Many valve users rely on standard American Society of Mechanical Engineers (ASME) B16.34 pressure classes, often selecting valves based on material, pressure and temperature. However, for high-pressure weld end valves, this can lead to unnecessary costs. This article explores a lesser-known ASME provision that allows safe, cost-effective valve re-rating using design safety margins and NDE.

Mark Nord, Emerson

Most users who specify valves are quite familiar with the standard pressure classes defined by ASME B16.34. In many cases, a standard valve pressure class is chosen based on the valve material and the maximum process pressure and temperature, and the valve is simply ordered. While this works well for lower pressure classes (CL600 and less) and most flanged valves, this method can result in far higher costs than are necessary when applied to weld end valves in higher pressure and temperature applications. This article discusses a less common section

of the ASME B16.34 code that allows valve manufacturers, and purchasers, to take advantage of the large safety factors inherently built into some valve designs, along with non-destructive examination (NDE) testing to re-rate a standard valve to a higher pressure and temperature rating. In cases where process conditions exceed those offered by standard valve classes, the resulting reduction in cost, size and weight can be significant.

Table 10. For ASME Standard CL1500 Valves(1)

| SERVICE TEMP (°F) | WORKING PRESSURE (PSIG) | ||||||||||||||

| LCC | LF2 | WCC | WC6 | WC9 | C12A | CF8(2) or 304(2) |

CF8M(2) or 316(2) |

C3FM | 316 | CG8M | 317(2) | CF8C(2) | 347 | CK3MCuN CD3MN CD3MWCuN |

|

| -20 TO 100 200 300 400 500 |

3750 3750 3640 3520 3325 |

3705 3395 3270 3170 3015 |

3750 3750 3610 3465 3325 |

3750 3750 1610 3465 3325 |

3750 3750 3640 3530 3325 |

3750 3750 3640 3530 3325 |

3600 3600 2690 2485 2330 |

3600 3095 2795 2570 2390 |

3600 3095 2795 2570 2390 |

3000 2555 2280 2100 1970 |

3600 3095 2795 2570 2390 |

3600 3095 2795 2570 2390 |

3600 3310 3085 2880 2710 |

3600 3310 3085 2880 2710 |

3750 3720 3335 3070 2905 |

| 600 650 700 750 800 |

3025 2940 — — — |

2840 2745 2665 2535 2055 |

3025 2940 2775 2535 2055 |

3025 2940 2840 2660 2540 |

3025 2940 2840 2660 2540 |

3025 2940 2840 2660 2540 |

2210 2160 2110 2065 2030 |

2255 2210 2170 2135 2110 |

2255 2210 2170 2135 2110 |

1860 1825 1800 1765 1730 |

2255 2210 2170 2135 2110 |

2255 2210 2170 2135 2110 |

2580 2530 2485 2460 2435 |

2580 2530 2485 2460 2435 |

2785 2735 2710 2660 — |

| 850 900 950 1000 1050 |

— — — — — |

— — — — — |

— — — — — |

2435 2245 1595 1080 720 |

2435 2245 1930 1335 875 |

2435 2245 1930 1820 1800 |

1980 1945 1910 1770 1630 |

2090 2075 1930 1820 1800 |

2090— — — — |

1690 | 2090 2075 1930 1820 — |

2090 2075 1930 1820 1800 |

2425 2245 1930 1820 1800 |

2425 2245 1930 1820 — |

— — — — — |

| 1100 1150 1200 1250 1300 |

— — — — — |

— — — — — |

— — — — — |

480 — — — — |

550 — — — — |

1510 1115 720 — — |

1285 1030 825 670 565 |

1525 1185 925 735 585 |

— — — — — |

— — — — — |

— — — — — |

1525 1185 925 735 585 |

1560 1045 755 565 375 |

— — — — — |

— — — — — |

| 1350 1400 1450 1500 |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

465 380 290 205 |

480 380 290 205 |

— — — — |

— — — — |

— — — — |

480 380 290 205 |

255 205 155 135 |

— — — — |

— — — — |

| 1. Table information is extracted from the Valve — Flanged, Threaded and Welding End, ASME Standard B16.34-2013. These tables must be used in accordance with the ASME standard. The user is advised that a valve used under the jurisdiction of the ASME Boiler and Pressure Code, ASME Code for Pressure Piping, or governmental regulations is subject to any limitation of that code or regulation. This includes any maximum temperature limitation for a material or rule governing the use of a material at a low temperature. *Information copied with permission of the publisher; The American Society of Mechanical Engineers, 345 East 47th Street, New York, New York, 10017. 2. At temperatures over 1000°F, use material only when carbon content is 0.04% or higher. |

|||||||||||||||

Figure 2: This ASME Standard CL1500 valve chart shows the maximum allowable pressure and temperature ratings of Fisher CL1500 valves made of different materials.

