OHL Gutermuth has recently overseen the production of specialized valves tailored for a pioneering research initiative, capable of withstanding extreme temperatures reaching up to +2000°C. These hot gas valves constitute a crucial component required by the Chinese Institute of Thermophysics for their aircraft engine testing apparatus.

Building upon a longstanding partnership with a Chinese counterpart, OHL Gutermuth has been entrusted with the fabrication of two unique hot gas valves for the latest research venture. The professors leading the project have placed their confidence in OHL Gutermuth’s expertise, a testament to the company’s reputation for excellence in industrial valve manufacturing.

The journey from conceptualization to delivery spanned approximately 1.5 years, reflecting OHL Gutermuth’s unwavering commitment to stringent quality standards in selecting production partners. Headquartered in Altenstadt, the company has earned global recognition for its provision of high-quality industrial valves across diverse markets, spanning from North and South America to Europe and India.

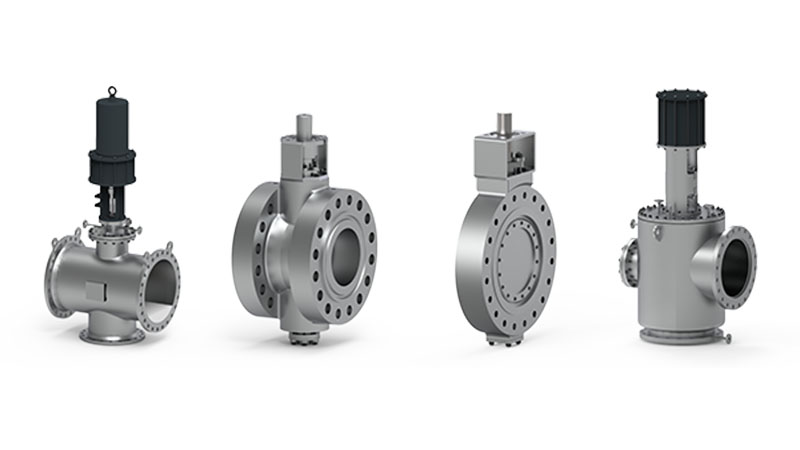

For this particular endeavor, OHL Gutermuth has collaborated with a renowned manufacturer for the first time, underscoring a successful partnership poised to facilitate future joint ventures. These specially engineered hot gas valves, with a nominal width of DN 280, have been meticulously crafted to endure gas pressures of up to 40 bar, temperatures soaring to 2000°C, and gas flow rates of up to 70 kg/s.

Drawing upon proven design principles, the hot gas valves adapted for the thermophysical project are already in use across Europe for turbine testing, underscoring their reliability and efficiency. As OHL Gutermuth continues to push the boundaries of industrial valve innovation, this collaboration not only serves as a milestone in technological advancement but also lays the groundwork for future collaborative endeavors.