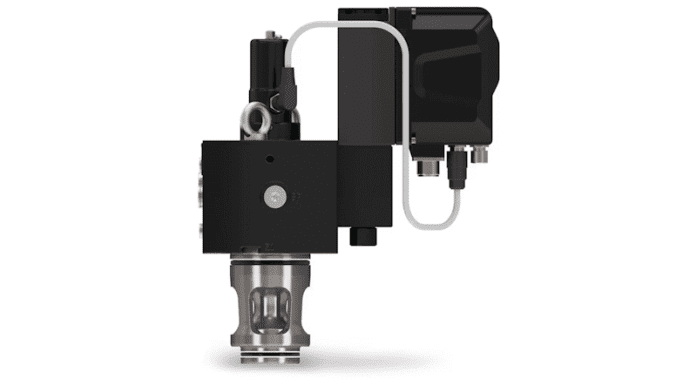

Parker Hannifin is introducing the enhanced version of the proportional cartridge throttle valve series, TFP, along with its DFplus® generation IV pilot valve. The new pilot valve further reduces the step response times by up to 30%, making the TFP the fastest valve in its class. Together with the innovative design of the sleeve and spool that allows for previously unattainable volume flow and pressure drop values, the TFP series enables shorter cycle times, more stable processes, and minimized scrap rates.

The new dual-core processor in the DFplus generation IV pilot valves enables them to run at maximum performance while simultaneously communicating with the PLC, and the retention of the analogue command signal combined with the valve’s standard IO-Link connection for communication is unique. This advancement allows for a further shortening of the acceleration phase of the shot cylinder in a die casting machine, thereby enabling the production of structured and large-area die cast parts with high and repeatable quality.

An integrated near-field communication (NFC) chip allows users to obtain all status information in the field or in service situations with a mobile device like a mobile phone or a tablet – even when the valve is not actively powered. The “Parker Device Connect” app, available for free, enables communication between the valve and the mobile device. Additionally, a 360° LED at the top of the electronics box ensures that the basic status data is immediately visible in the application by different colors or flashing frequencies.