Valves used in safety shutdown applications require actuators to perform reliably on demand. In a recorded webinar, Smart Electric Valve Actuators for Critical Fail-Safe Applications, Emerson’s Knut Riegel and Umberto Bianchi share how these actuators are well-suited for emergency shutdown (ESD) applications.

Knut provides background on ESD valves and their use and addresses the question on if ESD valve applications always require a fluid-powered actuator. After addressing this question, he shares how to move to the fail-safe position with an electric actuator and the working principle behind the Bettis RTS Series fail-safe electric actuators. He explains how these actuators can achieve the necessary safety integrity level (SIL) requirements for the safety instrumented function.

Umberto shares the main advantages in using the Biffi EFS electric quarter-turn, smart fail-safe actuators for opening and closing valves per the required safety demand.

ESD valves are always actuated and designed to stop the fluid flow in a fail-safe manner upon detection of a dangerous event. These valves are commonly found in hazardous applications in upstream, midstream, and downstream hydrocarbon-based processes as well as others with hazardous processes.

Fluid-powered actuators require compressed air or hydraulic fluid and require supply pressure, space dependent on the torque requirements of the ESD valve, and considerations for digital communication connections for preventive and predictive maintenance.

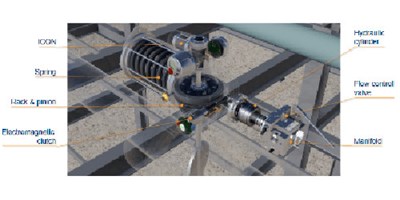

Knut shared 3 methods for moving ESD valves to fail-safe positions with electric actuators—supercapacitors, battery backup, and spring return.