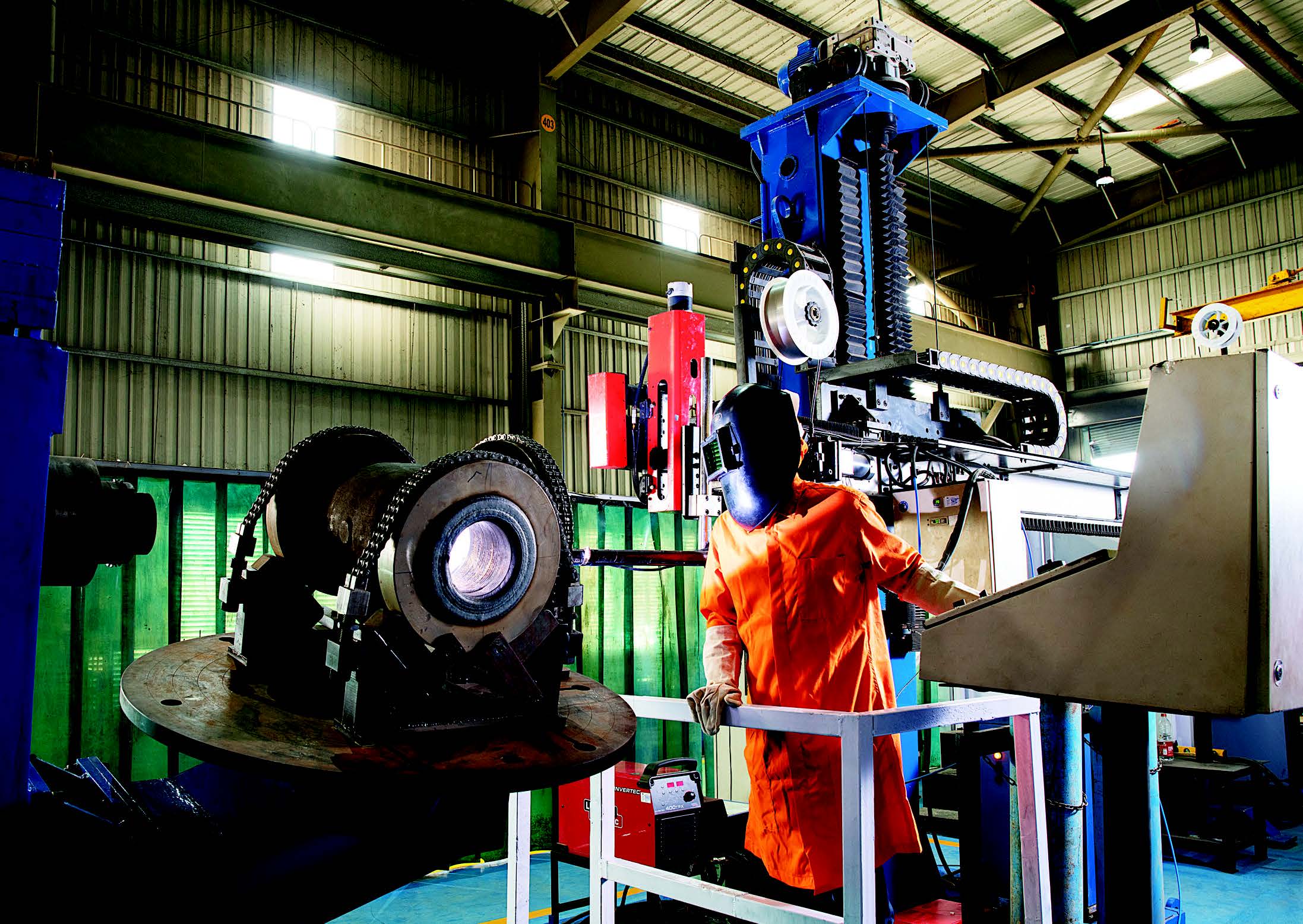

Integrated manufacturing plant

L&T Valves has two large manufacturing facilities in south India, at Kancheepuram and Coimbatore. To be future-ready, the company has taken a strategic move to integrate all manufacturing operations at the Kancheepuram plant by 1 of April 2023. The plant is located close to the national highway and is 80 km from Chennai port.

“The Kancheepuram facility is almost 30 years old with established systems and a highly experienced and skilled workforce which is comparable to the best in the world,” explains Mr Kalyanaraman. “The plant also has a host of approvals from our global customers.”

“Output from the new entity, post-debottlenecking and capacity addition, is projected to exceed the combined output from the standalone plants. The plant will future-proof our business while embodying our five pillars of excellence: value addition, people focus, environmental responsibility, technology-driven, and with a global focus. This strategic move will combine all manufacturing activities under one roof while greatly improving customer service.”

About this Featured Story

This Featured Story is an article from our Valve World Magazine, March 2023 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”