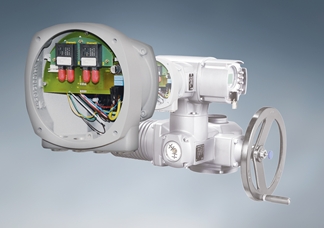

AUMA reports growth of fibre optics (FO) in process technology. Expanding demand for this field data transfer solution, has led to AUMA’s introduction of a single-mode FO interface capable of supporting automation solutions with a range of up to 15km between field devices. Confirmed FO benefits include transmission over large distances. Resistance to EMC ensures data and supply lines can be installed in one duct. Redundant data transmission is achieved by simple loop topology; galvanic isolation is integrated virtually and overvoltage damage is prevented. These advantages led AUMA to equip its actuators with integral FO fieldbus interfaces in the late 1990s.

Established multi-mode fibre optic technology supports distances up to 2.5km. Ongoing R&D from AUMA has led to introduction of a single-mode interface version which introduces a flexibility that caters for substantially greater distances between field devices. An enlarged actuator terminal compartment simplifies cable connection and the new FO solution can be configured as required.

A further confirmed benefit of fibre optic interfaces is evaluation of FO signal quality during operation. Should the optical signal fall short of its required level, an alarm is transmitted to the DCS via fieldbus.

FO cable checks are integrated into the comprehensive self-monitoring capability of AUMA’s new Generation .2 actuator controls. Signals are transmitted to the control room in compliance with AUMA or NAMUR classifications. Actuators can be specified with the new FO interface either in line or with star/loop topology.

Established multi-mode fibre optic technology supports distances up to 2.5km. Ongoing R&D from AUMA has led to introduction of a single-mode interface version which introduces a flexibility that caters for substantially greater distances between field devices. An enlarged actuator terminal compartment simplifies cable connection and the new FO solution can be configured as required.

A further confirmed benefit of fibre optic interfaces is evaluation of FO signal quality during operation. Should the optical signal fall short of its required level, an alarm is transmitted to the DCS via fieldbus.

FO cable checks are integrated into the comprehensive self-monitoring capability of AUMA’s new Generation .2 actuator controls. Signals are transmitted to the control room in compliance with AUMA or NAMUR classifications. Actuators can be specified with the new FO interface either in line or with star/loop topology.

Expanding demand for fibre optic technology leads to new AUMA interface