In part two to this series, Fadila Khelfaoui and Luc Vernhes explain how VEL-8 is a next-generation ceramic coating designed for extreme hydrometallurgical conditions. With patented composition and advanced thermal spray technology, it offers superior corrosion, wear, and crack resistance—delivering extended service life and reduced maintenance in HPAL and POx operations.

By Fadila Khelfaoui and Luc Vernhes, Velan

VEL-8 is a patented, advanced ceramic coating specifically engineered for severe-service hydrometallurgy. Its proprietary blend delivers superior corrosion resistance, wear performance and mechanical toughness, addressing the main failure modes of earlier generations. Unveiled at ALTA in 2018, VEL-8 underwent extensive lab and field trials between 2019–2020 and was fully industrialised by 2021. What truly sets VEL-8 apart is not just its composition but how it’s applied. A specialised thermal spray system was selected to achieve ideal coating characteristics:

- High particle velocities—up to 3x that of conventional Air Plasma Spray (APS) torches—yield a denser and more adherent coating

- Elevated particle temperatures ensure better bonding and microstructural cohesion

- Minimal contamination risk, unlike some HVOF systems, enhances consistency

This combination results in a crack-resistant, high-integrity coating capable of withstanding the most aggressive chemical and mechanical conditions in HPAL and POx operations.

VEL-8 performance under laboratory testing

VEL-8 was benchmarked in the laboratory against legacy coatings, including VEL-CL, Velan’s widely used solution for HPAL and POx applications. A comprehensive test matrix was executed using both standardised and advanced evaluation methods, including:

Tribological testing (ASTM G65 & G105)

testing.

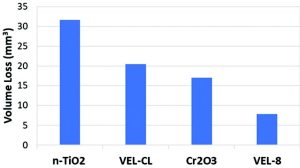

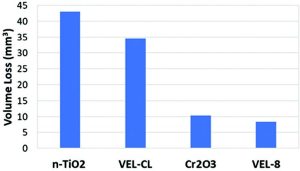

Dry and wet sand abrasive wear tests, conducted in accordance with ASTM G65 and ASTM G105 standards, simulate typical erosive environments encountered in slurry-handling systems. These standardised tests evaluate wear resistance by measuring the volume loss of material under controlled abrasive conditions. Together, these tests provide a comprehensive assessment of a coating’s ability to resist both dry particle impingement and slurry-driven erosion—key degradation mechanisms in HPAL and POx service. VEL-8 showed best-in-class performance in both dry and wet sand abrasion tests.

- Dry sand abrasion: VEL-8 exhibited the lowest volume loss, confirming outstanding wear resistance in dry, high-impact applications (Figure 3).

- Wet sand abrasion: VEL-8 achieved a 5x lower wear rate than nano-structured TiO2, validating its durability under continuous slurry exposure (Figure 4).

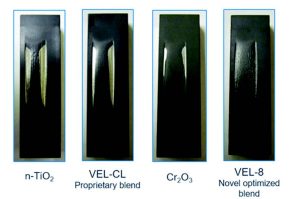

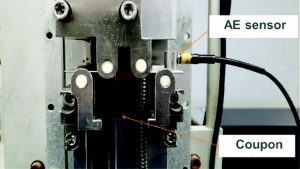

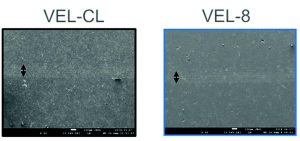

Acoustic emission bending test

Using a 4-point bending setup combined with acoustic sensor, VEL-8 showed superior crack resistance and propagation, while VEL-CL exhibited multiple visible cracks under the same stress levels (Figure 5).

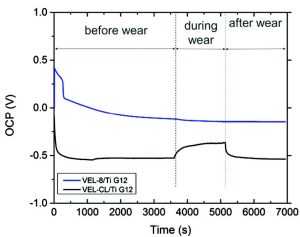

Tribo-corrosion behaviour in sulfuric acid leaching environment

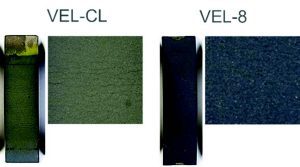

This test evaluates the synergistic interaction between wear and corrosion under sulfuric acid (H2SO4) leaching conditions. By combining mechanical abrasion with electrochemical attack, it replicates the dual degradation mechanisms typical in HPAL environments. Open circuit potential (OCP) monitoring and post-test wear track analysis were used to assess coating performance. VEL-8 demonstrated superior protection efficiency, maintaining greater electrochemical stability and reduced wear compared to VEL-CL (Figure 6), confirming its enhanced resistance to the coupled effects of tribological and corrosive mechanisms.

