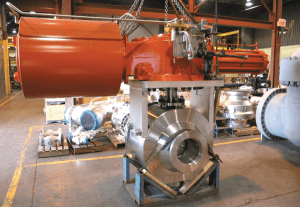

The impressive 78-inch Torqseal® triple-offset valve, the largest butterfly valve built at Velan.

Founded in Montreal, Quebec, Canada – where its corporate headquarters remain today – Velan has pushed the boundaries in innovation and technology to consistently meet its customer’s requirements. The company not only reflects on its insightful past but looks ahead to a bright future, consistently serving the global flow control industry.

Steve Fennell, Valve World Americas

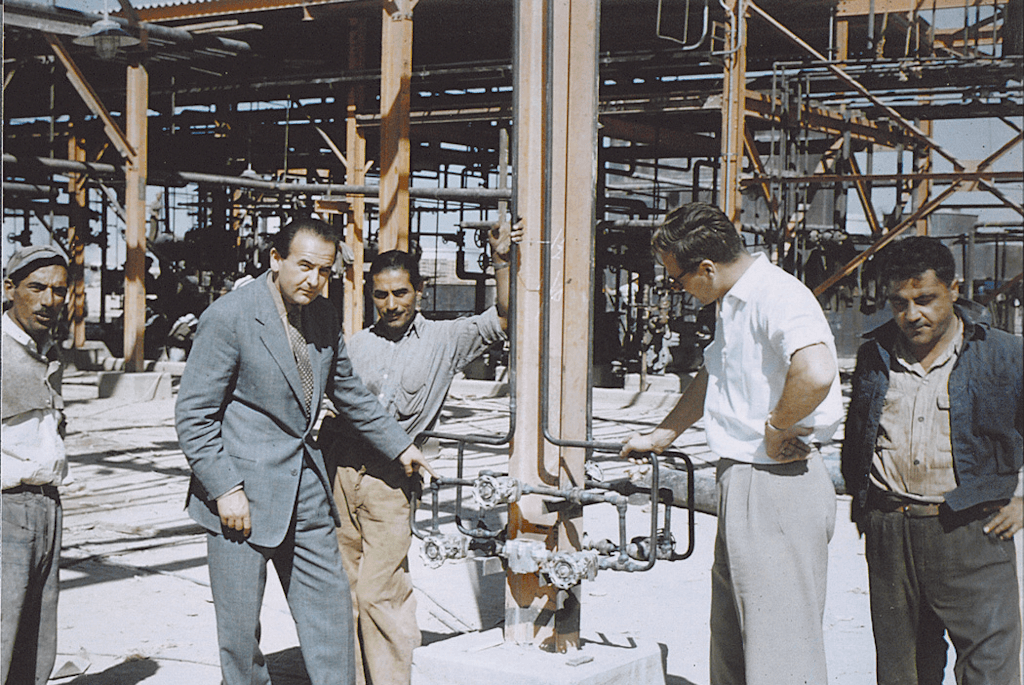

A.K. Velan approached innovation not as a trend but as a driving force behind progress. As the founder of Velan Engineering Ltd. in 1950, after immigrating to Montreal, Quebec, Canada, from Czechoslovakia, the entrepreneur quickly established the company’s footprint by engineering and manufacturing bimetallic steam traps. The technology became the first of several successful patents and achievements throughout the company’s seven-plus decades in the flow control industry.

As Velan celebrates its 75th anniversary this year, Valve World discussed the company’s storied past and current position in the global valve market with James Mannebach, Chair and CEO of Velan, and Daniel Velan, Chief Revenue Officer.

“A.K. cared deeply about offering the market the best products,” explained Velan. “His first invention, the bimetallic steam trap, offered a really novel approach to keep steam lines efficient. Velan looks quite different today than it did in those early years, but that ideal is still very much a part of our culture.”

His innovative and entrepreneurial spirit was a catalyst for the Montreal-based company to become a major player in the global piping and valve industry. Throughout the 1950s and mid-1960s, the company established strong business relationships with manufacturing facilities in the U.K. and Upstate New York, a second facility in Montreal, and a sales office in Germany.

Simultaneously, Velan Engineering Ltd. secured numerous contracts for its quality-tested steam traps, brand Piping King, and a series of valves through leading distributors in the U.K., parts of Europe, the Middle East, India, Singapore, and Japan. The company successfully established, and has since maintained, a strong presence in steam-related power generation applications, especially in the nuclear industry.

