From January 2026, the technology group Rheinmetall will be manufacturing exhaust gas recirculation valves (EGR valves) for a renowned car manufacturer for a period of six years until December 2031. The order was booked in June of this year and amounts to a low three-digit million euro sum. By winning this order, the Group will be able to continue to utilise its production capacity until 2031. The supply of spare parts has been agreed upon for a further 15 years after the completion of valve production.

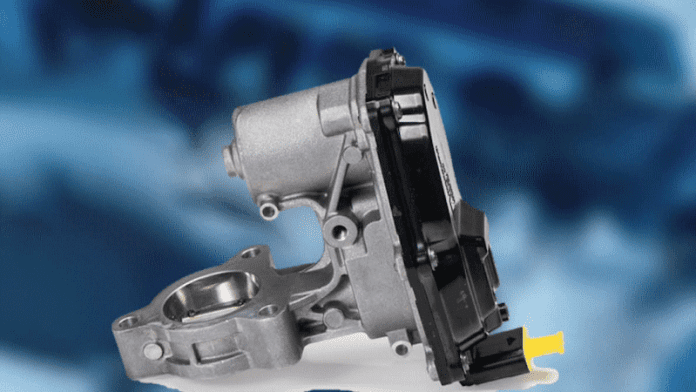

Rheinmetall is supplying the customer as a tier 1 supplier. For the order, the current compact model of the EGR valve will be customised by Rheinmetall in the area of the connections. The valves will be installed in a vehicle in the manufacturer’s commercial vehicle class. The cost-effective, fail-safe design and long service life of the component, which can also withstand high thermal and mechanical loads, are particularly important here.

The recirculation of exhaust gases reduces pollutants in both petrol and diesel engines. For this purpose, exhaust gases are extracted behind the cylinders, channelled through the EGR valve, and mixed back into the intake air. In this way, less oxygen enters the cylinders, which reduces the combustion temperature and the amount of nitrogen oxide can be reduced by up to 70% – because the temperature level has a significant influence on the emission of harmful nitrogen oxides.