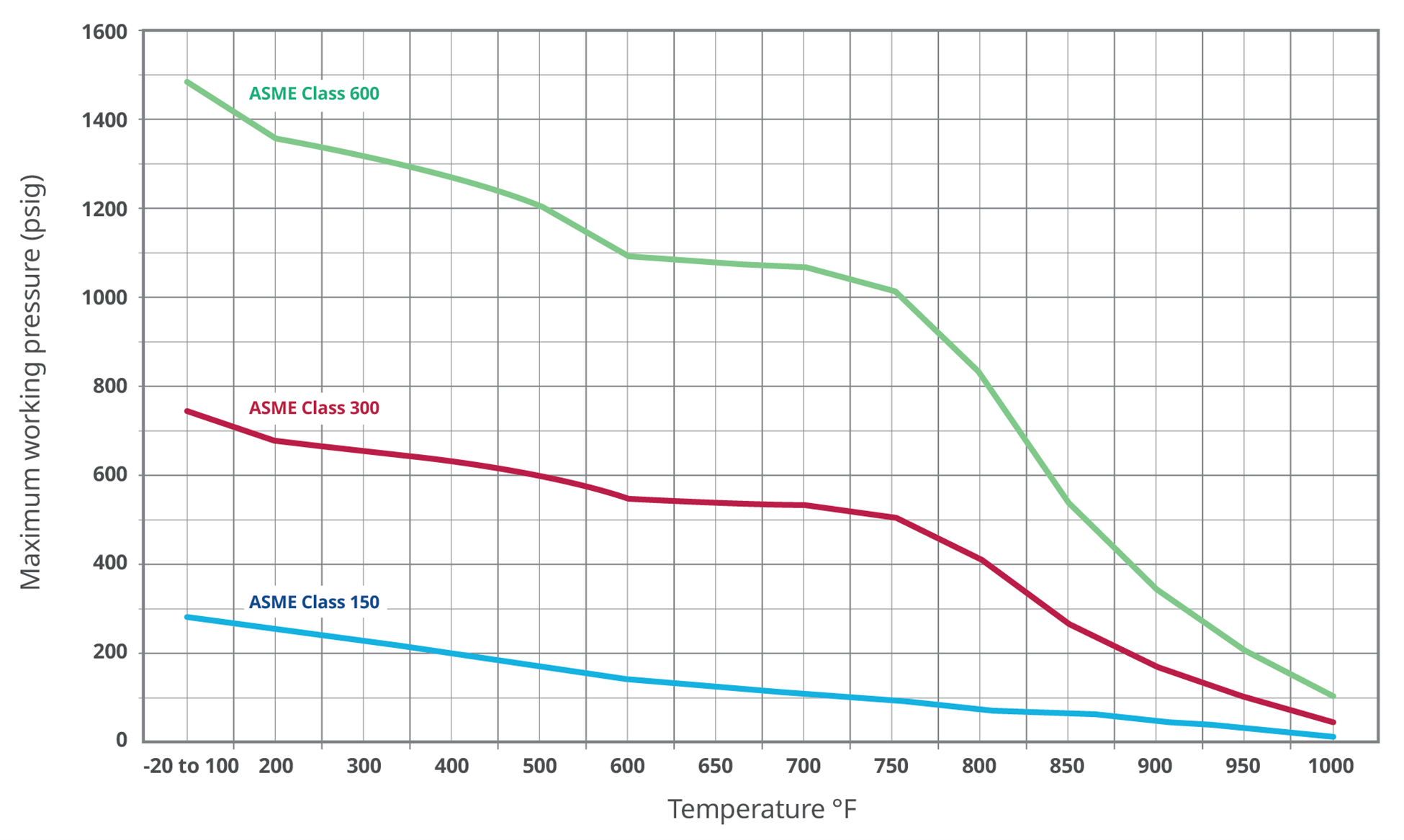

ASME Standard Class pressure ratings

Engineers who routinely select valves typically have a solid understanding of ASME standard pressure classes (Figure 1). As the chart shows, a carbon steel valve is capable of handling pressures significantly above the pressure class rating at ambient temperatures. However, as process temperatures rise, the maximum pressure rating falls. In the case of carbon steel, the maximum pressure drops precipitously above 800 °F.

