The project presents not only pressure and temperature challenges, but holds enormous potential as well.

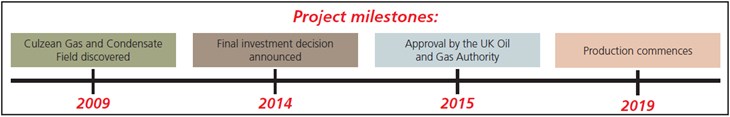

Located around 240 km off the coast of Aberdeen, the Culzean project is operated by Maersk Oil and its co-venturers, JX Nippon and BP (Britoil). The total combined investment in the development will amount to USD 4.5bn, with more than 50% committed to investments in the UK. Over the projected life of the field, it is anticipated that around USD 3.3bn in operating expenditure will be spent in the UK domestic market. To many in the industry, Culzean is a sign of the UK’s commitment to increased gas-fired electricity generation. It is expected to create 400 direct jobs and support a further 6000 more.

Culzean is classified as an ultra-high pressure high temperature (uHPHT) field. As such, it presents some challenges, but also some opportunities that have participants excited. It comprises lean gas accumulations in the Jurassic Pentland and Triassic Skaggerak sandstone formations that sit deep beneath other reservoirs in the North Sea. Katie Milroy, Geoscientist at the Exploration Division at Maersk explains that what makes the Culzean unique:

“You have two deep reservoirs sitting on top of one another – you’re not only 4.5km from the seabed but you’ve got reservoirs that are highly pressurised and at a very high temperature. It’s 350 degrees Celsius and 13,500 psi – the same pressures of an entire car resting on a nail.”

Such a challenging environment has implications for material selection.

“The pressure and temperature are the complicating factors, so materials have to be much stronger to cope with both extremes. We like to use simple tried and tested methods and make decisions that build in extra safety margins wherever we can” says Martin Urquhart, Culzean Project Director at Maersk. “Culzean is a huge project that needs comprehensive planning to gain the rewards. Our planning is coming down to the tiny little details – they may look unimportant now, but could end up as the crux of the matter and on the critical path.”

“Culzean is UK gas to the UK market, that’s how I’ve always thought about it” he says.

The project is characterised by three separate platforms: the wellhead platform (WHP), the central processing platform (CPF) with flare tower and separate living quarters and utility platform (ULQ) plus an FSO for storing condensate. In this way, the high pressure well and the area where staff are living and working is kept as far apart as possible. Further, all materials must be strong enough to withstand the extreme pressures and temperatures.

Capitalising on the lessons learnt

The Culzean project director Martin Urquhart is not new to such projects. He has worked on Total E&P UK’s Phase 2 West Franklin ultra-HPHT development, as well as a portfolio of Maersk Oil’s UK projects before taking on the Culzean role in May 2013. “We are fortunate enough to be at a point where the lessons learnt from over 20 years of HPHT developments are now clear and visible. The key element of Culzean is deploying proven technology – we can pull in best practice.” The challenges of the environment are addressed through the wells and facility designs, which reflect best practice from the HPHT sector, influencing decisions on equipment selection, platform and drilling location, and drilling trajectory.

The wells at the reservoir have a vertical path of over 15,000 feet which require care consideration. “Because of the dimensions of the wells, we are limited in the amount of wall thickness we can use to gain strength. So we need steels that are very strong.” says Wells Manager, Andrew Lough.

Valves and iPads

Maersk plan to use technology to capture data in accessible formats for better decision making. “The aim on Culzean is to tie everything together,” says Stuart McAuley, Culzean Engineering Manager. “One of the biggest challenges offshore today is that you spend a lot of time finding the right data. What we plan for Culzean is if something breaks or a valve needs replacing, you will have instant access to the data required whether you are on the worksite, office or the other side of the world.” Since equipment will be tagged and scanned it will allow manufacturing data as well as certificates, and even video simulation of maintenance to appear on a tablet.

This means that operators on platforms will not only carry screwdrivers, but also carry tablets as part of their toolkit as they perform maintenance and monitor checklists. Maersk anticipates benefiting from a 20% saving of people’s time once a fully connected platform is put into practice from 2019. “With the challenges in energy markets, using technology to improve our efficiency and bring sustainable cost savings is becoming ever more important. We estimate the digital toolkit can save more than USD 10m annually,” says Troels Albrechtsen, Vice President for Corporate Technology & Projects.

“The planning that is going into Culzean is building minimised costs into the whole project and new models of working that offer protection against wherever markets go next.”