In High-Pressure Acid Leaching (HPAL) and Pressure Oxidation (POX) applications, valve trim performance is critical to ensure reliable operation under extreme conditions. Traditional coatings often fail prematurely, leading to costly downtime and maintenance. This article introduces an advanced ball valve trim technology that significantly outperforms conventional coatings, offering superior wear and corrosion resistance for enhanced reliability and reduced operational costs.

By Evelyn Ng, Callidus Group

The critical need for high-performance valve trim in HPAL & POX

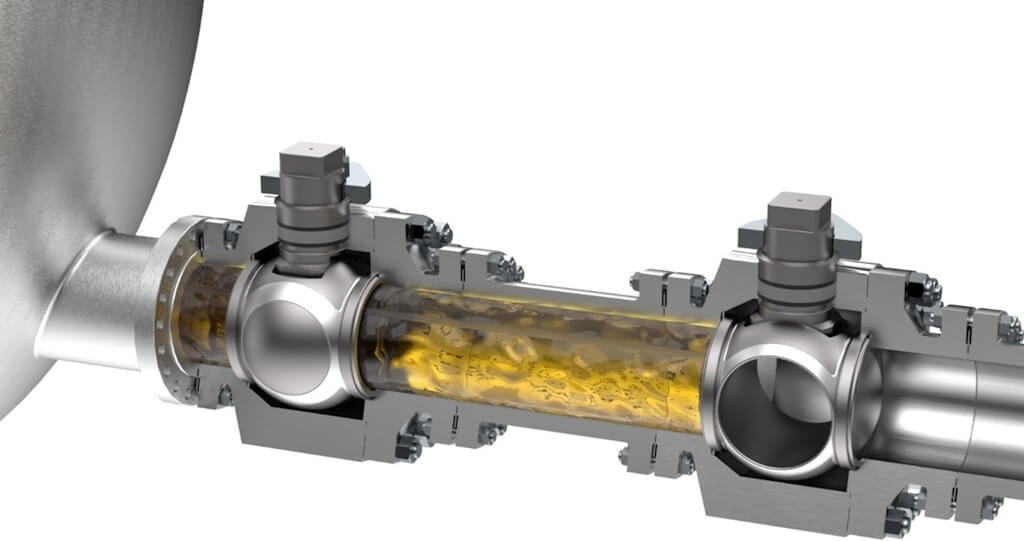

In the demanding world of High-Pressure Acid Leaching (HPAL) and Pressure Oxidation (POX), ball valves are crucial for slurry isolation and process control.

Ball valves used in these conditions must endure repeated cycling, differential pressures and continuous exposure to aggressive media. Standard valve trim solutions, such as thermal spray coatings, often fail prematurely due to coating delamination, corrosion and erosion, leading to inferior valve sealing performance, frequent unplanned maintenance, costly replacements and process downtime.

These systems operate under extreme conditions, including:

• Temperatures reaching 270°C

• Pressures exceeding 4,500 kPa

• Exposure to high velocity abrasive and corrosive acidic slurries

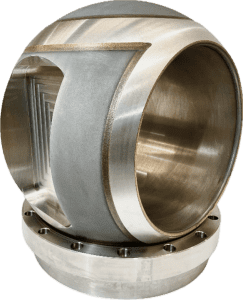

To address these challenges and overcome the failure mechanisms observed with the use of thermal spray coatings, Callidus Group developed (Fig 2), an advanced, surface-modified ball valve trim that revolutionises valve performance in HPAL and POX environments. This cutting-edge technology utilises multi-patented metallurgically bonded titanium nitride, offering excellent wear and corrosion resistance, extending service life up to five times longer than conventional coatings.

Challenges of traditional coatings applied on valve trim in HPAL & POX applications

1. Rapid degradation of thermal spray coatings

Traditionally, atmospheric plasma spray oxide coatings are applied on the ball and seats to enhance wear resistance in severe service ball valves. However, these thermal spray ceramic coatings suffer from several inherent limitations:

