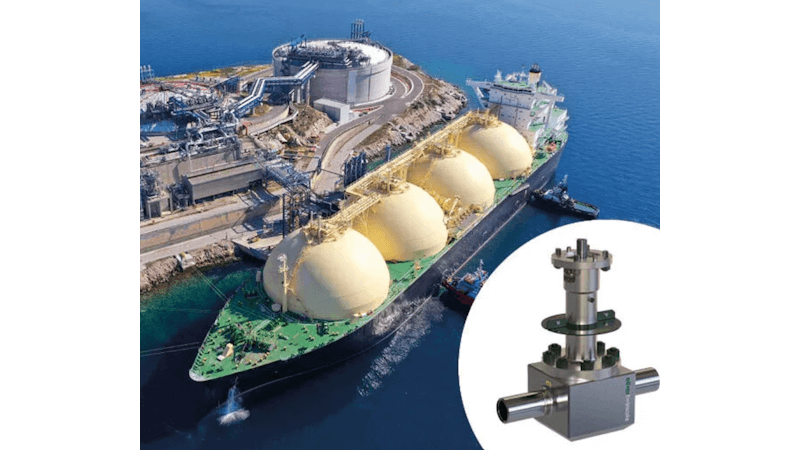

Oliver Twinsafe has expanded its product range with the introduction of a top entry cryogenic ball valve, purpose-built for low-temperature and sour gas applications. Developed in response to growing demand across the LNG, industrial gas, and petrochemical sectors, the new valve combines robust design with in-line serviceability, offering performance and reliability in some of the most challenging operating environments.

At the heart of the design is a top entry, extended bonnet construction that ensures safe and efficient operation at cryogenic temperatures, while also allowing in-line access to internal components for maintenance and inspection. This reduces system downtime and simplifies service routines—key advantages in process-critical environments.

Available in floating and trunnion-mounted configurations, the valve is fully compliant with API 6D, ISO 15848 Cl.AH, NACE MR0175 and ASME B31.3 CAT. M. Metal seated options and hardfaced trims are also available for applications involving severe wear or thermal cycling.

The top entry cryogenic valve joins Oliver Twinsafe’s existing cryogenic portfolio, which includes floating ball valves and side-entry trunnion designs, offering customers a complete package of high-integrity isolation solutions for LNG and beyond.