VEL-8 field trial performance in HPAL and POx operations

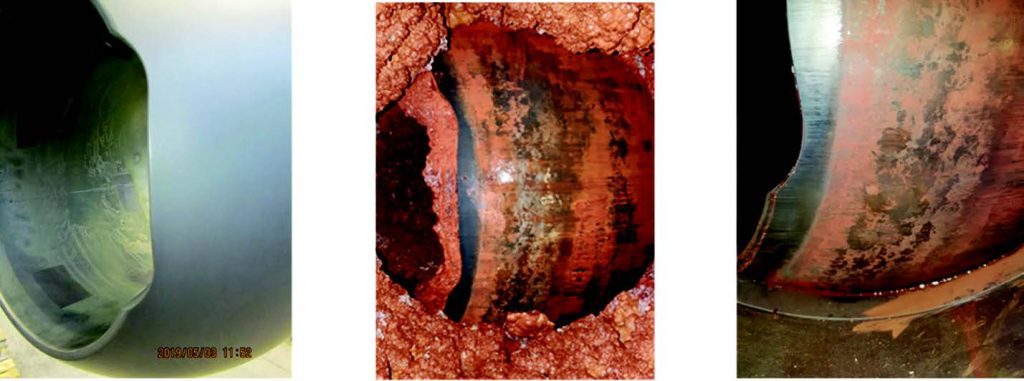

HPAL trial – Isolation ball valve

An NPS 14 Class 600 valve equipped with VEL-8-coated trim was installed at a major HPAL facility, initially in the inboard discharge, one of the most severe locations in the circuit. After 8 months of continuous service, the valve was removed and cleaned for inspection. The VEL-8 coating showed no signs of degradation, cracking or spallation. The valve was subsequently reinstalled at the outboard discharge, another highly aggressive location, for an additional 6 months. This brought the total service duration to 14 months across two of the harshest areas in the HPAL plant (Figures 7 and 8). This result doubles the service life of existing coatings, as shown in Table 1, providing a compelling case for VEL-8’s reliability.

POx trial – Autoclave agitator blades

VEL-8 was also trialled on autoclave agitator blades at a POx gold mining site an application with aggressive slurry exposure and oxidative chemistry. The blades were rit-blasted, coated and returned to service. The trial confirmed that VEL-8 provided satisfactory performance in this demanding application and supports its suitability for broader use beyond valve components (Figure 10).

Full-scale implementation of VEL-8

Following successful trials, VEL-8 has been industrialised and deployed at scale across HPAL and POx operations. Figures 11 and 12 illustrated two representative cases:

- An NPS 10 ball valve installed in a slurry feedline has performed reliably since commissioning (Figure 11).

- An NPS 14 slurry discharge ball valve has operated continuously for 24 months in a location historically prone to early coating failure (Figure 12).

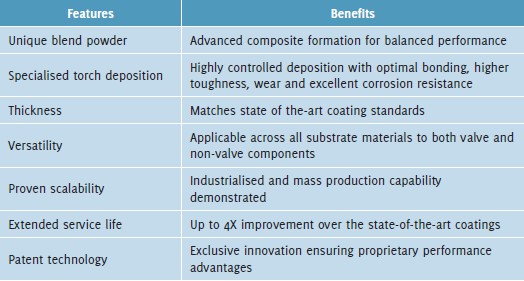

These results confirm VEL-8’s exceptional performance, marking a significant advancement in the reliability and longevity of coated components operating in the most demanding hydrometallurgical environments. In addition to its superior durability, VEL-8 contributes to a notable reduction in total cost of ownership by minimising both scheduled maintenance shutdowns and unplanned interventions. This breakthrough translates into greater equipment uptime, improved process continuity and measurable economic value for operators managing severe service conditions. Table 3 captures the essential attributes that differentiate VEL-8 from conventional coatings and supports its demonstrated reliability in both laboratory and field environments.

Table 3: Key features and performance benefits of the VEL-8 coating.

Conclusion

VEL-8 represents a significant step forward in protective coatings for hydrometallurgical valves and components. Engineered

to overcome the limitations of earlier-generation technologies, it combines:

- Outstanding corrosion resistance

- Superior wear performance

- High resistance to crack propagation

- Consistent field reliability

By extending service life in critical HPAL and POx locations, VEL-8 reduces unplanned downtime, improves asset utilisation and delivers measurable economic benefits to plant operators. As hydrometallurgy processes evolve and become more demanding, advanced coatings like VEL- 8 will play an increasingly central role in ensuring uptime, safety and cost-efficiency across the global mining and metals industry.

About the authors

Fadila Khelfaoui is a Corporate Engineer at Velan with 27 years of experience in metallurgy and materials engineering, specialising in coatings and surface engineering. She has led high-profile projects that bridge R&D and engineering, driving innovative material solutions from concept to field application in demanding industrial environments. Fadila is a licensed Metallurgical Engineer in Quebec and holds a PhD in Material Science & Engineering.

Fadila Khelfaoui is a Corporate Engineer at Velan with 27 years of experience in metallurgy and materials engineering, specialising in coatings and surface engineering. She has led high-profile projects that bridge R&D and engineering, driving innovative material solutions from concept to field application in demanding industrial environments. Fadila is a licensed Metallurgical Engineer in Quebec and holds a PhD in Material Science & Engineering.

Luc Vernhes joined Velan in 2003 and has held multiple positions over the years. He is now Director, Business Development. He holds a PhD in Engineering Physics and is a Mechanical Engineer.

Luc Vernhes joined Velan in 2003 and has held multiple positions over the years. He is now Director, Business Development. He holds a PhD in Engineering Physics and is a Mechanical Engineer.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, September 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”