A globally recognised expert in energy, industry and technology, Irawan Josodipuro, celebrated for his innovations and contributions, presents his Holistic Precision Qualification, Inspection and Test Plan (HP-QITP) approach. This framework addresses valve reliability across all lifecycle phases. The plan reinforces safety, performance and compliance in the demanding oil & gas sector through rigorous inspection and testing protocols.

By Irawan Josodipuro, Subject Matter Expert at Pertamina

Valve reliability is fundamental to operational sustainability in the oil and gas industry, where valves serve as critical control points across upstream, midstream and downstream operations. These components must maintain the controlled flow of hydrocarbons under extreme service conditions including high pressure, high temperature (HPHT) and corrosive or erosive environments. Under such harsh conditions, valves are prone to material degradation, mechanical failures and performance inefficiencies, all of which can lead to unplanned shutdowns, environmental hazards, safety incidents and significant economic losses. An old saying captures the essence of this approach: “You get what you inspect, not what you expect.” In high-stakes industrial environments, relying on assumptions or incomplete assessments can result in overlooked vulnerabilities and costly consequences. The HP-QITP framework embraces this mindset, emphasising the importance of proactive, precise and continuous inspection to ensure that valves perform as intended under real-world operating conditions.

What is the HP-QITP approach?

HP-QITP stands for Holistic Precision – Qualification, Inspection, and Test Plan. This approach is designed to ensure that every aspect of valve quality is not only thoroughly qualified but also rigorously inspected and tested. The aim is to confirm that the product is fit for purpose, meeting requirements for quality, safety, performance standards and reliability through a precise and methodical approach.

HP – Holistic Precision

Holistic: Involves examining the entire process and all influencing factors throughout the product’s life cycle.

Precision: Focuses on the accuracy and exactness of measurements, tests and inspections.

This dual focus ensures that the valve is reliable and fit for purpose.

Q – Qualification

Emphasises process control to ensure the product consistently meets standards and requirements. Includes steps such as prototyping, validation and maintaining product consistency.

This phase certifies that the valve complies with technical and safety specifications.

ITP – Inspection and Test Plan

Comprises a structured set of procedures, criteria and guidelines used during inspection and testing.

It is focused on verifying quality at various stages of manufacturing and before delivery.

The ITP ensures that every product is inspected thoroughly and meets predefined acceptance criteria.

| Description | HP-QITP | Common ITP | No Inspection |

| Quality | ☑ High-quality assurance through integrated, system-wide checks

☑ Considers process interdependencies and precision standards |

⚠ Moderate quality control with standard procedures

⚠ Less sensitivity to process variations |

✘ Inconsistent quality control

✘ Lacks structure and completeness |

| Cost | ☑ Cost-saving over time via reduced rework, defects and calls

☑ Efficient resource allocation |

⚠ Moderate cost efficiency

⚠ Some rework due to missed checks |

✘ High hidden costs from defects and delays

✘ Reactive fixes are expensive |

| Delivery | ☑ Optimised for on-time delivery due to proactive risk management

☑ Real-time tracking and corrective action |

⚠ May meet deadlines but risk delays due to overlooked issues | ✘ Frequent delays from unmanaged risks and late defect discovery |

| Safety & Reliability | ☑ High process and product reliability and safety

☑ Data-driven and repeatable |

⚠ Moderate safety & reliability for routine tasks

⚠ May lack robustness for complex systems |

✘ Unreliable outputs

✘ Inconsistent practices and outcomes |

Figure 1: Benefit of HP-QITP vs Common ITP vs No Inspection

What is the benefit of HP-QITP?

The Holistic Precision Quality Inspection and Test Plan (HP-QITP) demonstrably surpasses both common ITPs and the absence of proper inspection across critical business aspects.

In terms of Quality, HP-QITP delivers superior assurance through integrated, system-wide checks that consider process interdependencies and precision standards. This stands in stark contrast to common ITPs, which offer only moderate quality control with standard procedures and less sensitivity to variations, and is a vast improvement over no inspection, which results in inconsistent quality control and a lack of structure and completeness.

Regarding Cost, HP-QITP drives significant savings over time by reducing rework, defects and recalls, along with efficient resource allocation. This is a considerable advantage over common ITPs, which offer only moderate cost efficiency and may incur some rework due to missed checks. The benefits are even more pronounced when compared to no inspection, which leads to high hidden costs from defects, delays and expensive reactive fixes.

