IMI has celebrated a major milestone as its EroSolve Wet Steam solution surpasses 750 orders from power and process plants worldwide, demonstrating the tangible engineering benefits delivered by IMI’s Growth Hub innovation engine.

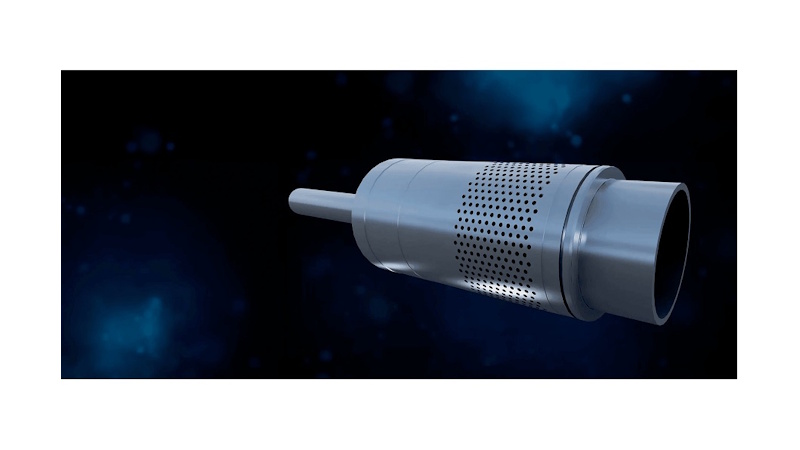

The EroSolve Wet Steam solution is designed to protect turbine by-pass valve internals from condensate erosion, particularly during plant start-up. By optimizing droplet impingement angles and using erosion-resistant materials, the solution enhances valve performance and extends the lifespan of valve trim components.

This technology has been successfully deployed across various power and process plants, delivering improved efficiency and reduced operational costs. Wet steam, typically formed during start-up due to insufficient drains, improper pre-warming, or incorrect operational logic, can be challenging to manage without major system modifications.

IMI’s valve trim upgrade offers a novel solution, allowing plants to operate efficiently without redesigning or upgrading entire systems. Left unmanaged, wet steam can erode critical valve components, creating safety risks, operational inefficiencies, and costly unplanned downtime.