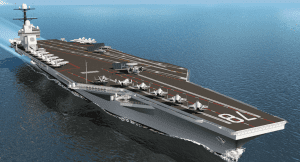

Notable nuclear projects were with the U.S. Navy, designing qualification-tested forged parallel slide gate valves for the USS Nimitz Class Aircraft Carriers. Velan also supplied cooling system valves for Ontario Power Generation’s Pickering Nuclear Generating Station, which was the largest nuclear generating station in the world when completed in the 1970s.

In 1970, they were the first valve manufacturer to achieve the ASME N Stamp. Over the following decades, they changed their name and branding to Velan Inc. and expanded their global presence. These entailed earning key industry certifications, including being the first North American valve manufacturer to earn ISO 9001 Standard in 1991, establishing advanced manufacturing facilities, and developing extensive international distribution networks.

Throughout this growth, two constants remained: a strong commitment to forward-thinking product growth, and the core principles that A.K. firmly rooted in the company’s DNA 75 years ago.

Velan’s plan for continued growth

Both Mannebach and Velan detailed the three core principles that drive the company’s success, and how they consistently deliver innovations within the flow control industry.

“The first is commitment to our customers,” said Mannebach. “However, it goes beyond the hollow words of ‘a customer always comes first.’ What’s interesting to Velan is when an opportunity arises that no other manufacturer has been able to solve. This allows us to bring application knowledge to our customers, and it’s these opportunities that drive the company forward.”

Mannebach explained that the second core principle is following the company’s innovative spirit. “It’s important to possess an innovative spirit and ‘connect the dots’ in new, creative ways for an application challenge so we can draw on our base of knowledge and craft products to meet a customer’s specific needs.”

The third principle is delivering the highest quality. Given the nature and complications of Velan’s applications in the nuclear, defense, and oil & gas industries, margins for error simply don’t exist. Velan ensures its products and solutions perform flawlessly through every stage of design, manufacturing, and testing, every time, under the harshest conditions.

“These three aspects are the cornerstones of the brand today,” said Mannebach. “The hallmark of the company is not only innovation, but the relevance of the innovation. We want to understand the demand in the marketplace and then bring the product to the market to meet that demand, not what we think it will be good for. This ideology all started 75 years ago when A.K. founded the company.”

New innovations & strong industry presence

Velan continues to drive innovation, expand its global presence, and actively support its core operations across the upstream and midstream sectors. Velan emphasized that the company is currently “doubling down” by further strengthening its market position by aligning its products with customer needs and meeting current (and future) demands through its diverse product portfolio.

For instance, the company maintains a strong focus on its high-temperature, high-pressure multi-turn valve product range, supporting existing and new projects worldwide. Additional emphasis is on its complete range of severe service metal-seated ball valves for delayed coking, ebullated bed, and other types of residue upgrading applications.

One example is the addition of the J-Series metal-seated double ball valve to the Securaseal® product line. Based on Velan’s certified and field-proven Securaseal® R-Series single-ball valve, the company recently introduced the J-Series as a single- or double-actuated bi-directional double-ball valve with several advantages.

Among its key features is the ability to operate two balls simultaneously with a single actuator, saving space and enhancing efficiency, making it beneficial for applications such as hydrocracking and catalyst handling.

The J-Series is rated for ASME classes up to 2500. It was part of a recent valve package for one of the largest ebullated bed units in the world, located in Alberta, Canada, where Velan supplied a large batch of R-Series and J-Series valves in a recent overhaul.

“We’ve had a very good push into ebullated bed and other types of hydrocracking processes,” said Velan. “We have a complete range of metal seated ball valves as well as other product lines for severe service and a variety of applications.”

The company also sustains a presence in nuclear power applications. Mannebach explains it’s one of the “brighter spots in terms of this economy” and an industry where they continue to advance their products and technology.

In October 2025, Velan was awarded a CAD $20 million valve order from Ontario Power Generation’s Pickering Nuclear Generation Station, the very same facility for which they supplied the original valves under A.K.’s leadership approximately 40 years ago. The order includes supplying Emergency Cooling Injection (ECI) valves for three reactors currently undergoing refurbishment.