For Delivery, HP-QITP optimises on-time performance through proactive risk management, real-time tracking and corrective action. This provides a clear edge over common ITPs, which may meet deadlines but risk delays due to the overlooked issues. It also completely mitigates the frequent delays experienced with no inspection, which are caused by unmanaged risks and late defect discoveries.

Finally, concerning Safety & Reliability, HP-QITP ensures high process and product reliability and safety through a data-driven and repeatable approach. This is superior to common ITPs, which offer only moderate safety and reliability for routine tasks and may lack robustness for complex systems. Critically, it prevents the unreliable outputs and inconsistent practices and outcomes inherent in the absence of proper inspection. This paper introduces a structured and research-based framework: the Holistic Precision Qualification, Inspection, and Test Plan (HP-QITP). This strategic model is designed to enhance valve reliability and ensure long-term performance across the entire asset lifecycle—from design and prototyping to manufacturing, project execution, field operation and maintenance. The HP-QITP framework integrates rigorous inspection and testing protocols with industry best practices and compliance standards (ASME, API, ISO, NACE, among others), providing a comprehensive solution for validating valve performance under a range of operational scenarios.

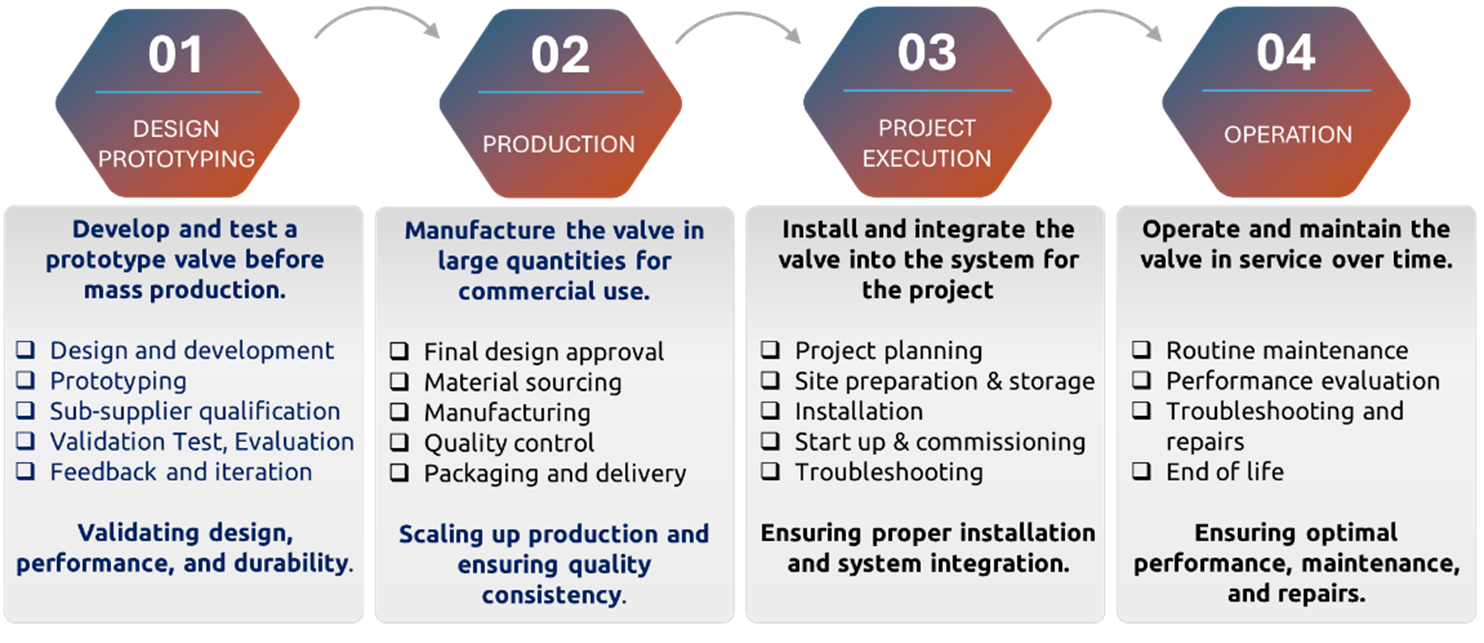

The valve asset lifecycle starts from design and prototyping to manufacturing, project execution and field operation. The objective, activities and key focus is different among these cycles and can be seen in Figure 1. The valve lifecycle is structured into four principal phases: design prototyping, production, project execution and operation, each critical to ensuring valve performance, reliability and longevity.

In the design prototyping phase, the objective is to develop and validate a prototype valve prior to mass production. Key activities include detailed design and development, prototyping, sub-supplier qualification, validation testing and iterative improvements. The primary focus is on verifying the valve’s design integrity, operational performance and mechanical durability under simulated conditions.