Using the published standard class pressure/temperature charts, such as shown in Figure 2, end users can quickly compare their process requirements to the maximum process pressure and temperature ratings, and then select an ASME Standard Class valve that will meet those specifications. For instance, this chart indicates that a CL1500 WC9 (carbon steel) valve is rated for 3750 PSI at ambient temperature and 2245 PSI at 900 °F. If the maximum process pressure was above 2245 PSI at 900 °F, a higher-pressure class valve would be required.

The difference in cost and weight between the same size valves in the lower pressure classes is minor. But as one jumps from CL900 to CL1500, and even to CL2500, the difference in valve cost, size and weight becomes very significant.

For example, Figure 3 compares a 6” CL1500 valve to a 6” CL2500 valve. The valve cost and weight are nearly double, and the line take-out dimension stretches from 33” to 47”. In addition to the cost of the valve itself, the additional cost in pipe supports and the space required to fit the larger valve into the process piping adds to the overall cost escalation. This price difference is further magnified with larger valve sizes or non-standard alloys. Flanged valves generally fall under the ASME Standard Class ratings, so if a particular pressure class does not meet the design conditions, the user has little choice but to utilise a different material, if acceptable, or move up to the next pressure class. Fortunately, there are other ASME sanctioned alternatives when dealing with weld end valves.

In addition to ASME Standard Class valves, there are also ASME Special Class, ASME Intermediate Class and ASME Special Intermediate Classes available. Each of those options are discussed below.

Table 12. For ASME Special CL1500 Valves(1)

| SERVICE TEMP (°F) | WORKING PRESSURE (PSIG) | ||||||||||||||

| LCC | LF2 | WCC | WC6 | WC9 | C12A | CF8(2) or 304(2) |

CF8M(2) or 316(2) |

C3FM | 316L | CG8M | 317(2) | CF8C(2) | 347 | CK3MCuN CD3MN CD3MWCuN |

|

| -20 TO 100 200 300 400 500 |

3750 3750 3750 3750 3750 |

3750 3750 3700 3665 3665 |

3750 3750 3750 3750 3750 |

3750 3750 3750 3750 3750 |

3750 3750 3695 3640 3620 |

3750 3750 3750 3750 3750 |

3750 3350 3300 2770 2600 |

3750 3455 3120 2865 2665 |

3750 3455 3120 2865 2665 |

3350 2855 2545 2345 2195 |

3750 3455 3120 2865 2665 |

3750 3455 3120 2865 2665 |

3750 3585 3295 3105 3000 |

3750 3695 3440 3215 3025 |

3750 3750 3725 3430 3240 |

| 600 650 700 750 800 |

3750 3750 — — — |

3665 3575 3455 3170 2570 |

3750 3750 3565 3170 2570 |

3750 3750 3665 3645 3600 |

3605 3580 3535 3535 3535 |

3750 3750 3665 3645 3600 |

2465 2410 2355 2305 2265 |

2520 2465 2425 2385 2355 |

2520 2465 2425 2385 2355 |

2075 2035 2010 1970 1930 |

2520 2465 2425 2385 2355 |

2520 2465 2425 2385 2355 |

2880 2825 2770 2745 2720 |

2880 2825 2770 2745 2720 |

3105 3055 3025 3000 — |

| 850 900 950 1000 1050 |

— — — — — |

— — — — — |

— — — — — |

3385 2935 1995 1350 900 |

3385 3000 2360 1670 1095 |

3385 3000 2360 2105 2105 |

2210 2170 2130 2075 2035 |

2330 2315 2290 2105 2105 |

2330 — — — — |

1890 — — — — |

2330 2315 2290 2105 — |

2330 2315 2290 2105 2105 |

2705 2705 2360 2105 2105 |

2705 2705 2360 2105 — |

— — — — — |

| 1100 1150 1200 1250 1300 |

— — — — — |

— — — — — |

— — — — — |

600 — — — — |

685 — — — — |

1885 1395 900 — — |

1605 1285 1030 835 705 |

1905 1480 1155 920 730 |

— — — — — |

— — — — — |

— — — — — |

1905 1480 1155 920 730 |

1950 1305 945 705 470 |

— — — — — |

— — — — — |

| 1350 1400 1450 1500 |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

— — — — |

580 470 365 260 |

600 470 365 260 |

— — — — |

— — — — |

— — — — |

600 470 365 260 |

320 255 195 170 |

— — — — |

— — — — |

| 1. Table information is extracted from the Valve — Flanged, Threaded and Welding End, ASME Standard B16.34-2013. These tables must be used in accordance with the ASME standard. The user is advised that a valve used under the jurisdiction of the ASME Boiler and Pressure Code, ASME Code for Pressure Piping, or governmental regulations is subject to any limitation of that code or regulation. This includes any maximum temperature limitation for a material or rule governing the use of a material at a low temperature. *Information copied with permission of the publisher; The American Society of Mechanical Engineers, 345 East 47th Street, New York, New York, 10017. 2. At temperatures over 1000°F, use material only when carbon content is 0.04% or higher. |

|||||||||||||||

Figure 4: While ASME Special Class valves have the same pressure rating as Standard Class valves at ambient temperatures, they have elevated pressure ratings at higher temperatures.

