Pipeline pigging is vital for flow assurance and corrosion control but traditional trap systems are bulky, costly and risky. Wafer pig ball valves offer a compact, safer alternative, enabling frequent pigging in space-limited environments while cutting emissions and costs.

By Zahra Farrokhi, Atilla GÜVEN, Batu Valve Türkiye

Pipeline pigging is essential for maintaining flow and controlling internal corrosion, which accounts for about 60% of corrosion-related failures and 12% of recent pipeline incidents. Since 2000, routine pigging has reduced such events by nearly 79% by removing wax, water and debris, the key corrosion drivers (Short, 1992; Quarini & Shire, 2007). However, traditional pigging systems rely on large, costly trap stations that are often unfeasible in space-constrained environments like offshore platforms. These systems also present safety risks, such as accidental pig ejection during depressurization (Hopkins, 2012), which have historically limited pigging frequency and increased exposure to corrosion (Fowler & Al-Hajri, 2010).

Wafer pig ball valves offer a compact alternative by integrating pig launching and flow isolation in a single unit (Hartmann Valves, 2015). Their wafer-style monoblock design eliminates bulky barrels and mounts easily between flanges, dramatically reducing footprint and weight. This innovation has enabled pigging on previously inaccessible pipelines, improving safety, lowering emissions and cutting maintenance costs (Argus, 2023; Singh et al., 2022). This article reviews the valve’s design, materials and sealing systems, supported by cross-sector case studies and performance data from over 50 technical sources (Garcia & Martinez, 2025).

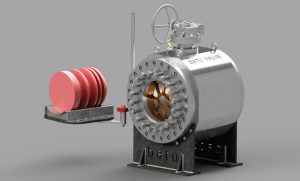

About Batu Valve Türkiye

Batu Valve Türkiye is a pioneer in pigging valve innovation, advancing wafer pig ball valve technology to modernise pipeline maintenance. Its compact monoblock designs integrate pig launching and isolation in a single unit, enabling safer, space-efficient operations while cutting emissions and lifecycle costs. With proven success across oil, gas, petrochemical and water transmission projects, Batu Valve continues to deliver engineering solutions that enhance pipeline integrity, efficiency and reliability.

Wafer pig ball valve design: Structure and operation

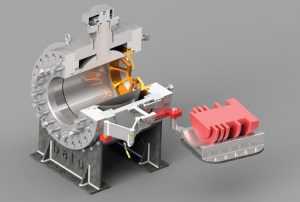

Unlike standard ball valves, pigging ball valves function both as isolation devices and pig launch/retrieval chambers (Hartmann Valves, 2015). They allow pig insertion and removal without needing to dismantle pipeline sections (Sim, 2021).

The wafer-type monoblock design eliminates bulky end flanges, using a single-piece body that mounts between flanges, significantly reducing dimensions, weight and leak paths (Hartmann Valves, 2015). Its full port bore closely matches the pipeline diameter, enabling smooth pig passage without obstruction or damage (Pigging Solutions, 2025; Quarini & Shire, 2007).

During pigging, the valve isolates the line, depressurises via vent valves, and allows pig insertion through a side-mounted quick-opening closure with interlocks for safety (Hartmann Valves, 2015; Argus, 2023). The same process applies for pig retrieval, removing the need for a separate pig trap.

These valves combine launching, receiving, and shut off in one unit, streamlining pipeline layouts (Argus, 2023). Models such as Hartmann’s allow bi-directional pigging and are designed per API 6D standards (Hartmann Valves, 2015).

A key feature is the absence of internal dead zones, preventing product entrapment, ideal for hygienic and batch-sensitive uses (HPS, 2023). This minimises residue and cleaning needs, especially in food, chemical or multi-product fuel lines.

Smooth internal geometry helps regulate pig speed and pressure gradients. CFD studies show that a uniform bore reduces turbulence and improves pigging safety and reliability (Zhang et al., 2020).

In summary, wafer pig ball valves are ideal for space-limited or modular systems. Their efficient design enhances pigging frequency and system integrity across demanding pipeline environments.

Design engineering, materials and sealing details

Designing pigging valves requires combining a full-bore flow path, integrated pig access and pressure containment in a compact structure. Manufacturers like Argus apply finite element analysis (FEA) to optimise monoblock bodies, reducing weight by up to 30% versus flanged valves, an important benefit in offshore platforms (Argus, 2023; Van Hardeveld & Smith, 2016; Emerson, 2017). Their gasket-free construction reduces leak risks and designs meet API 6D standards (API, 2021).

