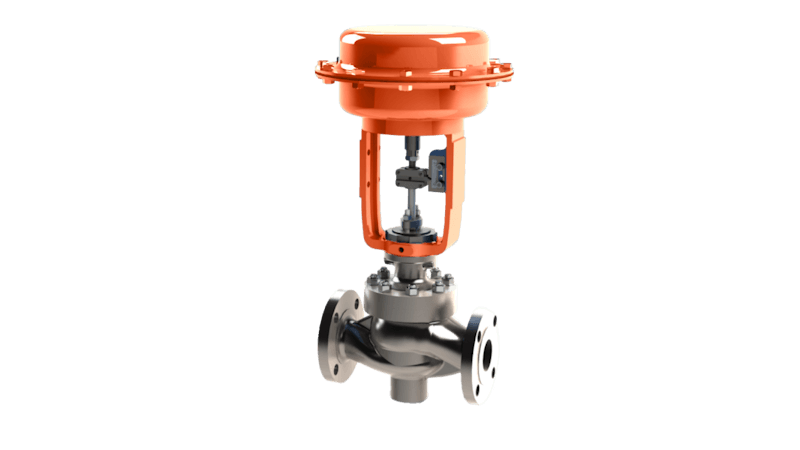

To meet customer demand, the Copes-Vulcan brand has introduced a new control valve for reliable, efficient flow control in general service applications. Further extending its valve portfolio, the Copes-Vulcan CVK Globe Control valve provides a cost-effective solution to the “final control element” in applications such as modern power plants, industrial plants, and oil & gas. It can be used to stop, start, and regulate the flow of liquids and gases in many flow control applications, including pipelines for water, steam, or chemical processing systems.

With a proven design and high capacity, the CVK Globe Control valve offers excellent efficiency, reliability, and precise control performance. Its high capacity-to-body size ratio ensures optimal performance in a compact and lightweight unit, saving space and simplifying installation. Streamlined flow passages provide superior capacity, reducing energy losses and enhancing overall system efficiency. Additionally, its excellent flow control rangeability enables highly accurate flow control.

Available in sizes ranging from ½” (15mm) to 8” (200mm), and ANSI classes 150 to 600, the CVK Globe Control valve regulates fluid flow in a pipeline by moving a plug up and down inside the valve body. The plug is attached to a stem, which is operated by an actuator such as a diaphragm, pneumatic, electric, or manual type. As the plug moves toward or away from a sealing surface called the seat, it adjusts the size of the opening that fluid can pass through. This allows for precise control of flow depending on how far the valve is opened. Globe valves are commonly used in applications that require accurate and reliable flow regulation.