Sinopec Corp. is China’s largest manufacturer and supplier of petroleum products and major petrochemical products. It is the second largest oil and gas producer in China. Its refining capacity and ethylene capacity are ranked 2nd and 4th globally. It purchases approximately 1 percent of all the high-performance valves ($360 million vs a world market of $36 billion/yr).

- Purchasers are moving toward global purchasing of valves

- Global purchasing opens the door for extensive evaluations of total cost of ownership

- The valve supplier perceived to offer the lowest total cost of ownership can generate higher sales margins and avoid competing on price.

The connect program brings together the valve suppliers and BHE by compiling much of the relevant information for decision making and providing the basis for total cost of ownership studies. For example, relative to valves for heat recovery steam generators, details on the valve problems at the plants such as stellite delamination and guidance documents such as approved bidders lists are included. Both the BHE personnel and the supplier connect personnel have access to papers such as one showing that repairable valves in high duty cycling are the lowest ownership cost option.

Daily discussions are possible with a LinkedIn group called HRSG Valve Decisions. McIlvaine has put together an 80-slide evaluation of HRSG valve problems and solutions. The LinkedIn additions will result in revisions to the evaluation and a series of webinars open to the BHE and Supplier connect people. Seven Alerts and newsletters also summarize the new developments. BHE is not planning to build any new coal fired plants but will be spending $20 million per year for valves for existing plants.

Four large coal fired units in Utah are planning air pollution control upgrades totaling $1 billion. Some of the 41 coal fired plants will be shut down but the remaining coal fired plants will be complying with new regulations’ regarding coal combustion residues and wastewater. In some cases ponds will be redesigned in others dry disposal methods will be utilized. New gas turbine plants will all be of the combined cycle design and will require valves for water intake, cooling, ultrapure water, and wastewater.

___

___

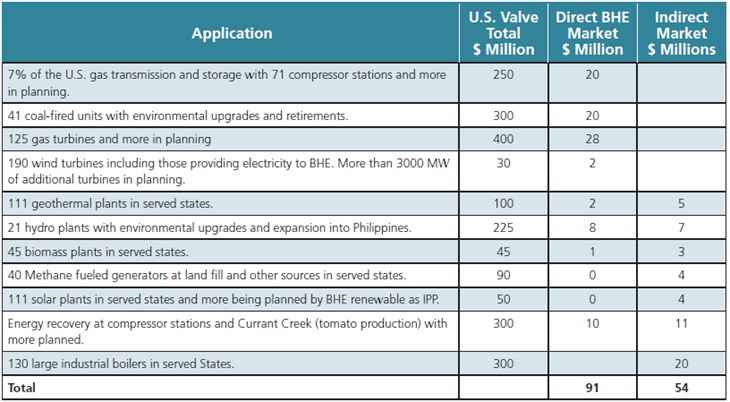

Valve Market Potential with Berkshire Hathaway Energy (annual market over next five years)

A number of valves including very large ones are used in hydropower projects. To prevent dam breaks or the uncontrolled overflow of the water dammed up, almost all of today’s dams are equipped with a bottom outlet. Its structure depends on the design capacity of the dam and is calculated based on the volume of the storage basin and its tributaries and discharge quantities. Valves are used to open, close and control the bottom outlet. The inlet pipe of turbines and large pumping stations are generally equipped with valves. As the inlet valve for the turbine, the function of a butterfly valve or equivalent is to control flow or isolate the unit for maintenance.

BHE has two large gas pipeline companies with storage and compressor stations. A large pipeline expansion is underway. When gas enters the compressor station with low pressure and velocity, it must be recompressed. Once past the inlet valve, such as a three-piece trunnion-mounted ball valve, the gas enters the compressor which is driven by turbines, electric motors, or engines which have additional check valve and other requirements.

Interstate pipelines include a great number of valves along their entire length. These valves work like gateways; they are usually open and allow natural gas to flow freely, but they can be used to stop gas flow along a certain section of pipe. There are many reasons why a pipeline may need to restrict gas flow in certain areas, including for emergency shutdown and maintenance. For example, if a section of pipe requires replacement or maintenance, valves on either end of that section of pipe can be closed to allow engineers and work crews safe access. These large valves can be placed every 5 to 20 miles along the pipeline. In geothermal plants the valves applied to control the steam coming from the boreholes drilled to the ground will come into contact with loosened soil from the ground that can contain silica, sand and other abrasives, which can cause numerous valve challenges including erosion and clogging.

___

___

Valves in this application need to deal with the solids while still being able to accurately control flow. After steam comes out of the ground valves become critical to the safe and efficient operation of the turbines. In this case, extreme measures must be taken to protect the turbine, pumps and people working in the area. Poor valve selection or maintenance could result in damages to turbine blades, superheater and reheater tubes or cause overheating in the pump.

Many of the valve applications are unique and require special knowledge related to one type of power generation. However, information about new developments such as hard coatings are applicable to a range of severe service applications. Other applications are identical independent of fuel type e.g. lubrication, hydraulic power, water intake. The same valve designs may be applied to the fuel gas for the gas turbine generator or for various compressor and storage applications.

This offers the opportunity for global specifying and possibly purchasing and inventory control. The interconnection of purchasing, engineering, operations and maintenance personnel at BHE with their supplier sales, engineering and development counterparts will be productive. This will specifically be the case when the end user needs to make a modification to a valve to fit his unique needs. Problems such as the cancellation of warranties can be more easily resolved with intercommunication and collaboration.