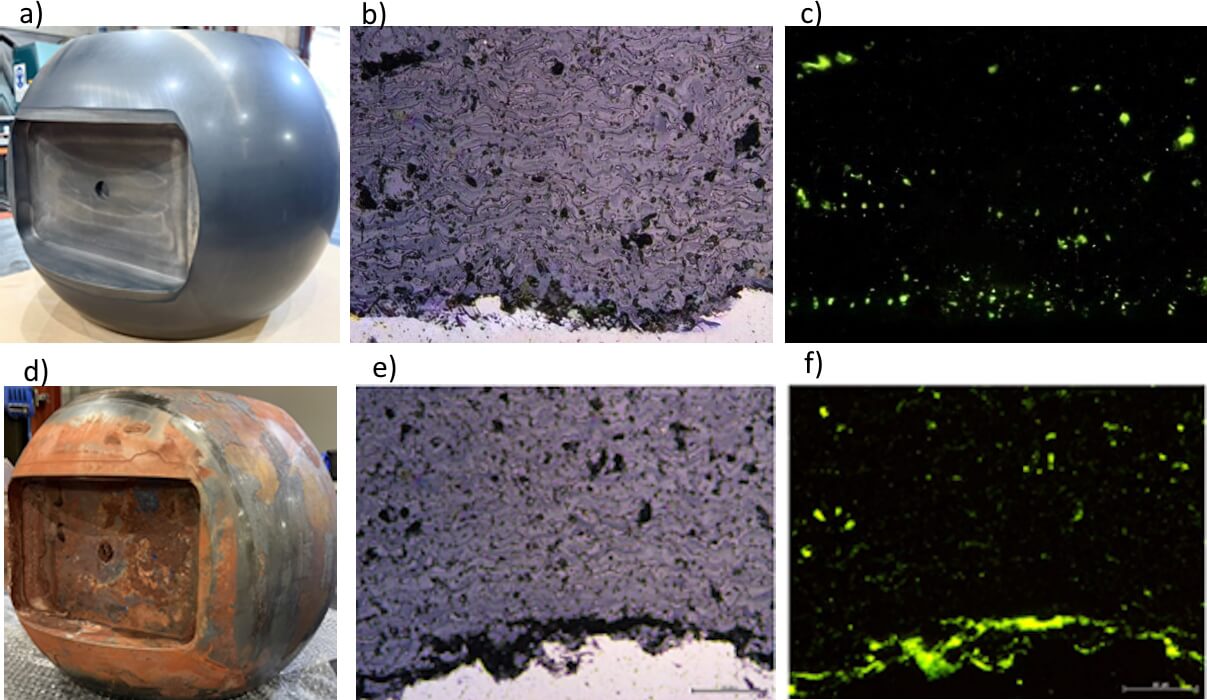

- Mechanical bonding issues: thermal spray coatings are mechanically adhered to the substrate, making them prone to delamination and stripped off under high-stress conditions, resulting in loss of sealing efficiency.

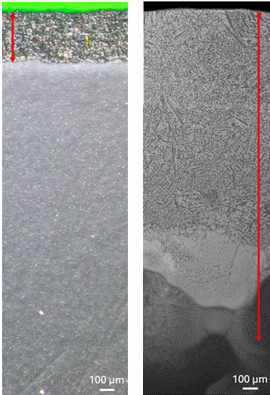

- Porosity concerns: the porous nature of thermal spray ceramic coatings allows acidic slurry ingress through the coating thickness, leading to substrate corrosion and premature failure of the thermal spray coating (Fig 3).

- Limited-service life: HPAL discharge valves located directly downstream of the autoclave typically experience coating failures within 6 to 12 months, requiring frequent valve replacements and shutdowns.

2. Corrosion and erosion of titanium valve trim

Titanium is widely used in HPAL valves due to its combined superior strength-to-weight ratio and corrosion resistance, but it has poor erosion resistance. When a thermal spray coating detaches, the titanium substrate is exposed to high-velocity slurry containing undissolved solids, and the titanium trim components experience rapid wear and galling, compromising sealing integrity.

3. Unplanned downtime and high maintenance costs

Frequent valve failure and replacement cycles in HPAL & POX operations result in:

- Increased operational costs due to frequent repairs and spare part replacements.

- Unplanned shutdowns, negatively impacting production.

- Reduced equipment reliability, causing cascading failures in downstream processes.

To solve these problems, FM-1500™ offers a breakthrough solution.

Looking ahead for severe service valve trim

FM-1500™ is a titanium nitride surface modification technology that provides exceptional wear and corrosion resistance. Unlike conventional thermal spray coatings, it metallurgically bonds to the titanium substrate, eliminating the risks of coating delamination, porosity and premature wear. FM-1500™ is available for both new valves and retrofit applications, making it a cost-effective upgrade for existing severe service ball valves.

Figure 3 The conventional thermal spray coating in (a–c) as-new and (d–f) post-service condition. (a, d) bright-field optical micrographs show coating crosssections; (b, e) corresponding fluorescent micrographs highlight porosity; (c, f) Zoomed-in fluorescence reveals through-thickness void networks. Inherent porosity in the as-new coating (b, c) enables acid ingress, triggering corrosion and delamination. Post-service images (e, f) show void coalescence and coating separation at the interface.

Outperforming testing

The technology was subjected to rigorous laboratory and field testing in real-world HPAL environments.

The testing procedure used internationally standardised ASTM test methodologies, including:

- Hardness testing (ASTM E92): where the FM-1500™ valve trim exhibited surface hardness, outperforming standard titanium (210 HV).

- Erosion resistance (ASTM G65 & ASTM B611): where the valve trim reduced wear volume loss by up to 90% compared to untreated titanium trim.

- Corrosion testing in 98wt% sulphuric acid at 200°C: where the technology demonstrated excellent corrosion resistance, maintaining structural integrity.

