With the EU’s 2024 ban on hard chrome plating, the valve industry faces urgent change. This article explores the environmental, technical and compliance challenges of chrome plating, and how Expanite offers a cleaner, high-performance alternative without hazardous chemicals.

By Dr. rer. nat. Holger Selg and M.Sc. Zuzanna Stachlewska, Expanite

The main concerns about hard chrome plating

For decades, hard chrome plating has been the standard surface treatment in the valve industry, improving wear and galling resistance. However, hard chrome plating was officially banned by

the EU in 2024. The process involves the use of hazardous chemicals containing hexavalent chromium and requires post-processing like grinding and polishing. Hexavalent chromium is widely banned under the REACH regulation. The use of hexavalent chromium, a known carcinogen, creates significant environmental and health risks, while issues such as cracking, pitting and poor adhesion can compromise the functionality of the plated components. Under the RoHS (Restriction of Hazardous Substances) Directive, the use of hexavalent chromium is generally not compliant. Therefore, manufacturers now push for a cleaner, more sustainable alternative for hardening their parts without compromising performance.

Expanite®: An alternative to hard chrome plating

The patented Expanite technology is different to the electrochemical process of hard chrome plating as it is a gas-based process taking place in electric furnaces and what is more, it’s not a coating. Expanite does not use any hazardous materials or chemicals, thus, there is no outlet of any chemicals.

