Kiwa from the Netherlands, specializes in testing and certification services in a wide variety of industries. Valve World spoke with Leendert van der Marel, Director Sales & Marketing Division Products & Installations, Sander Lueb, Technical Consultant Gas, and Harald Ophoff, Account Manager, to discover more about their all-encompassing approach to implementing standards for hydrogen valves.

By Valve World

With its headquarters based in the Netherlands, Kiwa is a renowned specialist in testing, inspection, and certification (TIC). Their certification, inspection, testing, training, and consultancy services help their customers to make sure their products, services, processes, (management) systems and employees are all up to standard. Kiwa is active in various market segments, such as construction and energy supply, drinking water, healthcare, food, and feed & farming. Their main areas of expertise include management systems, corporate social responsibility, and lab testing. They serve clients in manufacturing and process industries, (business) services, public and private utilities, governments, and international institutions.

Founded in 1948, Kiwa boasts 75 years of experience in the field. They employ over 10,000 people in over 40 countries in Europe, Asia, the Americas, and Oceania. It is a member of the NVCi (the Dutch Association of Certification services).

Standards for hydrogen valves

Within the industry, a broad variety of standards and regulations exist for valves, as they come in all sorts of materials and serve all sorts of purposes. Hydrogen has become a hot topic, which is why it’s important to make sure valves are suited for this medium and perform well within the required parameters. “In the recent past, Kiwa has conducted investigations on the differences between natural gas and hydrogen with regards to leakages, and Sander has performed tests to quantify the differences in leakages,” Harald Ophoff explains. In Kiwa’s whitepaper “Technical considerations when testing hydrogen valves with air,” Consultant Materials Ernst van der Stok discusses the results, and how to take these into account when working with the new standards.

