Marotta Controls, a rapidly growing aerospace and defence supplier, has reached a major milestone in advanced manufacturing with the successful installation of its additively manufactured component aboard a US Navy ship. The installation marks a breakthrough in accelerating additive manufacturing (AM) technologies from prototype to active-duty deployment, reinforcing the Navy’s push for supply chain modernisation and fleet readiness.

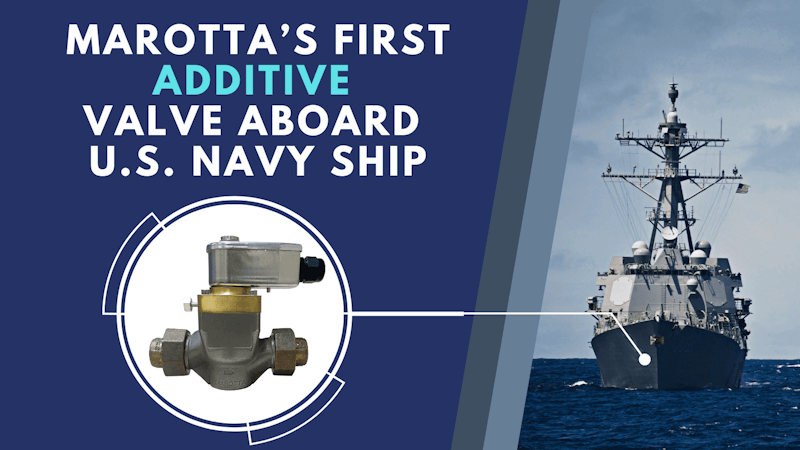

The chilled water valve (Model MV286A) was installed in April 2025 aboard a US Navy surface ship as part of a Navy-sponsored initiative to integrate additive manufacturing technology into fleet operations. The effort was funded by the Maritime Sustainment Technology and Innovation Consortium (MSTIC), a U.S. Navy OTA program focused on strategic introduction of advanced manufacturing solutions to the fleet.

The initiative began as a targeted response to longstanding supply chain challenges. Marotta selected the MV286A valve body as a candidate for redesign due to its historically long procurement time—29 weeks for a traditional sand-cast brass body—and significant quality control issues related to porosity and part rejection rates.

Marotta’s engineering team replaced the brass valve body with a requalified version produced via Laser Powder Bed Fusion (LPBF) using Inconel 625, a corrosion-resistant nickel superalloy. The result: a 70% reduction in lead time and a higher-performance component that met rigorous Navy requirements, such as high-impact shock per MIL-S-901E and vibration per MIL-STD-167-1, with ease.

NAVSEA approved the qualification reports, allowing shipboard integration. Three valves were installed as part of the MSTIC effort, offering both operational value and a validation point for broader AM adoption within naval systems.