As liquid cooling becomes the standard for high-density AI and HPC environments, GF launches a complete, reliable, and scalable polymer piping system for direct-to-chip liquid cooling to deliver stable, clean, and energy-efficient coolant flow between the coolant distribution unit (CDU) and the cold plate.

Direct-to-chip cooling places strict demands on the fluid handling infrastructure. Consistent flow, coolant purity, and hydraulic stability are critical to maintaining chip temperatures and system uptime. LiquidCore addresses these needs by combining high-performance polymer pipes, fittings, valves, actuation, instrumentation, engineered manifolds, jointing solutions, and precision design and pre-fabrication into one integrated solution.

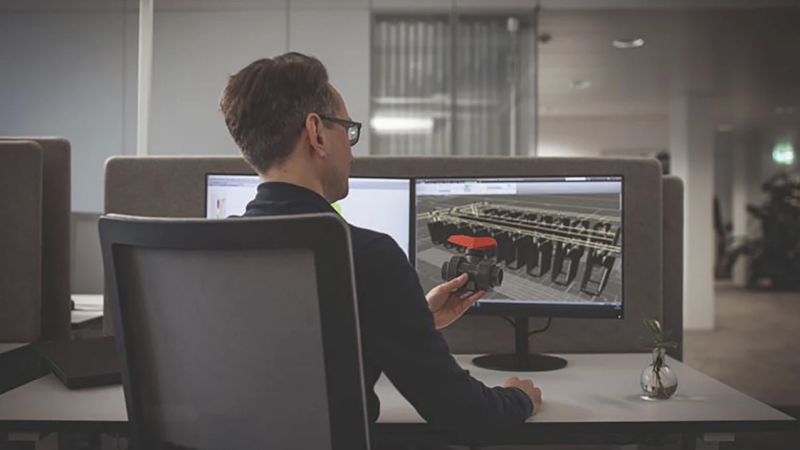

Distribution system: Pre-fabricated high-performance polymer liquid-to-rack piping system for reliable coolant distribution.

Rack integration: The patented Quick Connect Valve 700 has a 25% better flow rate, is more than 50% lighter than metal alternatives, and enables safe and fast rack integration.

In-rack manifold: Custom-designed manifolds ensure consistent coolant distribution across every port to maintain thermal stability under high computational loads.

Valve actuation and instrumentation: Valves, actuation, and measurement solutions support precise flow regulation and system efficiency.

GF’s global engineering and pre-fabrication services provide tailored 3D design, hydraulic and material reviews, reliable infrared jointing, and controlled-environment manufacturing to deliver ready-to-install modules. This combination reduces on-site labor, shortens installation times, and strengthens reliability for mission-critical cooling infrastructure. Weld bead inspection supports consistent joint integrity and long-term operational stability at the core.