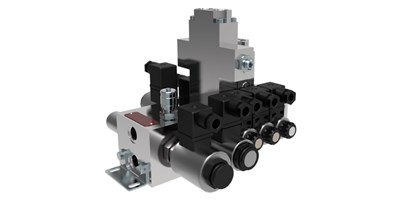

ARGO-HYTOS‘ new modular valve system RPEK1-03/B is flexible with a wide range of applications in mobile and stationary machinery. The RPEK1-03 sectional directional valve in size 03 with a maximum flow of 20 l/min (5.3 GPM) per section is the assembly’s basic component. Designers can create numerous schematics for open-center circuits thanks to a large number of horizontal and vertical sections, combined with screw-in cartridge valves.

The total manifold assembly consists of four sub-sections. The inlet section connects the entire manifold assembly to the pressure and tank lines of the hydraulic system. It is possible to add a pressure reducing or an unloading circuit by using standard 7/8-14 UNF (B2, C-10-2) screw-in cartridge valves. The inlet plate can be installed at the center of the assembly, and the module manifolds with valves can be connected to it on both sides. Up to 16 sections can be connected. The modular inlet manifold can be used for operating pressures of up to 250 bar (3,625 psi) and a total flow rate of 60 l/min (16 GPM). BSPP and SAE industrial standard threads are available for connection to the circuit.

Horizontal sandwich plates with cavities for any screw-in cartridge valve in size ¾-16 UNF (A2, C-08-2) allow for a range of control functions in ports A and B, which lead to the connected actuators. Valves that can be used include check valves and pilot-operated check valves; flow control valves and flow regulators; pressure control valves; over-center valves for load motion control; and any other solenoid-operated valves for directional control of the flow.

For vertical sandwich plates, ARGO-HYSTOS offers throttle valves with the bypass check valve, pilot-operated check valves, and many cover plates with horizontal and vertical ports to connect the actuators to individual sections.