Materials are chosen for durability and corrosion resistance. Valve bodies are forged from carbon or alloy steels (ASTM A105, A350 LF2), often lined or overlaid with CRA materials like Inconel 625 for sour service (Abdullah et al., 2017; Velázquez et al., 2022). Balls are typically nickel-plated or stainless, engineered for strength and corrosion resistance.

Sealing systems are critical. Metal-to-metal seats are preferred for high-pressure lines due to their abrasion resistance (Hartmann Valves, 2015; Peng et al., 2021), with coatings like tungsten carbide or NiCr improving wear life (Cyrus, 2016). For lower-pressure or sanitary service, soft seats (PTFE, PEEK) may be recessed to avoid pig contact (Ivancu & Popescu, 2023).

Quick-opening closures with interlocks allow safe pig loading under depressurised conditions. These use O-rings or lip seals in elastomers such as NBR or FKM, protected from direct flow to extend lifespan (Hartmann Valves, 2015; Sim, 2021). Pigging valves vent up to 91% less gas than traditional traps during depressurisation (Argus, 2023; EPA, 2016), and some are designed to recover vented gas through flare systems (IEA, 2020).

To handle wear and pigging pressure surges, valves often include hard-faced seats (e.g., Stellite) and self-cleaning geometries that flush debris during actuation (Mokhatab & Mak, 2013). CFD and dynamic simulations confirm the need for impact-resistant internal structures (Borregales et al., 2014; Jaimes-Parilli et al., 2014). Modern designs include reinforced closures and filleted transitions for improved fatigue life (Mills & Langner, 2023).

Actuation is typically pneumatic or hydraulic, with fail-safe settings for remote operation (Morgan, 2021). Large-diameter valves are usually trunnion-mounted for reduced torque, and sealant injection ports allow emergency sealing (Hartmann Valves, 2015). Instrumentation like pig indicators and pressure sensors supports automation and safety (Chen et al., 2018).

Through precision-engineered structures and corrosion-resistant materials, wafer pigging valves meet the needs of modern, high-performance pipeline systems (Ivancu & Popescu, 2023).

Case studies and sector applications

Oil & Gas (upstream/transmission): Wafer pigging valves have transformed offshore operations where space and weight are limited. A 16” installation in the North Sea reduced the pigging system footprint by 60% and cut weight by over 50% (Garcia & Martinez, 2025). In other offshore manifolds, pig valves eliminated 17 tons of equipment (Emerson, 2017), helping avoid costly structural modifications and allowing more frequent pigging to control corrosion (Van Hardeveld & Smith, 2016).

Onshore pipelines: Argus deployed a 16” BALL VALVES pig valve system with a multi-pig launcher in North Dakota, enabling daily pigging and cutting methane emissions by 91% versus traditional traps (Argus, 2023; U.S. EPA, 2016). The system increased flow by 30% and reduced field crew visits. Similar improvements were reported by Sun Pipeline Solutions (2023) and Phillip (2024), with flow increases up to 24% and energy savings. Frequent pigging through compact valves led to over 40% corrosion rate reduction (Fowler & Al-Hajri, 2010; Sreckovic, 2014).

Safety & operations: Integrated pig valves streamline pigging to a single unit, reducing complexity and human error. Operators report faster, safer pigging without the projectile risk of horizontal traps (Morgan, 2021; Argus, 2023; Hopkins, 2012). Hartmann Valves (2015) noted their widespread adoption by leading oil companies. Petrochemical & refined products: Pigging reduces waste and improves batch recovery. HPS (2023) documented up to 99.5% recovery and 70% solvent reduction using pig valves. One fuel terminal saved nearly USD 1M/year by cutting interface losses 80% between fuel grades (Van Diep, 2019; Ruschau & Tiratsoo, 2006). Audits confirmed >2 tonnes of CO2 reduction per batch (Carbon-Zero, 2023).

Water transmission: In large pipelines, wafer pig valves improve flow and reduce energy demand. In South Africa, retrofitting pig valves boosted flow by 24% and saved nearly R1 million annually in pumping energy (Phillip, 2024). A US city restored 20% capacity and chlorine levels using inline pigging (Friedman, 2014). The valves installed without pipe modifications suit older systems well (Kirmeyer et al., 2002; Xie & Li, 2023).

Long-distance pipelines: Where pig traps are unfeasible mid-line, pig valves allow inline launching. Andeavor added valves to inspect segments untouched for decades (Singh et al., 2022). Multi-diameter lines were pigged using reducers and foam pigs (Pigtek, 2021). These compact solutions have made formerly unpiggable lines inspectable, improving integrity and reducing risk (Tiratsoo, 2003; Mills & Langner, 2023).

