JIP33 is poised to provide the industry with efficient and minimalistic specifications that will make procurement much more efficient.

By Alexandra Kist, Valve World

At the Valve World Conference & Expo 2022, attendees were treated to Rachel Manley’s highly interesting presentation on digitalising standards and specifications. Valve World spoke with her to learn more about the project she is currently working on: JIP33.

Career overview

Fresh out of university with a BEng in Mechanical Engineering from Leicester University, Rachel worked as an Applications Engineer before moving into the oil & gas industry in 2001 as a Mechanical Requisitioning Engineer. She joined Aker Solutions in 2012 as a Project Engineer and began her work with JIP33 five years ago. As Project Manager for JIP33, Rachel manages the integrated Aker Solutions and IOGP team of project engineers and subject matter experts responsible for writing specifications. She is also responsible for managing the specification schedules, and technical writing services. Rachel oversees a team which includes project engineers, lead subject matter experts (SMEs), and various specialists.

What is JIP33?

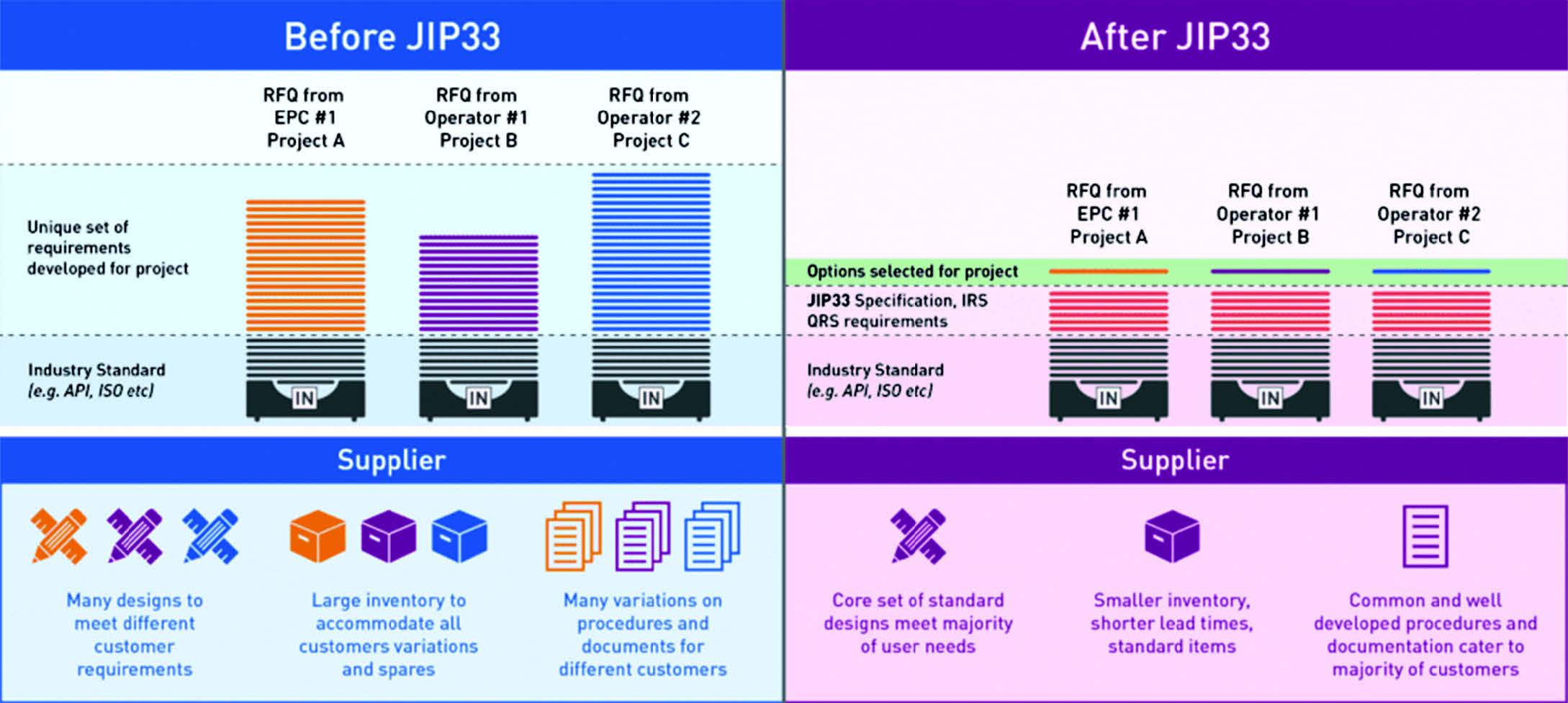

Joint Industry Programme 33 (JIP33) was initiated in 2016 by the IOGP (International Association of Oil & Gas Producers), with support from the World Economic Forum Capital Project Complexity initiative, to standardise the specifications used for procuring equipment to improve cost, lead times and quality. They aim to make specifications that define the essential minimum to purchase equipment. Traditionally, each oil and gas operator had its own specifications, of which each could be hundreds of pages long. Companies could also provide multiple sets of requirements – sometimes even within the same project. The IOGP concluded that the process was vastly inefficient and set forth to create a portfolio of universal specifications for procuring equipment to streamline and drive efficiency in the supply chain (Figure 1).

The specifications are developed and maintained in collaboration with twelve major operators who are members of IOGP. Aker Solutions provides project management services and SMEs to write the specifications. Every JIP33 specification that IOGP publishes is freely available worldwide; no membership is required.

