Intoco’s Steel Division team, the people behind its outstanding service and commitment to customers.

As a highly respected steel distribution organisation, the team at – INTOCO – specialises in supplying high-quality prime bar materials from its UK headquarters. Over the past fifty years, countless clients have relied on the company’s high level of service and uncompromising quality to source speciality steels, including many valve manufacturers. Valve World met with Tony Preece, Managing Director, to learn more.

By Joanne McIntyre, Valve World

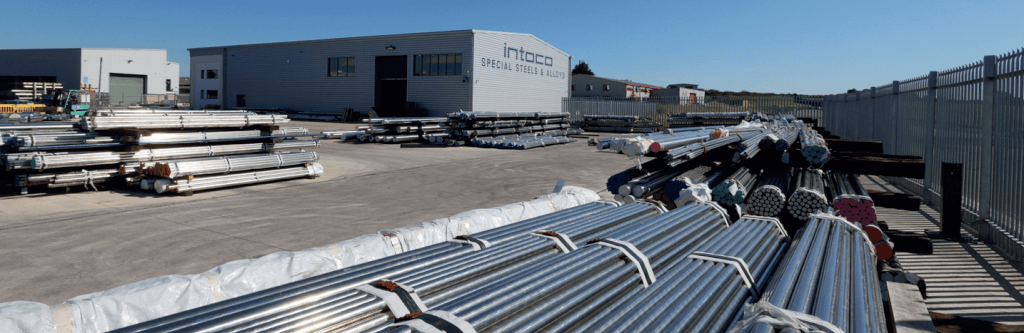

From its headquarters in Cheltenham, UK, INTOCO ships specialist steels and alloys around the globe. Managing Director Tony Preece explained that the company’s specialised shipping department ensures products are delivered fast and in perfect condition, protected in top-quality packaging. “We work closely with our customers to meet their needs. For instance, our products reach customers in mainland Europe within short lead times, a testament to the unwavering dedication of our logistics team.”

Specialised valve materials

As one of the largest independent stockists and distributors of specialised materials in the UK, INTOCO prides itself on providing consistently reliable and rapid service to its valued customers, having fourteen saws with the capability of working ‘lights out’. Catering to industries that require the utmost quality and dependability, such as oil and gas, INTOCO supplies high-end alloys designed for the most demanding applications and releases material with full certification to OEM specifications.

Valve manufacturers continue to rely on proven, corrosion-resistant, and high-strength alloys that meet the demanding requirements of their applications, and INTOCO supplies a comprehensive range of the high-performance materials commonly used. These include Alloy 718, Alloy 625, Super Duplex F55 (1.4501), and Duplex F51 (1.4462) – all available with full 3.1 or 3.2 certification in accordance with EN 10204 standards. Its materials are sourced from well-established European and international mills, ensuring consistent quality and traceability.

Strict quality control

Materials used in valve manufacturing are subject to extremely demanding conditions. They must perform reliably in corrosive environments, endure sub-zero operating temperatures, and meet stringent requirements for pressure containment. Material integrity is critical, and selecting the correct grade with the appropriate mechanical and chemical properties is essential to long-term performance.

With its strong focus on customer service, the INTOCO team provides full certification and is prepared to go the extra mile for its valve manufacturer clients.

“We supply material fully certified and in line with customer specifications, often for high-integrity and project-critical components,” explains Tony. “Where needed, our in-house technical team provides a specification review service to confirm material suitability, ensuring it aligns with the application requirements and relevant industry standards. We also pride ourselves on offering a cut-to-size service, helping reduce waste and machining time for our clients. Combined with our very competitive pricing and fast delivery capabilities, we provide a flexible and responsive service that supports the demanding schedules of valve manufacturers.”

