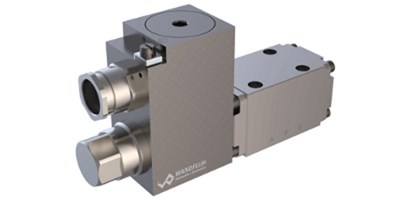

Wandfluh has extended the proven spool valves for the modular valve construction with execution for use in very corrosive environments. The valve is made of stainless materials and coated with high-quality surface protection.

It can continuously control volume flows up to 30 l/min with up to 350 bar and is available as a 2-way or 3-way function. The actuation is carried out via an integrated or external electronic system that regulates the solenoid current. The valve body and the cover are made from stainless steel (AISI 316L). The solenoid coil and the armature tube are very well protected against corrosion by their zinc-nickel coating (1000 h in salt spray test).

The valve of nominal size NG6 is controlled by a solenoid certified for use in explosion hazard areas. The valve with the designation WDBFA06_K9 can, therefore, be used in danger zones 1 + 2. The valve controls the direction of flow and thus the direction of movement or rotation of hydraulic actuators. The volume flow and thus the movement speed can be continuously adjusted by means of the proportional solenoid. The valve is mainly used in applications with continually changing weather conditions or in the vicinity of the sea.