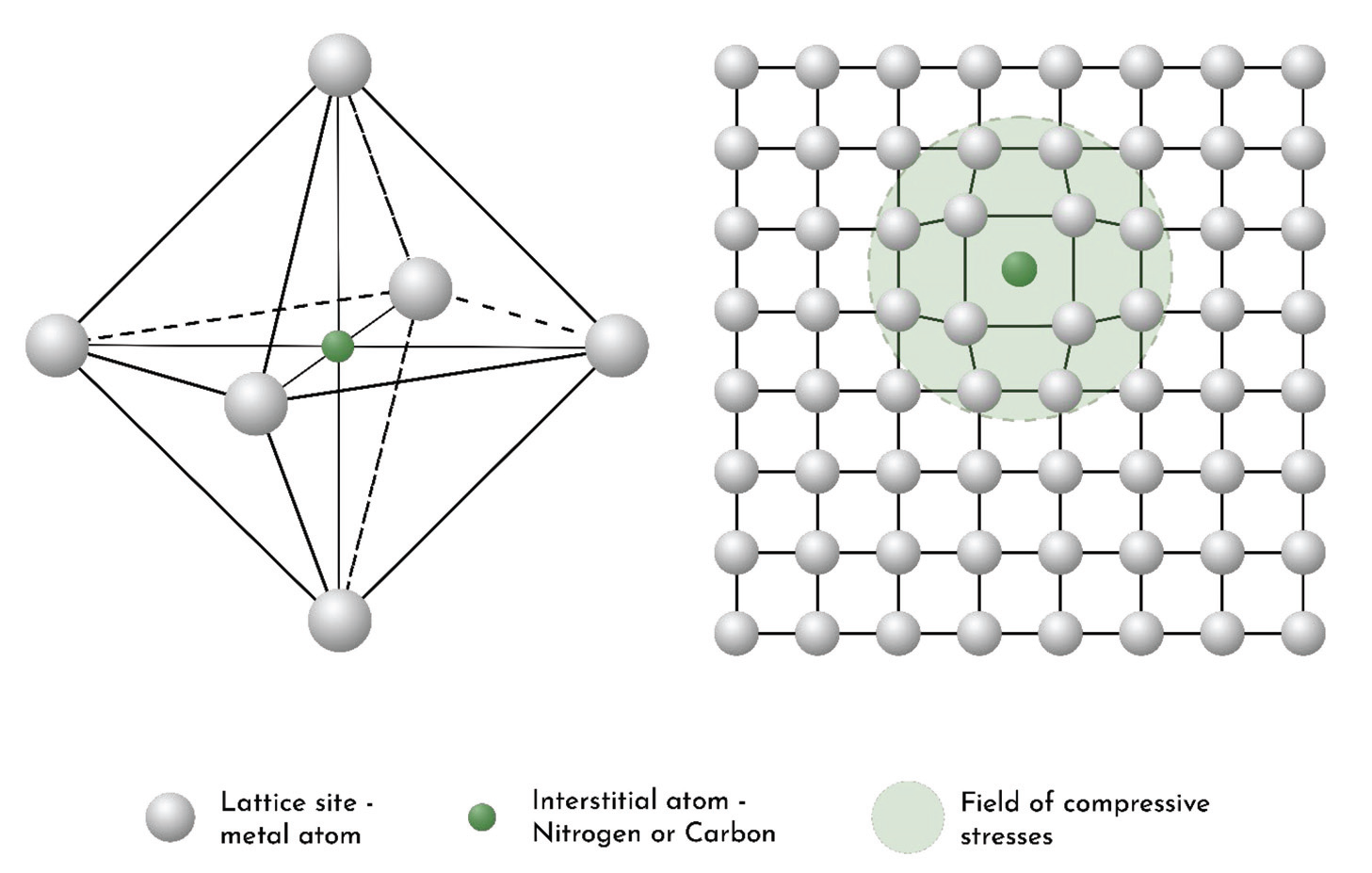

Expanite treatment is what specialists call a “thermo-chemical conversion”, or in simpler terms, a diffusion-based surface hardening process. The product which Expanite offers as a substitute for hard chrome plating on austenitic alloys consists of two process steps. The first step is ExpaniteHigh-T, a vacuum solution nitriding process that anneals the core material and provides limited increase in surface hardness, in relation to the core. The second step, ExpaniteLow-T creates a conversion layer of expanded austenite. No material is added or deposited on top of the surface of the parts, but rather a solid solution of interstitially dissolved large amounts of nitrogen, and carbon atoms are created thanks to precise control of process parameters. Those interstitial atoms occupy octahedral interstices of the crystal lattice and are responsible for inducing local strain fields, thereby generating compressive stresses in the affected region. As a result we see an increase in hardness of up to ten times, and with it, improved wear, galling and other mechanical properties.