Added-value services

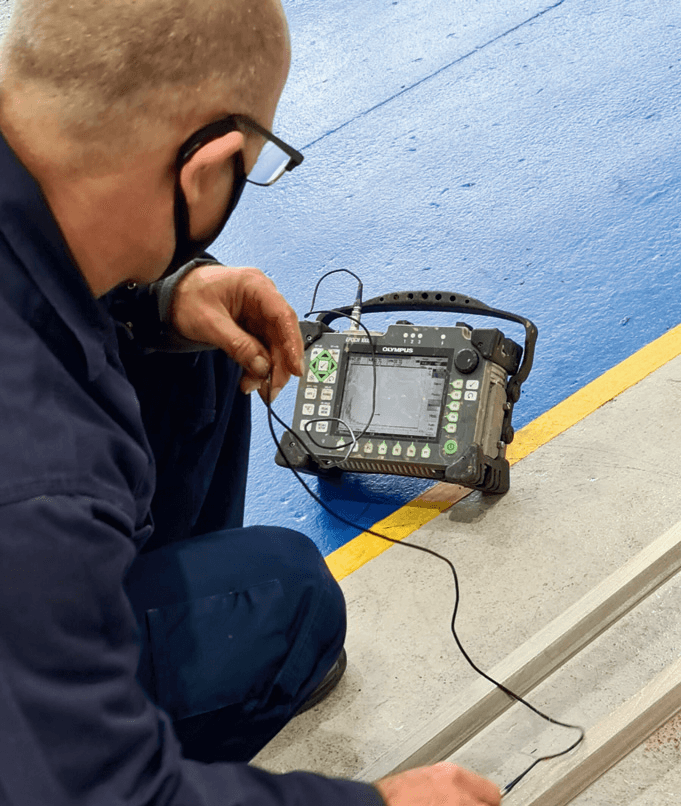

The INTOCO team has the skills in-house to provide added-value services to valve manufacturers. In addition to its technical and specification review, the company also offers a range of value-added testing services, including:

- Ultrasonic Testing (UT),

- Mechanical, chemical, and metallurgical testing,

- More extensive testing if required carried out by ISO 17025-approved Laboratories.

It also performs in-house Positive Material Identification (PMI) using Xray technology, providing instant verification of chemical composition and full traceability of materials.

Extensive stock of alloys

With over fifty years of experience, INTOCO’s efficient operations and well-organised factories reflect a deep commitment to quality control and customer satisfaction, ensuring every process meets the highest standards. The stainless steels and nickel alloys it supplies range in size from 6.4mm to 710mm in diameter. Tony emphasises that the cornerstone of INTOCO’s ongoing success is its very high stocking levels. “Our motto is: ‘If you don’t have it, you can’t sell it,’ and this has stood us in good stead over the decades,” he explains. “Our warehouses are fully stocked with around GBP 15 million worth of stock, translating to around 4,000 tonnes of specialist alloys.” As each order is processed, replacement stock is ordered immediately. INTOCO’s ongoing orders with steel mills, with lead times of up to a year, account for an extra 30% of stock incoming at any time.

“While markets may fluctuate, our customers know they can trust us to deliver what they need, when they need it.”

Tailored to the valve industry

While INTOCO supplies materials to a wide range of industries, it is well-versed in catering to the specific technical demands of the valve sector.

Valve manufacturing frequently requires materials that can withstand high-stress and safety-critical environments. Specific demands may include:

- Transverse Charpy testing at the material centreline

- Advanced UT inspection, such as angle beam or shear wave techniques

- 3.2 certification, often with intent-upgraded material for third-party approval

“Meeting these requirements consistently is key to maintaining quality and compliance across the sector,” Tony emphasises.

Intoco Duplex Steels & Nickel Alloys

| Stainless | |

| F51 – 1.4462 DUPLEX STEEL | INTEGREX NIT 50A NIT HS |

| F53 – 1.4410 SUPER DUPLEX STEEL | INTEGREX NIT 60 A |

| F55 – 1.4501 SUPER DUPLEX | 316L 1.440/1 DIAMETER 510 – 764 |

| 17-4PH – 1.4542 | 904L – 1.4539 |

| F44 – 1.4547 | 440C- 1.4125 |

| Nickel Alloys | |

| 718-API – 2.4668 | K500 – 2.4175 |

| 718-AMS – 2.4668 | C276 – 2.4819 |

| 625 – 2.4856 | A286/660 – 1.4980 |

| 400 – 2.4360 | |

| Hot Work Tool Steel | |

| W.2344 (H13) | W.2714 |

Extensive machining capabilities

Intoco’s vast in-house knowledge of machining – developed and refined through its manufacturing division, which exclusively serves the aluminium extrusion industry with press parts and tooling – has equipped the company with the capabilities and technical know-how to add significant value to raw materials. However, as Tony emphasises, Intoco is careful not to infringe on its customers’ operations: “We will never compete with them by producing finished products; our activities are limited to helping them save time and machining costs.”

Dive Deeper into Valve World

Enjoyed this featured article from our November 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

- Advanced industry insights

- Expert analysis and case studies

- Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”