Performance summary:

- Flow efficiency: +20–30% (Phillip, 2024; Wang et al., 2008)

- Corrosion control: >40% improvement (Fowler & Al-Hajri, 2010)

- O&M savings: 30–50% labour reduction; ROI in 5 years (Sreckovic, 2014)

- Emissions: 91% methane cut per cycle (Argus, 2023); major waste reductions (HPS, 2023)

Wafer pigging valves are redefining best practices in pipeline maintenance. Their compact, low-emission and multi-functional design supports safer, more efficient systems and is being rapidly adopted across industries (American Petroleum Institute, 2021; Singh et al., 2022).

Lifecycle cost, environmental impact and overall benefits

While wafer pigging valves may have higher upfront costs, they offer significant lifecycle savings. Traditional pig trap systems, consisting of trap barrels, isolation valves, and auxiliary piping, can exceed $500,000 for a 16” setup. In comparison, pigging valves cost USD 150,000–200,000, cutting total capital and installation costs by up to 40% (Sreckovic, 2014). Maintenance is simpler and cheaper, with fewer components and seals requiring service (Sim, 2021). Faster pigging improves uptime, minimises blockages and extends pipeline life (Quarini & Shire, 2007). One South African utility reported nearly USD 1M in long-term savings due to efficiency gains from pigging (Phillip, 2024). In oil & gas, preventing just one failure, costing USD 10–50 million, can justify valve installation (Hopkins, 2012). Environmentally, pigging valves dramatically reduce emissions. Compared to conventional traps, they release up to 90% less methane per cycle (Argus, 2023) and support carbon credit reductions (Carbon-Zero, 2020). In chemical plants, they cut solvent use by 70% and recover over 98% of product (HPS, 2023). Pigging also lowers energy demand by reducing friction losses and pump loads (Xie & Li, 2023).

These valves simplify compliance with integrity management standards. Pigging enables more frequent inspection and cleaning, supporting PHMSA corrosion control requirements (PHMSA, 2018) and inline inspection flexibility (Singh et al., 2022).

Many models support automation through SCADA integration, reducing labour exposure and enabling remote pig launching, especially beneficial in high-risk environments like sour gas pipelines (Chen et al., 2018; Mills & Langner, 2023).

Modern wafer pigging valves offer a strategic, cost-effective solution aligned with operational reliability, safety, environmental goals and digital transformation. Their adoption is quickly becoming a best practice across high-integrity pipeline systems.

Table 1. Performance metrics of wafer pigging valves

| Metric | Improvement | Source |

| Footprint/Weight | 30–50% space, 50% weight reduction | Emerson (2017) |

| Flow Capacity | +20–30% after pigging | Sun Pipeline (2023); Phillip (2024) |

| Corrosion Incidents | ~79% fewer leaks with routine pigging | API (2014) |

| GHG Emissions | Up to 91% less methane released | Argus (2023) |

| Product Waste | 95–99% recovery in chemical pipelines | HPS (2023); Van Diep (2019) |

| Maintenance Costs | 20–40% O&M savings over 20 years | Sreckovic (2014) |

| Safety | Near elimination of pigging injuries | Argus (2023); Hopkins (2012) |

Conclusion

Wafer-style pigging ball valves mark a major advancement in pipeline maintenance by combining full-bore isolation and pigging functionality in a compact unit. Their monoblock wafer design enables installation in space-constrained areas, making pigging feasible where traditional traps are impractical (Garcia & Martinez, 2025). Built with advanced materials and engineered seals, they offer tight shutoff and corrosion resistance (Ivancu & Popescu, 2023; Peng et al., 2021).

Case studies from oil & gas, petrochemical and water sectors consistently show enhanced safety, pipeline hygiene and energy efficiency.

These valves remove long-standing obstacles to regular pigging, transforming maintenance from an infrequent, resource-heavy task into a routine process. As adoption grows, formerly unpiggable lines become maintainable, improving system reliability and longevity (Tiratsoo, 2003).

Their applications are expanding. In CO2 pipelines, pigging valves are now standard to mitigate hydrate risk (Mills & Langner, 2023). Hydrogen networks requiring frequent purging also benefit from piggable valve integration (Hartmann Valves, 2023). Advances include multi-pig launchers, larger diameters up to 48”, and bypass pigging technology to control pig velocity in gas lines (Zhang et al., 2020; Chen et al., 2017). Wafer pig valves simplify pipeline integrity programmess by supporting more frequent pigging and inspection. With regulatory support (API, 2021) and proven field success, they are fast becoming a new standard, paving the way for safer, smarter and more sustainable pipelines.

References available on request.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, September 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”