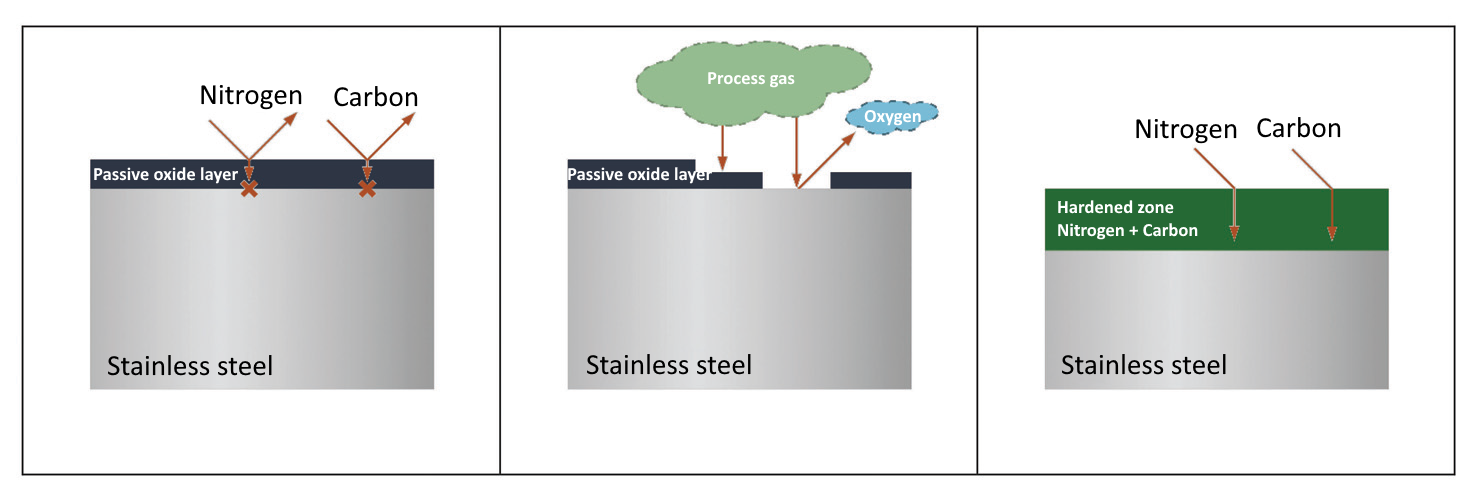

The SuperExpanite process does not require extensive pre-processing steps, which are traditionally used to remove the passive layer, prohibiting absorption of atoms from the process atmosphere. The passive oxide layer is a natural protection barrier on top of the surface of stainless steels and is impenetrable to atoms.

In the Expanite process, the passive oxide layer is reduced in-situ during treatment utilising the same process atmosphere. After processing, the surface is exposed to atmospheric air and

re-passivates, keeping the corrosion resistance properties of the material.

Due to Expanite being a gas-based process, the uniformity of coverage is not limited by complicated geometries. Moreover, the lack of post-process finishing, like grinding and polishing, makes the overall treatment significantly simpler and shorter, and the final geometry of products is more stable.

What Expanite achieves is a high hardness (up to 1300HV) on the surface, which is equivalent to, or even harder than hard chrome plating. The depth of the treatment varies and is dependent on final application, however, usual values lie within 10-30μm. Expanite is bringing protection to the component and extending the life of the component.

Technical aspects of moving away from hard chrome plating

There is a huge benefit of not using coating processes within the valves and other components because you avoid the delamination from the surface. There are many different chemical processes that do not allow hard chrome usage because of process media reacting with chrome in the coating. Common processes in the chemical industry containing any of these media would react with the chrome and dissolve the plating: hydrochloric (muriatic) acid, hydrofluoric acid, liquids with chloride salts, sulphuric acid (especially if heated), phosphoric acid and nitric acid (attacked slowly). Processes where the risk of the hard chrome layer peeling off and contaminating the media can become dangerous, such as in the fibre suspension, food, beverage and medical industries.

In standardised tests, Expanite treatment lowers the wear rate of the austenitic stainless steels over 100 times, as compared to the untreated material. This improvement can be attributed to the surface hardness increase of a factor of 5-10 depending on the base material (up to 1300HV0.05). The standard treatment depth of 20μm provides protection against wear even when hard third body particles are present. This increase in hardness is also responsible for significant improvement in resistance to adhesive wear. The risk of cold welding and of its dynamic form known as galling are mitigated beyond the yield strength of the austenitic stainless steels, which allows for smooth operations of valve components, even under high loads and after long periods without operation. One of the advantages of the Expanite treatment is the improvement of pitting corrosion resistance of austenitic components treated with SuperExpanite. Thanks to the nitrogen dissolved in the surface, the PREN number goes up, and with it, the breakdown potential, meaning that the surface stays passive beyond what is possible for the untreated material.

Applying Expanite

Ramén Valves made the switch to the Expanite technology for various reasons, including the environmental benefits, chemical composition and corrosion and wear resistance. Compared the hard chrome plating, Expanite has been able to offer a higher performance in terms of corrosion resistance and wear compared to hard chrome plating, as well as a better environmental impact as the company’s valves are now treated without the use of toxic chemicals.

About Ramén Valves

Ramén Valves is a Swedish manufacturer of industrial valves for the process industry, including pulp and paper, power generation, mining and chemical processing. With a focus on innovation, quality and sustainability, Ramén Valves has established itself as a trusted partner for its customers worldwide.

About Expanite

Since 2010, Expanite has been providing reliable heat treatment and surface hardening solutions for stainless steel, titanium, nickel-based and other specialty alloys. The Expanite solutions improve wear, galling and corrosion resistance, thereby extending the lifetime of critical components, minimising the need for virgin materials, and optimising value creation.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, October 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”