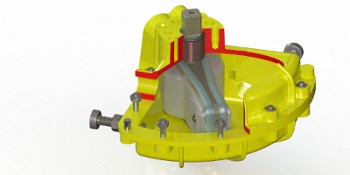

Rack and pinion and scotch yoke type pneumatic actuators depend on gears to transfer torque and movement, while integral vane-shaft actuators have no gears (or linkages). As a result, integral vane-shaft actuators are the hands-down choice for high cycle rate and modulating valve/damper actuation.

For pneumatic actuators with very low cycle rates, or ones that are not used for modulating service, internal gears may be acceptable. However, for applications where there are high cycle rates, or require accurate modulation, the use of a single machined vane actuator with integral shaft is preferred. The reason? No friction, wear, or backlash. 100 percent of the movement of the vane is transferred to the shaft without loss or hysteresis.