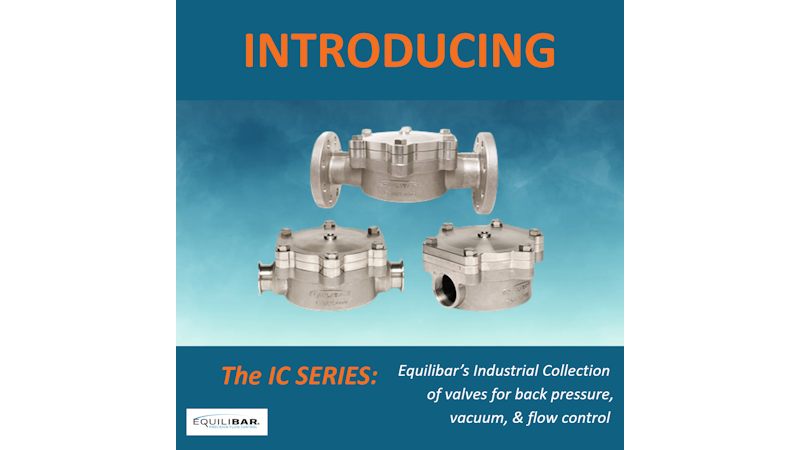

Equilibar has launched the IC Series, a new Industrial Collection of valves for back pressure, vacuum, and flow control applications with high throughput.

Featuring its dome-loaded multiple-orifice technology, these valves and regulators provide best-in-class performance in a practical, compact size. They are easily customized for a variety of applications and are well suited for demanding gas, liquid, and mixed phase fluid applications that involve high Valve Flow Coefficient (Cv).

Key Advantages of the IC Series include: Short lead times – Standard lead times of 2-3 weeks are available for in-stock valves; High pressure options – A new offering of class 150 and 300 designed to ASME B16.34 standards allows drop-in replacement of underperforming valves from other brands. Premium materials –Dual-certified CF3M/1.4409 stainless steel body material is standard, with Hastelloy and most nickel-based alloy options available upon request. Flexible process connection options – NPT, ANSI RF flange, and tri-clamp fittings are standard and in stock. DIN flanges, BSPP threaded ports, and other connections are available upon request.

The IC Series features Equilibar’s revolutionary dome-loaded multiple orifice technology. The synergistic design of these valves offers virtually instantaneous control and unprecedented precision for even the most challenging process conditions.

A supple diaphragm is the Equilibar® regulator’s only moving part, enabling frictionless operation. Because it is dome-loaded, it provides reliably stable pressure control. At the same time, the multiple orifice design results in an ultra-wide flow range.

Port sizes for the IC Series are available from 1.5″ to 3″ standard, with custom sizes on request.