Since 1876, Bonney Forge has pledged to manufacture quality products that exceed customers’ expectations for all-round performance. This mission still applies today across the company’s current product scope, which includes forged valves, cast valves and an exceptional range of fittings. Speaking to Valve World, Paul Heald and Antonio Sonzogni confirm Bonney Forge can serve a wide range of customer needs, including commodity valves for MRO activities, engineered valves for severe service applications and complex packages involving multiple (actuated) valve types for world-scale projects.

By KCI Editorial

Asked about Bonney Forge’s strengths, Mr. Heald (Vice-President of Product Engineering, Specialties and China Operations at WFI Bonney Forge in Texas) immediately focused on the company’s fully integrated manufacturing and forging activities. “While many companies have long outsourced their forging requirements, we have expressly chosen to continue running forge operations at both of our US facilities as well as in Italy,” says Mr. Heald. “Having our own forging means we can produce the exact items we need, to our quality standards and to our timeline. We truly are a fully integrated manufacturer. Customers who purchase a Bonney Forge valve are buying a product that has been designed, forged, machined, assembled and tested in-house.”

Mr. Sonzogni (Managing Director of Bonney Forge Europe (B.F.E.) in Bergamo, Italy) echoes his colleague’s assertion regarding the added value of the forging operations. “Today, B.F.E. is almost unique in Europe as a manufacturer with in-house forging. Benefits include the fact that we have absolute control over quality, as we can test both raw materials and finished forgings at will using a wide range of non-destructive tests. For example, dye penetration and ultrasonic examination.”

The same attention to detail and quality is present at Bonney Forge’s China operations where cast valves are produced. Castings continuously undergo sample testing in accordance with ASME B16.34 Special Class NDE requirements. Additional third-party sample testing is performed when finished cast valves arrive at Bonney Forge. “Providing a product that meets and exceeds industry standards is simply the Bonney Forge way,” states Mr. Heald.

Diverse customer base

Forge can assemble large valve packages for new-build projects, be that a refinery, offshore platform, pharmaceuticals plant, LNG trains, etc. Customers with MRO requirements are promptly served via the company’s extensive distribution network. Comments Mr. Heald: “When working on projects, EPCs and end users often rely on Bonney Forge for a multitude of forged, cast, commodity and engineered valves. Our fittings may also be specified, although they are often procured via a separate order.” Mr. Sonzogni notes the importance of respecting the specific requirements of each customer. “Some clients may be investing in new-builds while others are focusing on MRO activities. Buyers may need large quantities of standard valves or perhaps one-off specialty ball valves. We take the time to review the application, the expectations of all parties involved and of course the project timeline, so that we can give each client the valves and service they need.”

And, although the company does not produce actuators, Bonney Forge can readily fulfill requirements for automated packages. Thanks to in-house expertise, actuators can be procured, fitted and tested, with Bonney Forge taking responsibility for the complete unit.

Fittings and Olets®

In addition to valves, the Bonney Forge portfolio includes an exceptionally wide range of forged fittings, all designed, manufactured and tested in the US. These include elbows, tees, crosses, reducers, caps, unions, etc., available in numerous materials, connection types and pressure classes, with sizes up to 4 NPS and higher. Bonney Forge also produces high quality branch connections that enable fast and effective solutions on both new and existing piping and pipeline systems. Over the years, different connection categories have been innovated, such as the Weldolet®, Sockolet®, Thredolet®, etc.

Says Mr Heald: “Adding a branch line to a pipe is very straightforward when using our special connections.” Naturally, Bonney Forge’s branch connections meet all applicable codes and have been designed to ensure that a pipeline is not compromised. On that note, Mr. Heald specifically mentions the Sweepolet®, which is a contoured insert, integrally reinforced, installed by butt-weld branch connection with a low stress intensification factor for long fatigue life.

Mr. Heald: “When designing the Sweepolet®, we listened to concerns from the market about issues such as reinforcement, stresses and different types of vibration. What sets this branch connection apart is that it is welded into – and not just onto – the pipe, helping to absorb any acoustic energy and minimising cyclical fatigue.

This makes the Sweepolet® a connection of choice for the LNG industry, where we provide connections in relevant steel alloys.” The Sweepolet® may look unassuming, but an immense attention to detail goes into each and every product that Bonney Forge manufactures. “Significant work is required to analyse each specific piping configuration and to take the possible effects of different types of vibration into account,” says Mr. Heald. “So like all of our products, the Sweepolet® benefits from our upfront engineering capabilities as well as our proven, fully integrated manufacturing facilities and after-sales services.”

Industries served

In terms of valve sales, Bonney Forge has a long-established presence in the oil and gas industries, refineries, chemical facilities, power generation, petrochemical plants, etc. Thanks to its huge installed valve base, the company has acquired extensive knowledge of real-world valve performance. Having served the LNG sector for many decades, Bonney Forge can draw on a wealth of experience when advising clients on optimum valve materials and designs that will perform well at cryogenic temperatures. Here, too, Mr. Sonzogni emphasises the importance of robust quality control procedures. “We have been manufacturing stainless steel valves for low temperature and cryogenic service such as in liquefaction, transport and regasification systems for years. Given the critical function of valves in this sector, we naturally run a whole battery of tests, including checks on raw materials, non-destructive examination of forged components, testing of the final valve utilising our in-house cryogenic test bunker.”

Keeping close to customers and prospective clients is critical, continues Mr. Sonzogni. “We pay close attention to the demands coming from the market, consistently fine-tuning our manufacturing processes to improve quality, reduce costs and increase flexibility. Right now, I can point to interesting markets in North Africa for forged valves, and we are also supplying to green energy areas such as hydrogen and wind farms.”