The production phase focuses on the large-scale manufacturing of valves for commercial deployment. Activities encompass final design approval, material sourcing in accordance with specifications, manufacturing, quality assurance procedures and packaging

for delivery. This phase emphasises scaling up production capabilities while ensuring strict adherence to quality and performance standards.

During the project execution phase, valves are installed and integrated into operational systems. Activities include detailed project planning, site preparation and logistics, installation, commissioning and initial troubleshooting. The focus is on ensuring correct installation practices and seamless system integration to prevent operational failures.

The operation phase covers the full-service life of the valve. This includes routine maintenance schedules, performance monitoring, troubleshooting, corrective repairs and end-of-life procedures. The key focus is sustaining optimal valve functionality, minimising downtime and achieving maximum operational life through effective maintenance strategies.

A structured approach across all phases is essential to guarantee valve reliability, safety compliance and performance efficiency throughout its intended operational lifespan.

HP-QITP Framework

The HP-QITP (High-Performance Quality Inspection and Testing Plan) Framework defines a comprehensive approach to valve quality assurance throughout all phases of the valve lifecycle: design prototyping, production, project execution and operation.

1. Scope

During the design prototyping phase, small-scale testing is conducted on prototype units to validate initial design concepts. In the production phase, batch-based quality control is applied to ensure consistency across manufactured valves. The project execution phase focuses on procurement verification, delivery assessment and installation checks. Finally, during the operation phase, routine inspections and maintenance activities are carried out to sustain valve performance over time.

2. Material verification

Material verification is critical at each phase. During design prototyping, 100% material verification along with mill certificate validation is performed. In production, verification is conducted on a per batch sample basis. Project execution demands full traceability of materials used, while in operation, inspections target potential wear, corrosion and seal integrity issues.

3. Dimensional inspection

Comprehensive dimensional measurements are carried out during design prototyping to ensure design conformity. In the production phase, dimensional inspections are conducted per batch sample. Project execution focuses on verifying compliance with specified design and operational requirements. During operation, inspections aim to identify wear, deformation and misalignment.

4. Visual inspection

Design prototyping involves a 100% detailed visual examination of prototype units. During production, every unit undergoes full visual inspection. In the project execution phase, visual inspections are performed prior to shipment to ensure product integrity. In the operation phase, routine checks are conducted to detect leaks, cracks and corrosion.

5. Welding inspection

All welds are subjected to 100% inspection and qualification during the design prototyping phase. Production weld inspections are performed, depending on the criticality, per batch sample or full product to maintain weld quality. Project execution requires compliance with welding standards and specifications. In the operation phase, weld integrity is monitored to detect service-related degradation.

6. Non-Destructive Testing (NDT)

Design prototyping mandates 100% non-destructive testing, including surface and volumetric examinations. During production, depending on the criticality, partial or full NDT could be performed on either a batch sampling basis or full product. Project execution focuses NDT efforts on critical areas, as specified by project requirements. In the operation phase, NDT is utilised to detect internal defects, particularly when failure or suspected anomalies occur.

7. Pressure test

Extreme variation pressure testing is conducted during design prototyping to validate valve performance under different operational conditions. Production follows standard pressure test requirements. In the Project execution phase, pressure tests are conducted in accordance with project-specific demands. During operation, pressure testing is performed after major repairs to confirm restored integrity.

8. Seat leak test

Seat leak testing during design prototyping includes both incremental and decremental pressure variations to thoroughly evaluate sealing performance. Production involves 100% seat leak testing on all units. Project execution verifies seat leakage before shipment. During operation, seat leak tests are conducted after seal replacements or repairs to ensure proper sealing function.

9. Functional testing

During the design prototyping phase, comprehensive functional tests are conducted under extreme conditions representing operating condition, assessing torque, flow, actuation and cycling performance. In the production phase, standard functional tests are applied per batch. During project execution, functional validation is confirmed during valve start-up and commissioning. In the operation phase, functional tests are performed after maintenance or repair activities.

10. Cycle testing (endurance testing)

Extended cycle testing, involving up to 10,000 cycles or more, is executed during design prototyping to assess durability under repeated operation. In production, endurance testing is conducted on a sample basis to verify operational robustness. Project execution may include endurance testing depending on specific project requirements, while in the operation phase, such tests may be performed to investigate recurring operational failures.