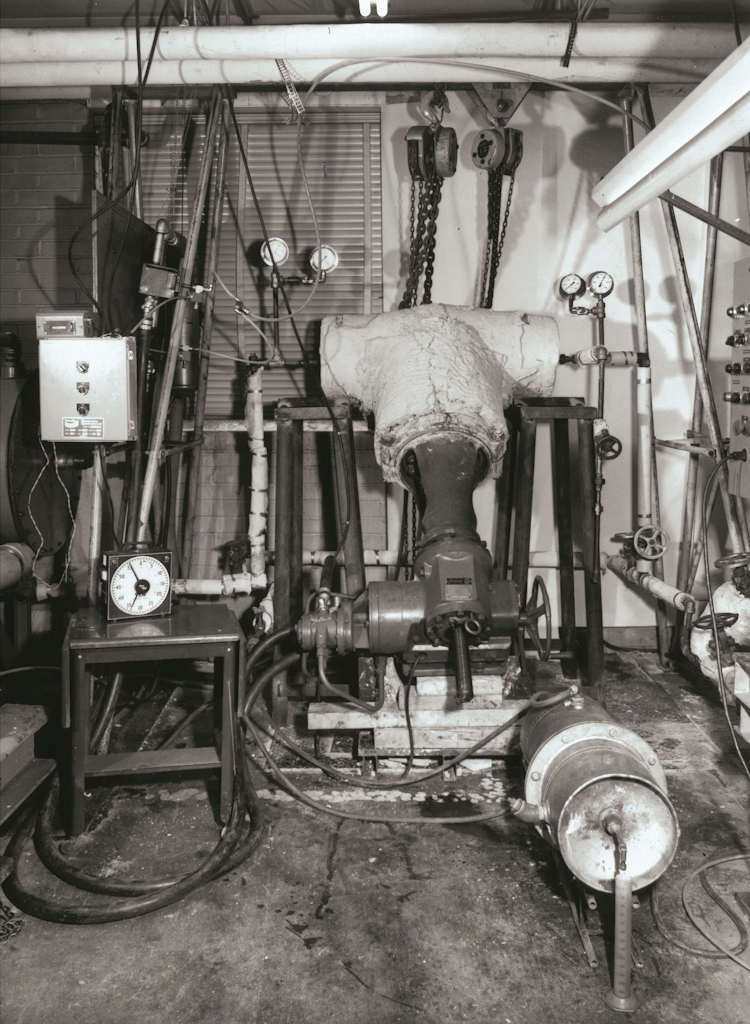

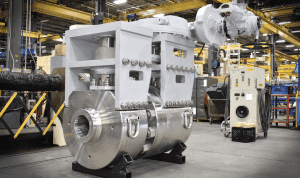

Earlier this year, Velan unveiled its 78-inch (NPS 78) Torqseal® Triple Offset Butterfly Valve, the largest launch by the company to date. The valve was built to ANSI/AWWA C207 Class B standards for a condenser water piping system shutoff valve.

The project was to replace a rubber-seated double-offset butterfly valve with the company’s advanced triple-offset design. As a result, the valve solved multiple performance issues for the end user.

“We continue to innovate,” said Mannebach. “This is a massive valve with a tight tolerance without leakage. Time and time again, operations meet and surpass our expectations with this kind of project.”

Fugitive emissions initiatives

As Velan’s past and present product portfolio has proven, the company stays attuned to relevant valve systems and designs across a variety of industries while adhering to strict standards, regulations, and compliance requirements. The company confronts fugitive emissions directly by delivering solutions that minimize impact and ensure compliance across many applications.