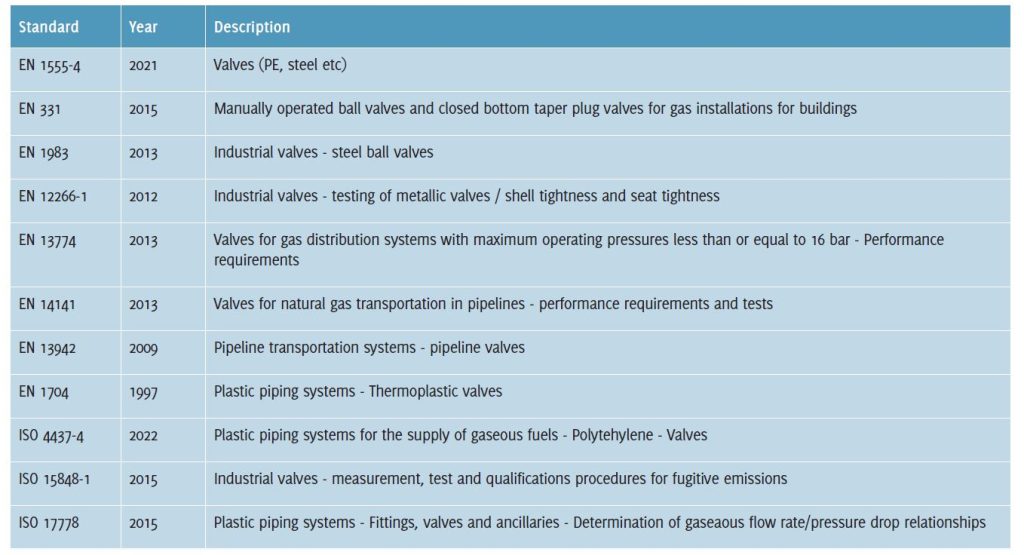

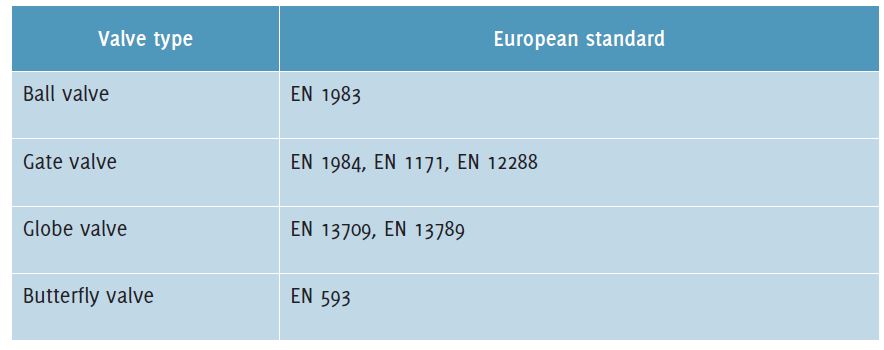

Different standards exist for different types of valves, such as lower-pressure valves, high-pressure valves, industrial valves, and valves in transportation or distribution systems. These standards are listed in Table 1. “These standards are all relevant when it comes to natural gas, so Kiwa had to figure out how to interpretate them to make them suitable for hydrogen,” Sander Lueb notes. “The AR214 (Approval Requirement by Kiwa) is the existing hydrogen standard used as a basis, and an investigation was conducted on each type of valve to see what additional testing is needed to prove that the valve is suitable for hydrogen,” explains Leendert van der Marel. “It takes out a lot of confusion. There is no need to take all these different standards into consideration, but you can refer to one: AR214. Most valves already comply with it if they’re used for gas applications.”

“This is a Kiwa standard,” Sander clarifies. “The Dutch grid companies strongly rely on – and support Kiwa – Gastec QA certified valves. Gastec QA is the certification mark, issued by Kiwa is valves comply with all the gas-related certification requirements.”

“A Kiwa standard could also be used as a basis for an international standard,” Leendert says. “Some countries are already in the process of evaluating whether they will be implementing the AR214 standard for hydrogen applications.” Kiwa is one of the first to put forward a standard for valves for hydrogen applications, acknowledging the lack of existing regulations in this rapidly evolving sector. Amongst others, there lies the strength of the Gastec QA approval.

Testing & certification

A critical aspect of Kiwa’s certification process revolves around understanding hydrogen’s unique properties, particularly its lower density and viscosity compared to natural gas. This results in significant differences in leakage rates through valves, necessitating rigorous testing and certification to ensure safety and functionality. Theoretically a leakage rate will increase in a range between 1.3 (purely laminar flow) to 3.0 (turbulent flow). In practice this value depends on leak opening and pressure.

Material compatibility with hydrogen is a primary criterion for valve suitability. Kiwa’s certification ensures that the materials used in valves are not only durable but also resistant to any potential hydrogen chemical interaction. The certification process places significant emphasis on leakage standards. Acceptance criteria vary, with some standards demanding zero leakage, while others set specific maximum values.

With approximately 50-60 clients already certified by Kiwa, the impact of their certification extends globally. Their rigorous standards and testing methodologies ensure that valves used in hydrogen applications meet the highest safety and quality standards, providing confidence to manufacturers, distributors, and end-users.

Kiwa’s approach to certification is meticulous. It begins with compliance to existing European and international standards for natural gas valves, followed by additional requirements specific to hydrogen. This involves a comprehensive process including factory inspections, testing of sample valves, and ongoing production surveillance. The certification is not a one-time event but involves biannual factory inspections and annual sample testing to ensure continuous compliance. When the scope of European standards are extended for the use with hydrogen these new standards will be applied by Kiwa. The updates of European standards may take a few years.

Conclusion

Kiwa stands out in the certification realm by offering a unique blend of services – testing, inspection, and certification – all under one roof. This integrated approach, coupled with their involvement in various industries and participation in international standard committees, allows Kiwa to offer a holistic and highly competent certification process. Additionally, Kiwa extends its expertise in consultancy, aiding distribution system operators (DSOs) in assessing and adapting their existing infrastructure and products (including valves) for hydrogen compatibility.

About this Featured Story

This Featured Story is an article from our Valve World Magazine, February 2024 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”