Aalberts Integrated Piping Systems (IPS), a global leader in advanced piping systems for liquid and gas distribution, highlights its “Apollo”® API-607 fire-safe valves, engineered for protection and reliable performance in industrial environments. API-607 certification, developed by the American Petroleum Institute, is recognized worldwide as the premier fire-test standard for quarter-turn valves. “Apollo”® fire-safe valves minimize leakage during and after fire exposure, ensuring containment, regulatory compliance, and operational safety.

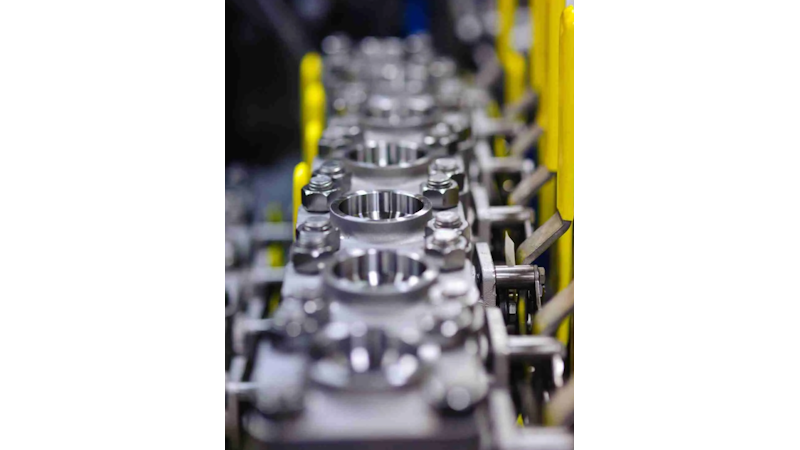

The “Apollo”® API-607 portfolio includes the 87A and 88A flanged ball valves, offered in stainless steel, carbon steel, and specialty alloys, with sizes up to 12 inches. These valves feature safety elements such as a blowout-proof stem, anti-static grounding, chevron-style adjustable stem seals, and a two-position locking device. Rated for up to 250 psi saturated steam, depending on class or option, they are suitable for natural gas, compressed air, and steam applications. The -24 fire-safe option meets 5th and 6th edition API-607 standards.

Complementing the flanged ball valves, the 83A-140 carbon steel three-piece full port ball valve features a rugged carbon steel body with stainless steel trim, enclosed fasteners, and a swing-out center section for easy maintenance.

Additionally, the 215 and 230 Series double-offset butterfly valves, available in wafer or lug body designs, provide high performance and durability for controlling liquids, gases, and steam. Stainless steel models are fire-safe certified with graphite seals, robust disc construction, and a 17-4PH stem, extending versatility across demanding industrial applications.