Table 6. NPS 4 CL1500 HP Series Valves with CL2017 Intermediate Rating

| TEMPERATURE (°F) | VALVE BODY MATERIAL AND INTERMEDIATE CLASS DESIGNATIONS | MAX STEM LOAD, POUNDS(2) | |||||||||||

| WCC & LCC | WC9 | CFM8 | |||||||||||

| Pressure Rating | Pressure Rating (psig) | Pressure Rating (psig) | |||||||||||

| B7 | B7M | B7 | B7M | B16 | 718 | B7 | B7M | B8M-1 | B8M-2 | 660 | XM19 | ||

| 100 | 5045 | 5045 | 5045 | 5045 | 5045 | 4840 | 4840 | 15920 | |||||

| 200 | 5045 | 5045 | 5045 | 5045 | 5045 | 4165 | 4165 | 14200 | |||||

| 300 | 4895 | 4895 | 4895 | 4895 | 4895 | 3760 | 3760 | 12910 | |||||

| 400 | 4730 | 4730 | 4745 | 4745 | 4745 | 3455 | 3455 | 11610 | |||||

| 500 | 4470 | 4470 | 4470 | 4470 | 4470 | 3210 | 3210 | 10960 | |||||

| 600 | 4065 | 4065 | 4065 | 4065 | 4065 | 3035 | 3035 | 10460 | |||||

| 650 | 3955 | 3955 | 3955 | 3955 | 3955 | 2970 | 2970 | 10220 | |||||

| 700 | 3735 | 3735 | 3815 | 3815 | 3815 | 2920 | 2920 | 9970 | |||||

| 750 | 3410 | 3410 | 3575 | 3575 | 3575 | 2870 | 2870 | 9890 | |||||

| 800 | 2765 | 2765 | 3415 | 3415 | 3415 | 2840 | 2840 | 9800 | |||||

| 850 | 3260 | 3275 | 3275 | 2810 | 2810 | 5250 | |||||||

| 900 | 3020 | 3020 | 2790 | 5200 | |||||||||

| 950 | 2595 | 2595 | 2595 | 5160 | |||||||||

| 1000 | 1410 | 1800 | 2445 | 5110 | |||||||||

| 1050 | 1175 | 2420 | 5110 | ||||||||||

| Blank cell indicates an intermediate rating not available for this combination. Derating due to bolting limitation 1. Do not use LCC above 650°F. 2. Stem material is S31600 |

|||||||||||||

Figure 4: While ASME Special Class valves have the same pressure rating as Standard Class valves at ambient temperatures, they have elevated pressure ratings at higher temperatures.

ASME Special Class pressure ratings

In the case of weld end valves, some valve manufacturers offer ASME Special Class ratings. The ASME Standard Class ratings assume a base level of material and casting quality, which results in relatively conservative pressure and temperature ratings. However, most manufacturers can perform NDE testing on a specific valve body, and based on these test results, the ASME Code allows the manufacturer to rate the valve at higher pressures at elevated temperatures, even though the base level of material and casting quality does not change. For example, one can compare the Standard Class CL1500 chart in Figure 2 with the Special Class CL1500 chart in Figure 4. At ambient temperatures, both the Standard Class and Special Class valves have the same pressure ratings. But at higher process temperatures, the Special Class pressure ratings elevate considerably. A Standard Class CL1500 WC9 (carbon steel) valve is rated for 2245 PSI at 900 °F. The Special Class CL1500 WC9 valve is rated for 3000 PSI at that same temperature. If Special Class pressure ratings exceed the process requirements, the user can pay a relatively small extra charge for NDE testing, and they can then use a Special Class CL1500 valve instead of the much larger and more expensive Standard Class CL2500 valve. This saves significant money on the valve purchase itself, as well as reducing valve weight, space requirements and overall installation costs. Sometimes the Special Class pressure rating is still not enough to meet the process needs. In this case the user can consider an ASME Intermediate Class valve.

ASME Intermediate Class pressure ratings

Certain weld end valve body designs incorporate valve wall thickness exceeding that required by code. In these cases, some manufacturers can certify these valves to a higher-pressure class rating than Standard Classes. The specific pressure rating will depend upon the valve itself, as well as the material of construction, and the resulting pressure class will usually fall between the Standard Class ratings.

