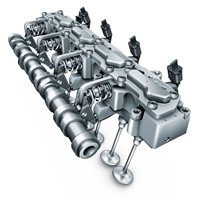

Schaeffler set a new technological standard for environmentally-friendly and dynamic engines in 2009 with the volume production of the world’s first fully-variable electrohydraulic valve control system, UniAir. Recently, the one millionth UniAir system was manufactured at the Schaeffler’s Cheraw, S.C. facility in North America.

The world’s first fully-variable electro-hydraulic valve control system is used in Alfa Romeo, Fiat, Chrysler and Jeep branded vehicles.

UniAir delivers the demand-based control of engine valves and allows almost any valve lift variation to be realized. The technology enables reductions in consumption and emissions as well as a significant improvement in torque curves. UniAir offers an extended range of options for matching engine operation to specific situations and requirements such as the implementation of modern combustion processes such as the Miller and Atkinson cycles. Cylinder deactivation is possible without additional engineering outlay. Thus, three-cylinder engines can be operated using rolling cylinder deactivation, meaning that each cylinder is switched off in turn. A key advantage of this is that the deactivated cylinder does not cool down so that optimum results can be achieved in terms of fuel efficiency and emission reduction. With a three-cylinder engine, this intelligent deactivation solution leads to fuel-saving, quasi “1.5-cylinder” operation.

UniAir delivers the demand-based control of engine valves and allows almost any valve lift variation to be realized. The technology enables reductions in consumption and emissions as well as a significant improvement in torque curves. UniAir offers an extended range of options for matching engine operation to specific situations and requirements such as the implementation of modern combustion processes such as the Miller and Atkinson cycles. Cylinder deactivation is possible without additional engineering outlay. Thus, three-cylinder engines can be operated using rolling cylinder deactivation, meaning that each cylinder is switched off in turn. A key advantage of this is that the deactivated cylinder does not cool down so that optimum results can be achieved in terms of fuel efficiency and emission reduction. With a three-cylinder engine, this intelligent deactivation solution leads to fuel-saving, quasi “1.5-cylinder” operation.