Current status

So far, 54 specifications have been published and the team is currently working on about 20 different specifications, of which two-thirds are previously published specifications undergoing their first maintenance.

“All JIP33 specifications are intended to be overlays or supplements to an existing industry standard, we are not trying to write our own specifications, but rather support what’s already out there,” stresses Rachel. “When we develop a specification, it’s published by IOGP. When subsequently the parent standard is revised, we consider whether we need to revise our specification further, so it aligns with the new parent standard. We also consider any new learnings that are actually being put into practice.”

It is a careful process for operators to absorb the specifications into their own libraries. “Operators go through a process of implementation, working out how to include them in their libraries and apply them across projects.”

The scope of the new JIP33 specifications may not always exactly match the operators’ specifications. “They may want to further narrow down some of the options in the JIP33 specifications for their company use. Feedback from the operators on these company-specific changes to the JIP33 project team is key for understanding how the JIP33 specifications can be further improved in the future”.

So far, several specifications for valves and flow control equipment have been published. To date, they have published specifications for ball valves (API 6D), gate valves (API 600/603) and subsea pipeline valves (API 6DSS). They are currently in the process of updating the topside valve specifications.

“Under the instrumentation umbrella, we’ve also published specifications for actuators for on-off valves (ISO 12490), pressure relief valves (API 526), pressure regulators and control valves.” This year, the specification for actuators is expected to be updated and the pressure relief valves specification will undergo maintenance as soon as API 526 is re-published.

The process

JIP33 specifications are based on existing industry standards and provide all requirements necessary to purchase equipment and packages. Figure 2 shows the structure of JIP33 specifications, which consist of the following documents:

- A Supplementary Specification, written to be applied with a defined industry standard. A set of minimum requirements is specified, which are considered sufficient to purchase equipment that meets the functional needs of the users.

- An Information Requirements Specification (IRS) specifying a list of pre-defined documents/data required from the supplier.

- A Quality Requirements Specification(QRS) specifying the quality management system, and purchaser level of involvement in suppliers’ inspection and testing activities.

- An Equipment Data Sheet Template specifying the options the purchaser wishes to select and project-specific information.

Since JIP33’s inception, the team has developed a process for developing specifications. “There has been a huge learning curve: trying to develop the right process and updating it as we go along,” explains Rachel. “In 2019, we also embarked on a digital journey to write the specifications using an online cloud-based tool. That has improved the quality and traceability of our specifications.”

She also emphasises the skill required for technical writing. “We need to know how to question the people writing the specs to get what we need from them so they can write the requirements correctly. We have guidelines and industry standards to follow to standardise the way we write digital requirements, which is an expertise that we have developed.”

The digital tool has been in use since 2019. “We have collaborated with over a thousand representatives from suppliers, EPCs and operators. We have processed over 35,000 comments received during public reviews of the 50 specifications we have developed and maintained in that four-year period. That is what a digital tool can do for you,” Rachel explains. Reviews were previously done using spreadsheets and email, and were prone to human error and loss of data.

Suppliers are key to the success of JIP33. The team is always looking for ways to increase their engagement with suppliers, especially when trying to frame the topics to decide how the specifications will look. Suppliers are also invited to contribute to the public review of the draft specifications when the specification is about halfway ready for publication.

“We invite reviews and comments from suppliers, EPCs, the twelve member operators, any operators that want to be involved, consultancies, SDOs, etc. With valves, we are very fortunate to have a long list of manufacturers and stockists who are interested and engaged.”

Sourcing engineers

Since becoming the JIP33 Project Manager in 2022, Rachel has adapted to a less hands-on approach. “When I started on JIP33, there was just another Project Engineer and myself, and we grew organically with the project. He left at the same time as I took over as Project Manager, so I had to backfill both of our positions and knowledge. Suddenly, we had lost the experience of two Project Engineers while taking on less experienced staff, which was a challenge.”

Sourcing engineers is a difficult task, Rachel can attest, having dealt with not only recruiting Project Engineers but also Lead Subject Matter Experts. “When we produce a specification, we need a Lead SME who knows their subject inside-out and can also hold their own in a group of SMEs from twelve major operators.” She is referring to the operators who sponsor JIP33, including ExxonMobil, Saudi Aramco, Shell, and TotalEnergies. Those sponsors bring highly knowledgeable experts to the table, so the Lead Subject Matter Expert must be able to command their respect when they are producing the specification together. “They are essentially the scribe on behalf of the twelve operators, but they have got to make sense of what is discussed,” Rachel explains. “They need to be part of the discussion, even though they do not have a vote, because we are doing this on behalf of the oil & gas operators. It is not our (Aker Solution’s) specification.”

Expectations for JIP33’s future

JIP33 does not have a definite end date: it will come to a natural conclusion when no specifications are left to streamline. Occasionally, a specification never gets to publication. This is considered a success as well, as in a recent example, we handed a completed specification over to API to use as a basis for a new industry standard. “That is part of a perfect solution, because eventually, we would like to think that the JIP33 library of specifications disappears, and everything is absorbed into existing industry standards.” Another good alternative would be for standards development organisations to create new specifications or standards of their own based on JIP33 specifications, as with the example above.

About Aker Solutions

Aker Solutions delivers integrated solutions, products and services to the global energy industry. We enable low-carbon oil and gas production and develop renewable solutions to meet future energy needs. By combining innovative digital solutions and predictable project execution, we accelerate the transition to sustainable energy production.

About this Featured Story

This Featured Story is an article from our Valve World Magazine, March 2023 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”