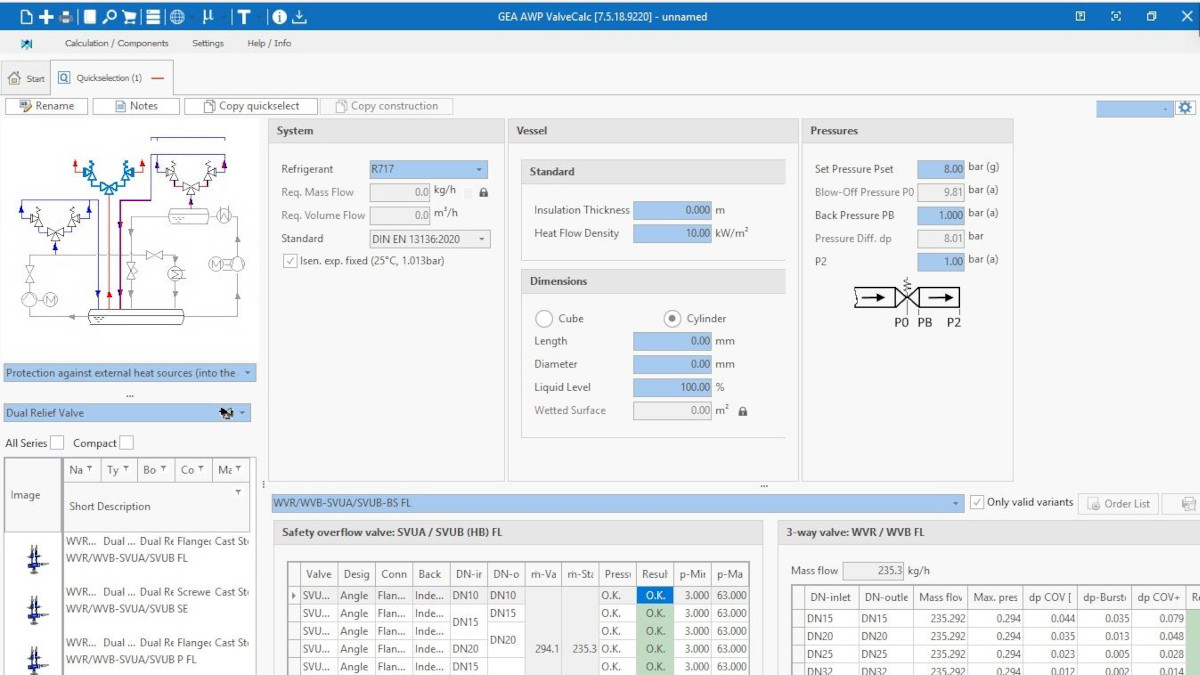

GEA AWP expands and optimizes the refrigeration design program ValveCalc with additional content and functions. The new ValveCalc 7.5 can also be used to dimension branched safety and overflow blowoff lines complete with pipes, bends, transitions, and other possible components. It provides a design environment for graphically mapping and editing a pipe network. Using drag-and-drop, essential components such as safety valves, vessels, and pipes can be inserted to build up the structure of the network. Integrated input masks are used to define additionally required data, such as refrigerant, outlet pressure, and the calculation standard to be used. The user can thus compile all sections and valves of his plant himself online with ValveCalc 7.5.

The new version ValveCalc 7.5 has been optimized visually with regard to the user interface and the view on printout sheets, and new languages such as Korean, Chinese, Polish, and Italian have been added. On the other hand, there are far-reaching content relaunches. The critical velocity is taken into account in the calculation of the branched lines calculations of safety valves as well as the different fire sections in the calculation. For the respective calculation section, new online video tutorials are available with ValveCalc 7.5.

Through the revised program, updated new product types are now also available such as WVR AL DN15-DN100, SFCS, and FT in larger dimensions. In addition, there is the possibility to calculate with own fittings and components. Thus, there is an update to the latest standard for safety valve calculation, EN13136.