Pressure relief valves are critical safety components in boilers and pressure vessels, preventing excessive pressure build-up. This article explores key concepts like accumulation and overpressure, highlighting their roles in valve sizing, system protection, and compliance with ASME design codes.

By Artur Cardozo Mathias

Among the terminologies applied in pressure relief valves, we can mention accumulation and overpressure. Accumulation is the maximum pressure mong the terminologies applied in pressure relief valves, we can mention accumulation and overpressure. Accumulation is the maximum pressure allowed to be reached by a pressure relief valve at a value above the Maximum Allowable Working Pressure (MAWP) of the equipment being protected. Therefore, it is the increase in pressure allowed above the MAWP inside a boiler or pressure vessel, with all pressure relief valves completely open and relieving. Overpressure is the maximum pressure reached by the valve above its set pressure and according to the flow rate required by the process.

Therefore, the valve selected for a given application must have a maximum flow capacity that is equal to or greater than the worst cause of pressure generation source and flow volume, which prevents the pressure inside the equipment from exceeding the accumulation limits allowed by the design codes.

Accumulation in pressure vessels

The accumulation value allowed within a pressure vessel is a reference for the minimum number of pressure relief valves that can be installed and according to the causes of overpressure. In boilers, the accumulation value is fixed, therefore, independent of the number of valves installed.

Installation with multiple pressure relief valve

When overpressure is caused by an operational loss of control of the process, the accumulation allowed by ASME Code Section VIII is 10% or 3 psi (whichever is greater) for vessels protected by a single valve. When multiple pressure relief valves are installed, the maximum accumulation allowed by ASME is 16% or 4 psi (whichever is greater) above the MAWP. In these cases, if there are two or more valves installed, the second or last one must be adjusted to open at a maximum of 5% above the MAWP.

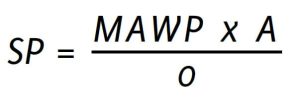

The opening pressure of the second or last pressure relief valve, if the pressure vessel (or boiler) is protected by two or more valves, can be determined as follows:

Where:

Where:

SP = opening pressure of the second or last valve

MAWP: Maximum Allowable Working Pressure of the vessel or boiler

A = maximum accumulation allowed for multiple valves, being 6% (1.06) for boilers and 16% (1.16) for pressure vessels

O = maximum allowable overpressure, being 3% (1.03) for boilers and 10% (1.10) for pressure vessels

Note: The allowable value of 3 psi accumulation is applied when the MAWP of the vessel is between 15 and 30 psig, and there is only one pressure relief valve installed. An allowable accumulation value of 4 psi is applied when the MAWP of the vessel is between 15 and 30 psig, and there are two or more pressure relief valves installed for its protection.

About the author

Arthur Mathias is an industrial mechanical and chemical technician and a Member of ISA. Now a consultant, he has been active since 1985 in the maintenance, inspection, specification and sizing of valves. Arthur provides training and technical courses, and is the author of Válvulas: Industriais, Segurança e Controle published by ARTLIBER EDITORA.

Fire conditions

If the vessel is protected by two valves, one only to respond to an operational loss of control, it must be set at or below MAWP, and the second (supplementary valve), to respond to a fire condition external to the vessel, must be set at 10% above MAWP and have the nozzle area also dimensioned for 10% overpressure. This valve must prevent, even under fire conditions, the pressure inside the vessel from developing to a value greater than 21% of MAWP.

Note: Pressure vessel designers must establish the 10%, 16% or 21% accumulation limits, assessing that the allowable stress reduction with the increase in temperature is still within the safety factors applied by the design codes (between 3 and 5 times).

The accumulation values, for all the situations mentioned, mean that with all the pressure relief valves open and relieving, the pressure inside the protected equipment cannot exceed those percentages. Accumulation is, therefore, the primary parameter when sizing a pressure vessel or boiler, and is expressed as a percentage of the MAWP of that equipment.

Note: Each section of the ASME code (I, IV, and VIII) provides its own rules regarding the percentage of pressure allowed to be raised above the MAWP of the equipment to be protected by the pressure relief valve during a process overpressure event.

Note: A supplemental pressure relief valve for “fire conditions” is a pressure relief device that provides a much higher flow capacity than the one that was sized and installed only to meet the flow capacity required by the process. It should always be applied when an additional hazard may be generated to a pressure vessel by its exposure to fire or another unexpected source of external heat. Therefore, the supplemental pressure relief device is only applied to devices already sized and installed for situations of operational loss of control, such as chemical reaction, blocked discharge, etc. The value of its opening pressure cannot exceed 110% of the vessel’s MAWP.

The accumulation percentage is a value that depends only on the MAWP value of the vessel, the causes of the overpressure and the number of valves installed, and is independent of the opening pressure value of the safety and/or relief valve(s) that protect it.