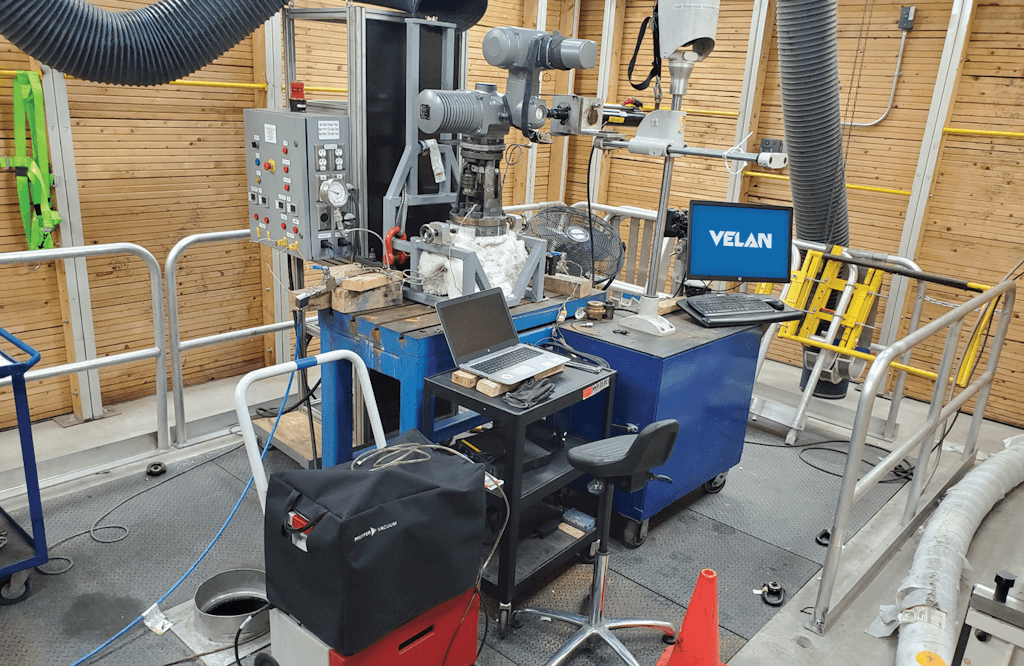

“We started our fugitive emissions research program over 40 years ago,” said Velan. “Our first emissions guarantee greatly exceeded industry standards, but we’ve seen industry and customer requirements become more stringent over time.”

Velan regularly updates its products to offer the best field performance. Recognizing that the primary cause of fugitive emissions is commonly through the valve packing seal, Velan introduced new Field Injection Ports (FIP) to the bonnet of API 602 Small Forged Gate and Globe valves. This practical improvement allowed for quicker and more cost-effective field repairs when needed. The “first-to-market solution and patent-pending FIP valve design” assists and reduces risks for end users if or when a leak is detected through the LDAR fugitive emissions compliance program. The valve’s pre-drilled and tapped bonnet minimizes the risk of drilling through the packing chamber while maintaining valve wall thickness code compliance, greatly improving in-line valve repairs.

“To our delight, this design has been included in several EPA consent decrees,” said Mannebach. “That these initiatives have caught the interest of groups like the EPA in the U.S., speaks volumes to the relevance of our technical innovation. This ties back to the foundational cornerstone of Velan by creating relevant technology, driving efficiency in operations, and responding to customer requirements.”

Both Velan and Mannebach emphasized that the company continually invests in developing high-performance valves and packing systems to prevent leaks and cross-contamination between media streams. The effort aligns with delivering the most reliable, efficient, and sustainable valve solutions on the market.

Velan’s dedication to complying with industry standards is reflected in the efforts of its highly qualified engineering team. They actively collaborate with API and ISO to develop and refine new standards that benefit the entire valve industry and end users. “This is the place that gets our engineers and team so focused on how we can have an impact while we continue to make solid investments and progress,” said Velan.

Dedication to digital advancements

Innovation within its product portfolio extends to Velan Digital Solutions, which clearly exemplifies the company’s commitment to digital innovations. Velan has continuously evolved with technology and digital monitoring capabilities.

“We have been offering monitoring solutions for automated valve packages since the 1980s,” says Velan. “Today, we also have a solution to monitor manual valves remotely.”

One of the many innovative launches is the V-Flange, an advanced and reliable remote monitoring system designed specifically for quarter-turn valves. It combines a robust on-valve device with an intuitive cloud dashboard, offering comprehensive monitoring without an external power supply or an electrical connection for data transmission.

The advanced features and cloud integration ensure end-users have all the information needed to maintain optimal valve performance and extend lifecycle. The V-Flange also reduces the need for manned inspections and interventions.

Velan Digital Solutions continually supports its global customers by developing and upgrading its proprietary technologies. Through integrating software, hardware, valves, actuators, and torque and position transmitters, Velan provides its customers with many effective options.

For instance, as a complete suite, Velan Digital Solutions delivers accurate valve monitoring, precise analytics, preventative alerts, and turnaround planning. It can also be configured to align with the demands of specific industries and individual plants, ensuring accurate decision-making, reliability, and productivity.

Velan is actively participating in the API RP 559 IIoT Task Force, the first API standard for IIoT recommended practices in the oil and gas industry, which addresses cybersecurity and other critical aspects.

“Cybersecurity has been a high-profile topic for quite a while now,” said Velan. “It’s certainly an area where we have invested quite a lot of effort.”

