Wear in valves is surely an important concern for plant owners and operators. Eroded valve internals can have a long-term effect on the functioning and profitability of process facilities. Materials such as ceramic reinforced metals can be a good solution to increase component lifetimes in industries such as oil and gas, says Valmet’s Mr Jussi Hellman.

By David Sear, Valve World

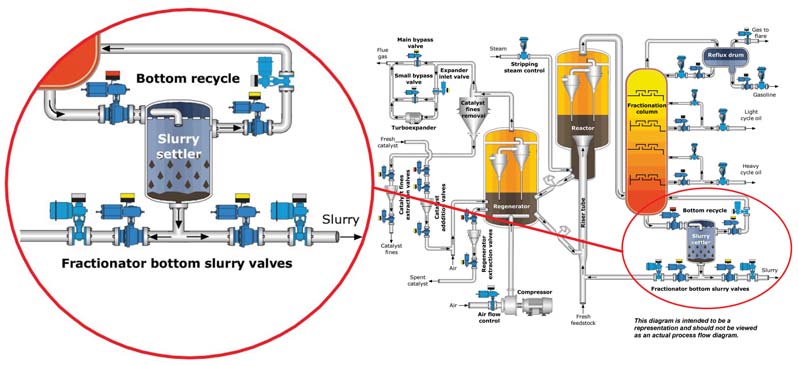

Mr Hellman is a man with a mission. His goal is to help people like refinery owners to boost plant availability by increasing the lifetime of valve components. He does this be deploying Valmet’s deep knowledge of applying a whole range of materials in severe applications. Recently, for example, he spoke to this magazine about how to manage valve wear in fluid catalytic cracking (FCC) slurry oil service (see Figure 1).

“FCC units are used in a refinery to convert heavy feedstock into lighter, more valuable products. Such units are especially valuable in refineries trying to maximize gasoline production over residual fuel oil. However, the catalysts required in this conversion process can cause problems as they have a tendency to accumulate in the bottom slurry, despite the use of settling tanks and/or filters. Such catalysts are erosive, causing challenges for items such as valves, pumps and piping,” commences Mr Hellman.

Mr Hellman therefore works with refineries to find the optimum materials solution. “Complete elimination of wear is not always a realistic objective. Therefore, what happens when a worn valve is identified for replacement depends on the operating strategy of the plant owners as they look to increase availability targets. I therefore help them to assess tolerable wear rates, taking into consideration factors such as the expected future lifetime of the system, the cost of system repair or replacement, the costs of future interruptions in plant uptimes, the likelihood of valve jamming, etc.”

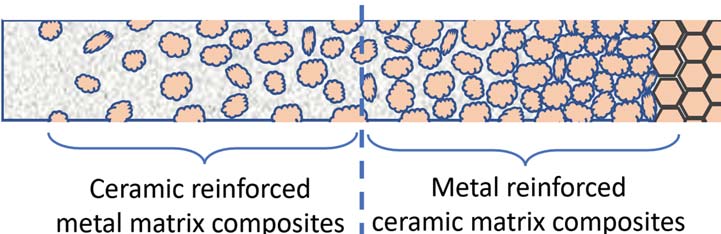

Materials options that Mr Hellman can bring to the table include thermal spray coating, weld overlays, ceramic reinforced metal matrix composites (MMC), metal reinforced ceramic matrix composites (CMC) and ceramics – see Table 1 and Figure 2. Each material has its own list of advantages and disadvantages, he notes. These include the wear resistance but also other technical issues such as bond strength, robustness, shock resistance, uniformity, crack sensitivity, use as inserts and/or closing members, etc. “Of the two composite forms it is the MMC type that has particular merit for valves destined for severe applications such as slurry oil. That’s because MMC items are mechanically very reliable, which is a key priority for the valve sector,” comments Mr Hellman.

Life cycle cost analysis

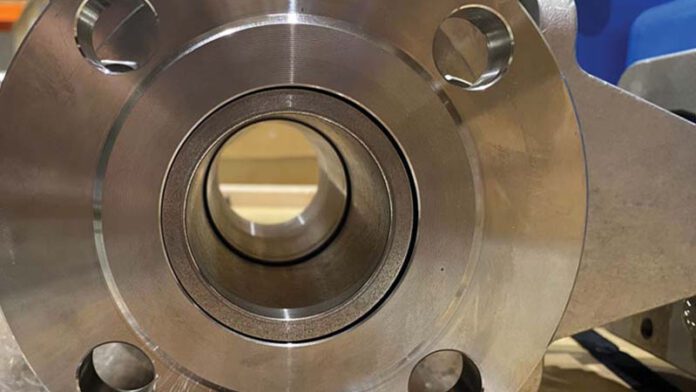

Ceramic reinforced composite materials may sound new to many in the valve industry but the materials themselves were invented in the 1920s. Moreover, these materials have since proven their effectiveness in a range of applications. “Valmet’s history of deploying MMC materials into products dates back to the 1990s, with parts destined for use in minerals processing as well as the oil and gas sector. These early success stories lead to the use of MMC materials in other Valmet products such as valves from around 2010 onwards,” states Mr Hellman.

“Having a track record was a major help when talking to the first potential valve customers in conservative industries such as oil and gas. We were able to demonstrate that MMC materials are both effective and safe. And over the years we have amassed a vast number of references and images which clearly show how well MMC materials perform over time.”

Interestingly, companies wishing to use such advanced materials in their products cannot simply go out and buy MMC ‘off the shelf’ as it were. Instead, manufacturers purchase the raw materials from which they create the ceramic-metal composites themselves. Fortunately, from an end-user perspective this step is not a hurdle.

Be that as it may, materials such as MMC will inevitably cost more than less exotic options. However, Mr Hellman stresses that they can in fact quickly work out to be less expensive for purchasers. “Ceramic reinforced materials are by no means cheap so the initial investment will likely be higher than standard options. However, when applied in highly engineered products, ceramic composites can be incredibly cost effective. By limiting valve wear, advanced materials can significantly reduce spending on both planned and unplanned downtimes, bringing significant savings.”

Mr Hellman therefore sees great potential for the use of ceramic reinforced composites in the wider oil and gas industries as well as other sectors such as mining and metals. “If you have valve challenges caused by erosive or corrosive media then maybe it is time to talk to us about ceramics and composite materials. And installing a long-lasting valve wont just increase your process availability, it will also help promote energy efficiency. That is an issue we are surely all interested in and is yet another reason why I derive so much satisfaction from being able to bring advanced material solutions to the market.”