Accumulation in boilers

In boilers built in accordance with ASME Section I, the maximum allowable accumulation is 6% above MAWP, regardless of the number of pressure relief valves installed. Therefore, no more than 6% above the highest pressure at which any pressure relief valve is set to open, i.e., when set below MAWP, or no more than 6% above the boiler MAWP is allowed (PG 67.2).

PG 67.3 of the ASME Section I code allows the second or last valve to be set to open up to 3% above the boiler MAWP.

Overpressure

Overpressure is the same as accumulation only when the pressure relief valve is set to open at the same value as the MAWP of the pressure vessel or boiler, and there are no pressure losses in the inlet piping. The value of the overpressure depends on the construction code of the equipment to be protected and the value of the valve opening pressure. For example, for boilers that are built according to ASME Section I, this value is 3% or 2 psi, whichever is greater, both in the steam drum and in the superheater.

Overpressure is the same as accumulation only when the pressure relief valve is set to open at the same value as the MAWP of the pressure vessel or boiler, and there are no pressure losses in the inlet piping. The value of the overpressure depends on the construction code of the equipment to be protected and the value of the valve opening pressure. For example, for boilers that are built according to ASME Section I, this value is 3% or 2 psi, whichever is greater, both in the steam drum and in the superheater.

For pressure vessels built according to ASME Section VIII and process piping built according to ASME B31.3, the overpressure value must be 3 psi or 10% above the valve opening pressure (whichever is greater), for gases, vapors and liquids. Overpressure is mainly necessary in valves with a spring under load and operating with compressible fluids, since the disc does not reach the maximum lift at the opening pressure, due to the increasing force exerted by the spring in the downward direction and opposite to the opening direction. Therefore, it is an increase in pressure above the opening pressure, necessary for the valve disc to reach its maximum lift, and, consequently, for the valve to reach its maximum flow capacity, i.e., the flow will be limited by the nozzle throat area.

Note: This is the overpressure acting on the area of the external diameter of the nozzle ring (when this ring is correctly positioned), and the huddling chamber is what allows the disc to reach its maximum lift. The positioning of this ring can change both the disc’s lifting stroke and the overpressure value achieved in relief conditions, in addition to changing the valve’s closing pressure value.

Thus, the overpressure exists to allow the pressure inside the nozzle and huddling chamber to overcome the increasing force exerted by the spring. The chattering that occurs due to oversizing is due to there being no overpressure inside the huddling chamber during the valve relief process. Overpressure is the difference between the accumulation existing inside the pressure vessel or boiler and the valve opening pressure. Therefore, the value of the overpressure depends on the flow capacity required by the process in relation to the maximum flow capacity of the valve. However, it is at the percentage of overpressure required by the building code that the nominal flow capacity of the valve is achieved.

If the valve opening pressure is lower than the MAWP of the vessel, the overpressure may be greater than 10%, provided that the maximum accumulation reached during relief does not exceed 10% or 3 psi of the MAWP of the vessel. Thus, for example, a pressure vessel whose MAWP is equal to 100 psig (7.03 kgf/cm2) and the pressure relief valve is adjusted to open at 90 psig (6.3 kgf/cm2), the maximum overpressure reached by the valve under relief conditions may be up to 20%, since (100 x 1.1) – 90 = 20, however, the accumulation limit value will not be exceeded.

Note: an overpressure greater than 10% of the opening pressure is not permitted by ASME Section VIII, but is permitted by API Std. 520 Part I.

Conclusion

When a vessel is protected by two or more pressure relief valves, the pressure increase above the opening pressure of the primary valve is the overpressure, if it is set below the MAWP of the vessel. For the other pressure relief valves being set to open from the MAWP of the vessel, the pressure increase above the opening pressure (and above the MAWP) is called accumulation. The percentage of overpressure is a value dependent only on the value of the opening pressure of the pressure relief valve, the flow required by the process in relation to the maximum flow capacity through the selected area of the nozzle, in addition to the correct positioning of the nozzle ring. While accumulation is a term referring to the causes of overpressure and the number of pressure relief valves installed, acting at a value equal to or above the MAWP of the equipment being protected.

When a vessel is protected by two or more pressure relief valves, the pressure increase above the opening pressure of the primary valve is the overpressure, if it is set below the MAWP of the vessel. For the other pressure relief valves being set to open from the MAWP of the vessel, the pressure increase above the opening pressure (and above the MAWP) is called accumulation. The percentage of overpressure is a value dependent only on the value of the opening pressure of the pressure relief valve, the flow required by the process in relation to the maximum flow capacity through the selected area of the nozzle, in addition to the correct positioning of the nozzle ring. While accumulation is a term referring to the causes of overpressure and the number of pressure relief valves installed, acting at a value equal to or above the MAWP of the equipment being protected.

Therefore, overpressure is a term referring to the valve opening pressure, while accumulation is a term referring to the MAWP of the pressure vessel or boiler. The amount of overpressure could be infinite, depending on the cause(s) of the pressure increase, if not limited by a correctly specified, sized, inspected and maintained pressure relief valve.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, June 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”