Increased global presence and aftermarket service

Velan has a long-standing global presence. It was the first foreign valve company to establish operations in Korea and the company also expanded throughout Europe and Asia.

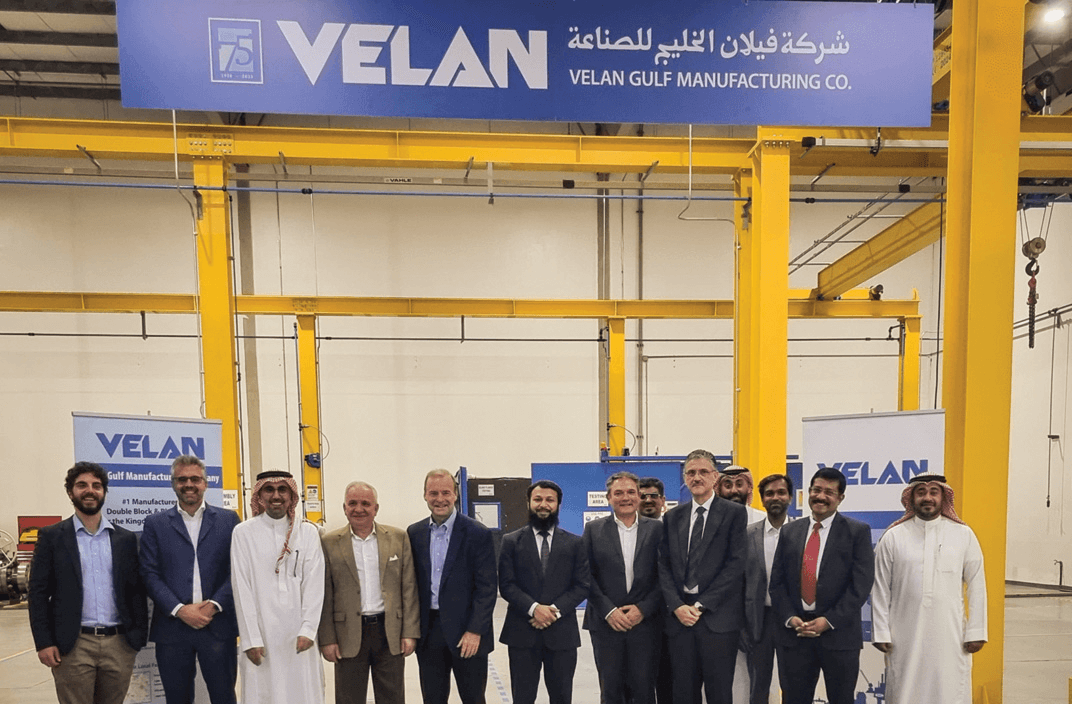

The company recently announced that its subsidiary, Velan Gulf Manufacturing Company, celebrated its first order assembled at the newly established production plant in Dammam, Saudi Arabia.

Velan Gulf is the first in-Kingdom manufacturer to receive 9COM approval for its Double Block and Bleed Ball Valves from energy giant Saudi Aramco in April 2025. This not only signifies additional growth for the company but also aligns with Saudi Vision 2023, which promotes industrial growth and sustainable development.

“Velan has been involved in the Middle East and the Kingdom for many years,” explained Mannebach. “This latest development in Dammam is an extension of our capabilities that are relevant to that market, as well as our commitment to be well-positioned around the world for our customers.”

Over 75 years of serving the flow control industry, Velan has remained a trusted partner in Canada, the United States, and around the world with many facets of its business, including aftermarket services. For Velan, reliability, ease of maintenance, and repair are just as essential as delivering a top-tier product.

“We have a very robust aftermarket service offering,” said Velan. “We’re always progressing on how we can better deliver our services to customers,” said Velan.

“When a valve is designed to be repaired in the field to prolong its life, it provides a much better outcome for everyone. So, we focus on that as much as possible. This is where our focus lies, as our goal is to help preserve the life and effectiveness of each valve for generations.”

More than 75 years after the dawn of Velan Engineering Inc.’s bimetallic steam trap, with decades of success in the flow control industry, Velan effectively progresses forward. It’s evident that the company will maintain its key position in the market with innovative valve designs, environmental efforts, and a strong global presence.

Dive Deeper into Valve World

Enjoyed this featured article from our December 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

- Advanced industry insights

- Expert analysis and case studies

- Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”