MAN Engines will be launching a maintenance-free valve train for industrial engines at the Agritechnica show. For this, the engine manufacturer is using a hydraulic valve lash adjuster, which makes regular checking and adjustment of the valve train unnecessary. Machine operators will benefit from the elimination of routine maintenance intervals and the resulting costs.

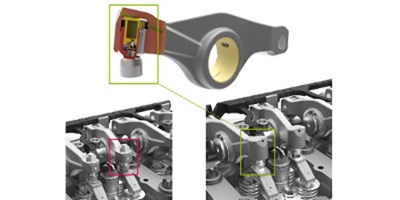

Balancing of the valve clearance, which is necessary due to thermally induced changes in length and wear of the components in the operating clearance of all industrial engines, is carried out automatically by means of a hydraulic element on the rocker arm. The hydraulic valve lash adjuster replaces adjusting screws with which the valve clearance was previously adjusted manually, and ensures that the valve timing corresponds to the optimum design timing of the engine.

The elimination of disassembly and maintenance work also brings further benefits: The transfer of deposits and dirt into the engine is prevented. In addition, space freed up above the cylinder head can be used more efficiently in many future applications. This increases machine manufacturers’ flexibility and options for motor integration into the application. This makes it possible, for example, to locate increasingly complex exhaust gas after-treatment systems close to the engine in order to comply with ever stricter emission limits.

The valve train is expected to be available from 2021 and will be installed in the D1556, D2676, D3876, and D4276 straight-six engines.