“Today we are working to be able to offer specific options to meet different industry requirements like new materials, sizes, pressure ratings or special configurations,” says Mr. Sonzogni. “We also monitor new industry regulations and standards to ensure that our valves meet all necessary safety, environmental and performance requirements, and to provide technical support and after-sale service.”

Fast-track

Bonney Forge enjoys a solid reputation for its exceptional service level. It goes without saying that ordered valves, fittings and connections are delivered on-time, with the correct specifications, in appropriate packing material and with all required documentation. Moreover, Bonney Forge understands the need for flexibility in the supply chain. Mr. Sonzogni explains: “At B.F.E., delivery times for valve packages are in line with the industry norm which can be anything up to thirty weeks depending on the exact types and numbers ordered. EPC contractors know that and plan well in advance, enabling us to deliver valves to the project construction site in good time. But invariably someone somewhere along the line forgets to order a specific valve, or perhaps a change in the specifications means additional valves are needed.

Whatever the cause, project delays due to missing components can have serious consequences. That’s why B.F.E. offers a special Fast Track service, whereby we can deliver small numbers of valves very quickly, typically within eight weeks. This service gives tremendous reassurance to EPC contractors as they know they can rely on us to keep their projects on target.” Bonney Forge’s definition of service also includes assisting customers who have unique requirements. “At WFI, we regularly receive calls from end users who are struggling to find lasting solutions for severe-service applications,” begins Mr. Heald. “They have seen how standard products can fail over time, so are looking for an engineered fitting that will deliver long-term performance. Sometimes the solution can be straightforward, such as modifying an existing design. However, in many cases our engineering team will design a unique product that is perfectly tailored for their specific application.”

Future plans

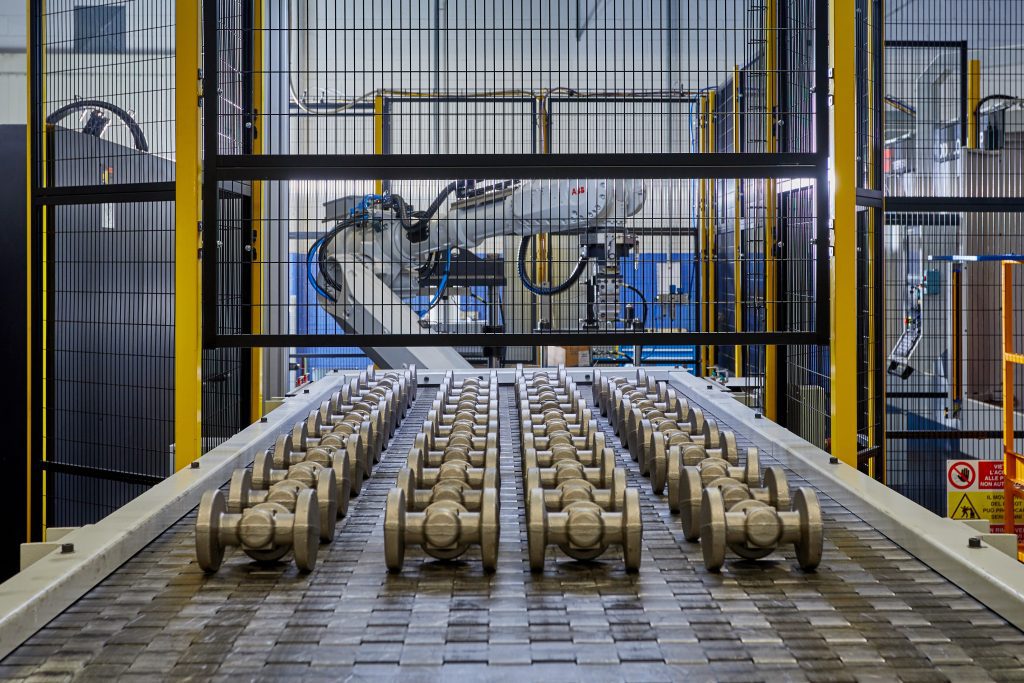

Since 1984, Bonney Forge has been owned by the Leone family. The company thereby benefits from prompt decision-making at the highest level in addition to strong financial support. “Take for example investments at our forged valve facility in Italy which boasts a high degree of automation with advanced CNC machines and robots. Automation has helped to speed up production rates while safeguarding quality – all made possible thanks to our owners,” states Mr. Sonzogni. Similarly, the two US locations can maintain extensive stock of raw materials, facilitating short production timelines for fittings and other components.

Support is also available to target new markets. Mr. Sonzogni: “Hence we recently engaged extra engineering and business development staff to promote our new ball valves. The latest models are ideal for critical applications in the energy and offshore platform sectors. With end user approvals having been gained, I am pleased to say first orders have already been shipped!”

Concludes Mr. Heald: “John Leone purchased Bonney Forge in 1984 and is the company’s CEO. Under his continued leadership, Bonney Forge has retained its leading position, enjoying persistent expansion and innovation. We were the original inventors of the branch connection and continue to build on and improve that initial prototype to this very day. The same holds true for all our valve offerings. Throughout all the company’s endeavors, we are looking ahead, deploying the latest technologies and investing for the future. But always with the customer’s needs in mind, and at all times focusing on our top-level goals, namely, to deliver on quality, service and value.”

Valve portfolio

- Gate valves

- Globe valves

- Check valves (piston, ball and swing)

- Ball valves (floating & trunnion-mounted)

- Double block and bleed valves

- API 594, 600, 602, 623, 6A, 6D valves

- Cryogenic valves

- Integral flanged end valves

- Bellows sealed valves

- Extended body gate

- Pressure seal valves

Dive Deeper into Valve World

Enjoyed this featured article from our May 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

- Advanced industry insights

- Expert analysis and case studies

- Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”