For instance, a Fisher HP series WC9 CL1500 valve could carry a CL2017 Intermediate rating. As Figure 5 shows, the pressure ratings at elevated temperatures may not be much higher than the Special Class CL1500 valve—in this case the Intermediate Class CL1500 rating at 900 °F is 3020 PSI versus 3000 PSI for the Special Class valve. However, there is a significant difference at ambient temperatures. As the chart indicates, the Intermediate Class CL2017 valve is rated for 5045 PSI at ambient temperatures versus 3750 PSI for the Standard and Special Class CL1500 valves.

An Intermediate Class valve does not require any additional NDE testing, but it is only offered in a limited range of weld end valve body styles. It does require the Standard Class pressure rating to be removed and replaced with a new pressure rating, so there is some additional cost, though less than the NDE testing and certification of a Special Class valve. Similar to the Special Class valve, an Intermediate Class alternative may present significant savings if it avoids having to move to the next pressure class rating.

ASME Intermediate Special Class pressure ratings

A third ASME approved pressure rating is the Intermediate Special Class. Essentially, this rating is a combination of the Special Class and Intermediate Class. Certain weld end bodies can be re-rated to an Intermediate Class, NDE testing can then be used to qualify for the Special Class rating as well. The net result is a valve that has pressure and temperature ratings higher than the Standard, Special and Intermediate ratings. While the cost for an Intermediate Special Class valve is higher than either the Special or Intermediate Classes, the ability to use this option can yield enormous savings, particularly for large valve body sizes.

Savings

Here are a few examples that illustrate the potential savings that can be achieved by taking advantage of the Special, Intermediate and Intermediate Special Class ratings. Note that these savings are only for the valve cost, and do not take into account additional savings realised by using these smaller and lighter valves.

- An application requires a 2” WC9 carbon steel valve at 1000 °F and 1428 PSIG.

- A Standard Class CL2500 valve would typically be required for this situation costing about $20,000.

- An Intermediate Class CL1694 valve would also work, costing about $14,000.

- Therefore, an Intermediate Class valve saves about $6,000.

- An application requires a 6” WC9 carbon steel valve at 1000 °F and 1570 PSIG.

- A Standard Class CL2500 valve would typically be required for this situation costing about $93,000.

- An Intermediate Class CL1876 valve would also work, costing about $59,000.

- Each Intermediate Class valve saves about $34,000.

- An application requires a 6” WC9 carbon steel valve at 1000 °F and 2030 PSIG.

- A Standard Class CL2500 valve would be required for this situation costing about $93,000.

- A Special Intermediate Class CL1876 valve would also work, costing about $59,000 + about $16,000 for additional NDE testing and certification.

- Each Special Intermediate Class valve saves about $18,000.

- As previously mentioned, the savings escalate quickly with larger valves or special alloys. An application required a 16” x 12” Valve in C12A martensitic stainless steel suitable for 1085 °F and 655 PSIG.

- Fisher had three options: quote an existing 16X12 2500# design, design a completely new 900# valve to meet the requirements, or see if our existing 600# design had any extra minimum wall thickness that would allow us to intermediate rate it, which it did.

- The existing Standard Class CL2500 valve, cost about $510,000.

- There was insufficient lead time to design a new CL900 valve.

- An Intermediate Class CL688 valve would also work, costing about $217,000. Large sizes like this are typically in a valve manufacturer’s portfolio, and were in this case, but they may not be available in all sizes

- The Intermediate Class valve saves about $293,000.

- Fisher had three options: quote an existing 16X12 2500# design, design a completely new 900# valve to meet the requirements, or see if our existing 600# design had any extra minimum wall thickness that would allow us to intermediate rate it, which it did.

Conclusion

When specifying weld end valves at elevated pressures and temperatures, end users would be wise to consult their valve vendor about ASME approved Special Class, Intermediate Class and Special Intermediate Class options. As indicated by the examples above, there are certain situations where these alternative class ratings can safely meet the process design conditions, while saving significant cost in the initial valve purchase price, as well as generating additional cost reductions from the decreased weight and size of the valves themselves.

Figures all courtesy of Emerson

About the author

About the author

Mark Nord is the control valve solution architect for Emerson’s Flow Controls Products in Marshalltown, Iowa. He is responsible for solving the most challenging control valve applications using his 35 years of experience in plant operation, control valve and steam conditioning applications. Nord holds a BSME degree from the University of North Dakota.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, June 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”

About the author

About the author