In an exclusive interview with Lead Plant Engineer Mr Charles Uleh from NLNG, we got to experience the daily life of an engineer at an LNG plant, the challenges that can be faced with maintenance, operation and lead times, and how to navigate the intricate world of valves and actuators in such a plant.

By Lyndsey Denton-Fray, Valve World

Career path

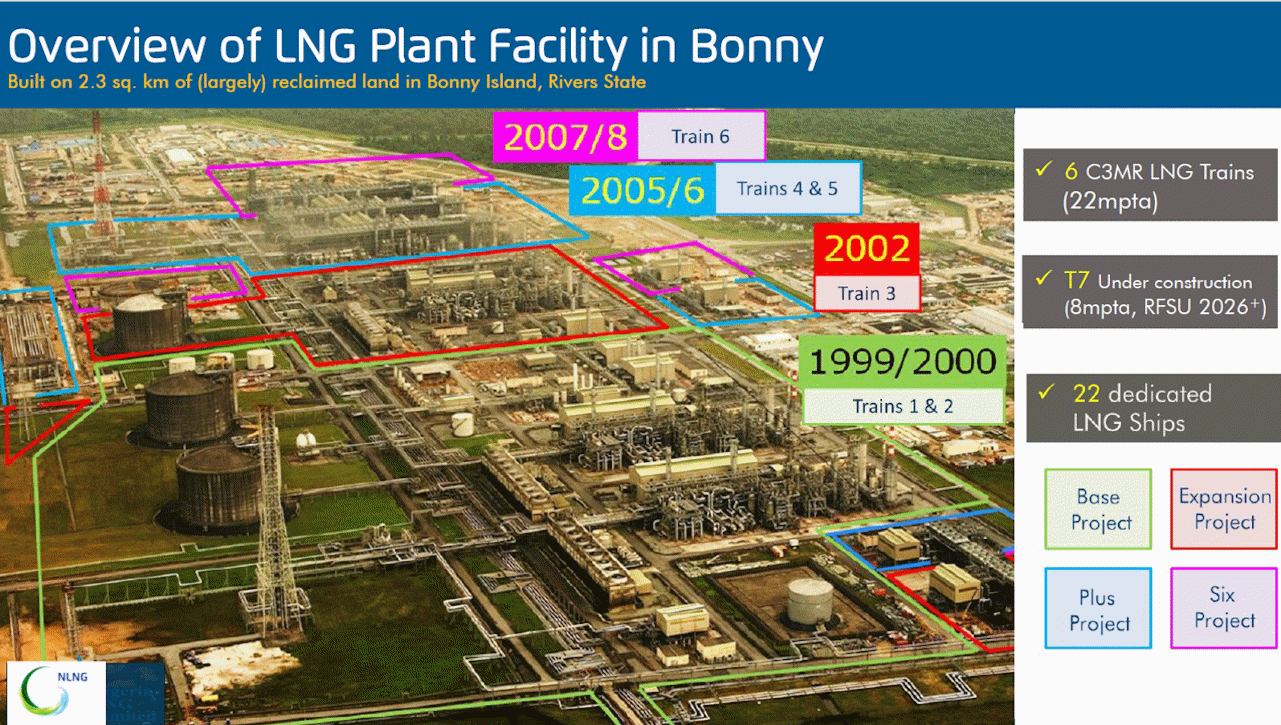

With over 27 years of experience, Mr Uleh’s insights into the dynamics of the Nigeria LNG (NLNG) are fascinating, having seen the evolution of the facility from its early days to its current status as a mature operation. Beginning his career as a telecoms engineer before progressing through the ranks at NLNG, he now leads what he calls the “Integrity Optimisation Team” that oversees trains one through six.

“In 1998, I moved to NLNG, where I started as an instrument technician, and over time, I grew through various roles, including workshop engineer, workshop supervisor and instrumentation discipline engineer,” explains Charles.

Over the years, his expertise in instrumentation has been pivotal in his progression to his current position as Lead Plant Engineer for the train assets, responsible for overseeing six operational trains. Charles manages a small team of discipline engineers (M/E/I) and plays a key role in keeping the plant operational. “The Integrity Optimisation team looks after the train assets, where my main focus is to ensure that everything that is required to keep the train running for the day is provided from an engineering perspective,” shares Charles.

A day in the life of a lead engineer

The role of a Lead Plant Engineer is dynamic and requires constant adaptability. On a typical day, Charles and his team ensure the smooth running of the plant through proactive technical monitoring and field assurance support. “The train can be very unpredictable, so your day is always busy,” he remarks.

“Whether it’s a small problem like a pump not starting or investigating material issues, there’s always something to handle. No day looks the same.”

While routine maintenance is part of the job, there are always unforeseen challenges, especially in a plant that has been operational for over 25 years. At 25 years old, the NLNG plant is entering what Charles describes as its ‘elderly’ phase. “Typically, a plant is designed for 20 to 25 years and is now at the end of its first cycle,” explains Charles. “The standard maintenance you will have applied when you’re starting is different now. You’re more in line of rejuvenation and then getting things back in order.” This means that keeping the plant in optimal condition requires ongoing re-engineering and problem-solving, especially in critical areas like flow control systems and valves.

