Renowned hydraulics specialist Argo-Hytos commissioned system integrator Resim to design and build a fully automated system for the production of electromagnetic valves. High-precision SCARA robots from Stäubli perform all of the handling operations, the most challenging of which comes with the screwing and unscrewing of the valves at an end-of-line test station.

Argo-Hytos set automation partner and system integrator Resim the clearly defined task of automating to the maximum extent a previously manual production line for electromagnetic valves at its plant in the Czech Republic.

In planning the project, the Resim team of designers was not only able to draw on the experience gained from the company’s long and successful collaboration with Argo-Hytos but also on the expertise they had acquired over 30 years of industrial automation. An essential component of this know-how has been the recognition that, when precision and speed are the main criteria, Stäubli robots are the first choice.

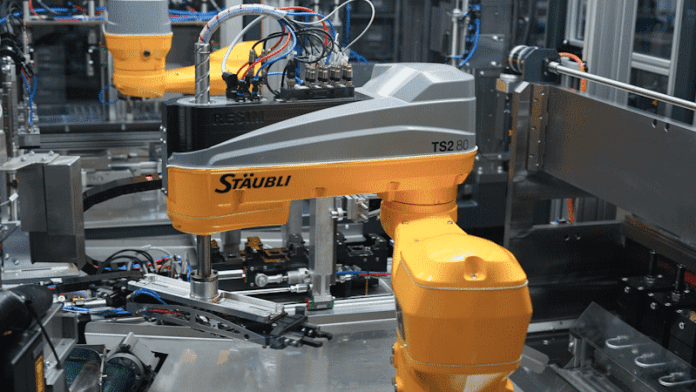

In this case, four TS2-80 SCARA robots take on the handling of the electromagnetic control valves during assembly and subsequent end-of-line testing. There are several good reasons for this. With a TS2-80, the system integrator can theoretically perform up to 200 gripping operations per minute. This corresponds to a cycle time of 0.33 seconds while maintaining high precision: Repeat accuracies of up to ± 0.004 mm in the Z-axis are possible for pick and place.