Key features & benefits of the FM-1500™ trim

| Feature | Benefit |

| Metallurgical Bonding | Prevents delamination and spalling failures (Fig 4) |

| 1,500 µm Modified Layer Thickness | 5x thicker than traditional coatings that are approximately 300 µm thick (Fig 4) |

| Hardness: Max 1,000 HV0.5 | Superior resistance to erosion and abrasion |

| Zero Porosity | Eliminates acid penetration and substrate corrosion |

| Universal Retrofit Capability | Compatible with all OEM valve designs |

| Proven 30+ Months Service Life | 5x longer than traditional thermal spray coatings |

A persistent problem: the six-month shutdown cycle

In a HPAL plant, a 14-inch Class 600 ball valve in the autoclave discharge line was a known weak point. Every six months, the valve would require a full changeout, forcing costly shutdowns. The culprit? The thermal spray coating, which routinely delaminated under extreme conditions. Once the coating failed, high-velocity acidic slurry would rapidly erode the titanium substrate, leaving the plant operators with no choice but to replace the valve entirely.

In pursuit of a more durable, long-lasting valve solution, the client conducted consecutive trials with advanced coating technologies from two alternative OEMs.

This cycle of failure and replacement was not only expensive but also a major operational headache. Process engineers sought a long-term solution—one that could withstand the severe environment without the repeated shutdowns.

A game-changing retrofit

A solution was proposed to evaluate the exisiting valve trim andretofit it with the FM-1500™ trim. The plant operators, wary after years of frequent failures, were cautiously optimistic but agreed to put the trim to the test.

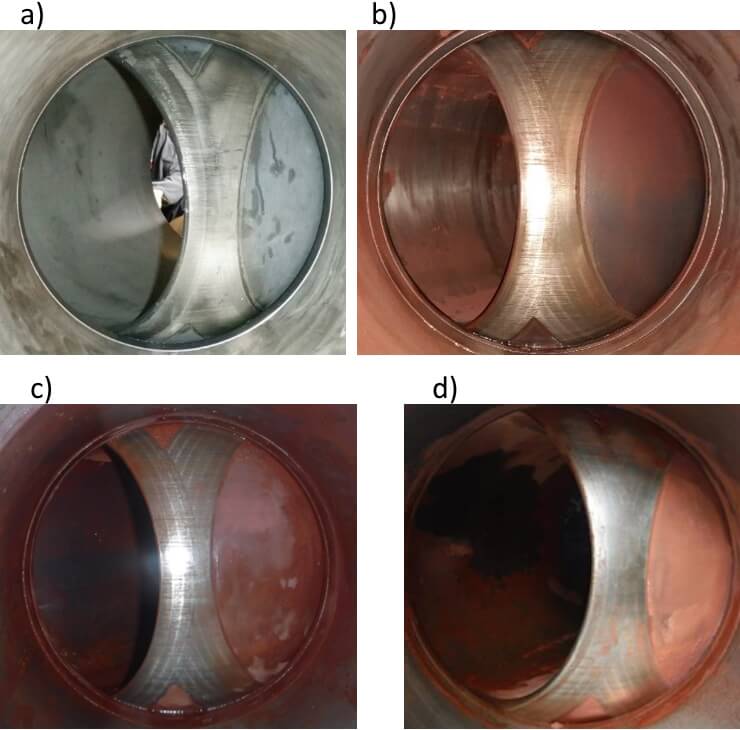

Inspection photos taken at regular intervals presents a robust trim (Fig 5).

Demonstrated performance and operational impact

The performance exceeded expectations:

- Maintained full sealing integrity despite sustained exposure to high-temperature acidic slurry.

- Eliminated delamination, demonstrating superior durability compared to thermal spray coatings over time.

- Required no unplanned maintenance, enabling continuous operation without disruption.

The service life increased fivefold, extending operational uptime from six months to over 2.5 years. This improvement resulted in significant cost savings, reduced maintenance interventions, and enhanced overall plant reliability.

Importance of evaluating valve trim

What can be seen from these results is that evaluating coatings and valve trims is extremely important.

When the most suitable trim is used in valves, such benefits will be noticed:

- Eliminates unplanned shutdowns, valve failures due to delamination and better reliability for HPAL and POX plants.

- Significant cost savings, such as reduced service intervals and the need for spare parts and labour costs.

- Trim that can be universally compatible, such as the FM-1500™ trim that can be installed in all OEM valve designs, requiring no modifications to valve actuation.

- Sustainability and reduced environmental impact as there are fewer valve replacements, meaning less waste and reduced resource consumption. Lower energy costs associated with shutdowns and replacements are also an added bonus.

Conclusion: the new standard for severe service valve trim

The FM-1500™ valve trim represents exciting innovation opportunities in severe service valve technology, offering excellent erosion resistance, corrosion protection and long-term sealing reliability. Whether for new valve installations or retrofitting existing ball valves, it provides an incredible performance advantage in the harshest industrial environments.

About the author

Evelyn Ng, PhD, MBA, is a Chartered Professional Engineer in both Australia and Canada and is based in Western Australia. With 15 years of experience in the resources sector, she specialises in materials performance and asset integrity in extreme service environments. Recognised at both the state and national levels with the Women in Resources Technological Innovation award, she is the Group Manager Materials & Innovation at Callidus Group. She is passionate about delivering practical, high-impact solutions that improve safety and extend equipment life.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, May 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”