Managing challenges

Perhaps most impressive is the sheer scale of the operation. The plant maintains approximately 10,000 valves across its integrated facility, with globe valves comprising over 80% of the inventory.

The plant works with a wide variety of systems, Charles shares: “We have a whole spectrum of valves here, and they’re all in deployment, whether it’s for the LNG trains or the utilities or gas receiving stations.” However, maintaining these valves over time presents challenges, particularly when dealing with the corrosion and erosion of materials in harsh conditions. As Charles explains, “After 25 years, the valves are starting to show signs of corrosion, especially on those in cold or hot services. We also have a lot of rain in Bonny, so pitting becomes a concern. These issues can lead to pinhole leaks, and ultimately, loss of containment if not identified and managed proactively.”

Despite these challenges, the plant is well engineered and equipped to manage the issues that arise. As Charles puts it, “We have strategies in place to respond to any situation. It’s not always in your hands, but with proper planning and a good team, we’re able to adapt and keep things running. We have the early warning system via Valve Predictive Analytics, Maintenance Advisor for valves with diagnostic capabilities. We have the ‘find and fix’ team that constantly scan for fugitive emissions from flange joints and are now deploying area scanning.”

Supply chain: the 18-month challenge

With so many valves in use, the need for reliable supply chains is critical. However, one of the most significant challenges facing the operation is the extended lead times for replacement parts following from the global disruption in the supply chain due to COVID-19, as well as the fact that the plant is situated on the remote Island of Bonny. “The lead-time for a simple part is about 18 months, average. So, we hold a significant amount of stock in our warehouse to ensure we don’t face disruptions. We practically need to have a whole train in the warehouse seated,” Charles explains.

Given the unpredictable nature of the LNG industry and the long wait for parts, the plant is exploring innovative solutions, including 3D printing. “We’ve started using 3D printing, but it’s still in the early stages. We’re not printing valves yet, but we’ve been able to replicate some components for pumps, which has been useful during turnarounds,” he shares.

“The confidence we gain from this will lead to greater adoption in the future.”

Sustainable thinking

As sustainability becomes an increasingly important consideration in the energy sector, the plant is taking steps to incorporate smarter technology into its operations. Charles elaborates:

“We’re deploying the Accelerated Asset Intervention Programme to minimise disruptions. We’re replacing components, but not just like for like—now we’re focused on adding technology that gives us diagnostics and predictive capabilities. If I were to buy a valve now or a positioner, it has to come smart, where it provides me with the needed diagnostics that I don’t have to go to the valve to know.”

This proactive approach helps the plant avoid unnecessary downtime and supports its sustainability efforts. “If I have a valve with a Low Friction alert, I know I need to check it immediately to ensure it doesn’t result in Loss of Primary Containment or cause environmental harm,” Charles adds.

The plant also focuses on sustainability through improved environmental packaging and selecting materials that minimise leakage risks. “We’re looking for environmental packing that ensures no leaks to the environment,” Charles explains. “This is an ongoing effort to align with global sustainability goals, and we have a whole team dedicated to ensuring we meet these objectives.”

Looking forward: Train 7 and beyond

Looking ahead, the plant is gearing up for the commissioning and startup phase of Train 7, a significant project that is 80% complete. The engineer describes the excitement surrounding this development: “Train 7 is coming along well, and we’re excited to participate in it. We’re also looking at Train 8 and beyond. It’s an exciting time for the team, and it’s a big step for us in increasing our market share.”

While the new trains will incorporate some of the latest technology, the plant will focus on maintaining consistency with existing infrastructure. “You want to avoid straying too far from what’s already in place,” he states. “Whilst we will incorporate new technologies where appropriate, we have to balance that with the total cost of ownership of the whole complex in terms of our inventory holding, the attendant issue with lead times and storage implications. Our advantage is also our existing technology, so we are not planning to stray far from this.”

One key takeaway from the conversation was the importance of strengthening relationships with suppliers to ensure smoother operations. “We’re actively working on building stronger relationships with our suppliers and exploring ways for them to hold stock for us in-country,” Charles states. “This would help reduce lead times and ensure that we have the parts we need when we need them. The goal is to create a more seamless supply chain to support our operation.”

Conclusion

As the Lead Plant Engineer at NLNG, Charles’ role involves overseeing complex systems and ensuring the plant remains operational despite the challenges of aging infrastructure, supply chain delays and environmental concerns. His insights into the ongoing efforts to improve efficiency, sustainability and technology adoption highlight the ever-evolving nature of LNG operations. With new projects like Train 7 on the horizon, the future looks promising for Nigeria LNG, and Charles remains focused on ensuring the plant’s continued success for years to come.

Dive Deeper into Valve World

Enjoyed this featured article from our May 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

- Advanced industry insights

- Expert analysis and case studies

- Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”