11. Failure testing (destructive testing)

Failure limits are determined during design prototyping through destructive testing methodologies. In production, limited destructive testing is carried outon representative samples. During project execution, destructive testing is conducted only if specifically required by the project specifications. Within the operation phase, destructive testing is performed if failure analysis is deemed necessary.

12. Certification and marking

The design prototyping phase ensures compliance with certification requirements such as fire safety, fugitive emissions, health, safety and environmental (HSE) standards. During production, full material traceability, batch fugitive testing and verification are maintained. Project execution confirms full traceability and regulatory compliance. During operation, certification traceability is reassessed, particularly after repair or re-certification activities.

13. Final inspection and approval

Final inspections during Design Prototyping involve R&D, engineering and quality assurance sign-off. In production, quality assurance/quality control (QA/QC) and third-party inspections are mandatory prior to shipment. During project execution, approval is obtained from clients and relevant regulatory bodies. In the operation phase, final validation checks are performed following maintenance and repair works.

14. Regulatory compliance

Across all phases, strict adherence to recognised standards such as API, ASME, ASTM and ISO is required. During project execution, compliance extends to site-specific regulatory frameworks, such as OSHA. Operation phase activities ensure ongoing compliance with maintenance and health and safety standards.

15. End result

The end goal of the design prototyping phase is the validation of valve designs prior to mass production. Production activities result in fully production-ready valves. During project execution, valves are fully tested, certified and documented to meet project requirements. The operation phase culminates in a fully functional and operational valve, sustaining long-term performance and safety.

FRAMEWORK |

||

| 1. SCOPE | 6. NDT INSPECTION | 11. FAILURE TEST |

| 2. MATERIAL VERIFICATION | 7. PRESSURE TEST | 12. CERTIFICATION |

| 3. DIMENSIONAL INSPECTION | 8. SEAT LEAK TEST | 13. FINAL INSPECTION |

| 4. VISUAL INSPECTION | 9. FUNCTIONAL TEST | 14. REGULATORY |

| 5. WELDING INSPECTION | 10. ENDURANCE TEST | 15. END RESULT |

Figure 3: HP-QITP Framework

Conclusion

Having established the HP-QITP Framework, the crucial next step involves formulating key inspection processes tailored to each valve life cycle phase. These processes will integrate code and standard requirements, specifications, best practices and lessons learned derived from critical inspection findings prevalent in each phase. Further development of these intricate details requires deep practical knowledge, which is precisely where Valve Subject Matter Experts (SMEs) become invaluable. Their extensive experience and specialised insights are essential for validating and refining the formulated inspection processes, identifying potential gaps or inefficiencies, ensuring the practicality and applicability of procedures in real-world scenarios, and incorporating a nuanced understanding of specific valve types, operating conditions and failure modes that might not be explicitly covered in standards. By leveraging the expertise of valve SMEs, the HP-QITP Framework can evolve into a robust and highly effective system, directly contributing to enhanced safety and operational reliability.

About the author

Irawan Josodipuro is an accomplished subject matter expert with more than three decades of experience in piping, valves, pressure vessels and mechanical equipment. He holds a Master’s degree in Mechanical Engineering from Stanford University and multiple professional certifications. Throughout his career, he has led major national and international projects and operations in the energy and the oil & gas industry, collaborating with leading industry players and regulatory authorities. In addition, Irawan is widely recognised for his ability to advise industry stakeholders on bridging quality and performance gaps to meet the stringent requirements of international and national energy, oil and gas operators. His insights into compliance, engineering integrity and operator expectations make him a valuable partner for companies aiming to qualify, improve or expand their market presence.

Irawan Josodipuro is an accomplished subject matter expert with more than three decades of experience in piping, valves, pressure vessels and mechanical equipment. He holds a Master’s degree in Mechanical Engineering from Stanford University and multiple professional certifications. Throughout his career, he has led major national and international projects and operations in the energy and the oil & gas industry, collaborating with leading industry players and regulatory authorities. In addition, Irawan is widely recognised for his ability to advise industry stakeholders on bridging quality and performance gaps to meet the stringent requirements of international and national energy, oil and gas operators. His insights into compliance, engineering integrity and operator expectations make him a valuable partner for companies aiming to qualify, improve or expand their market presence.

He is also deeply committed to mentoring engineers and promoting industry alignment with global standards and regulatory frameworks. His innovative contributions have earned him numerous accolades, including the SatyaLancana Wira Karya medal from the President of the Republic of Indonesia, as well as recognition from international institutions.

Dive Deeper into Valve World

Enjoyed this featured article from our September 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

Advanced industry insights

Expert analysis and case studies

Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”