ASVAD may only have designed one product so far, but the Spanish company believes this unique valve can fill an important role in the nuclear power industry. In fact, ASVAD are confident that their valve is so special that it will be implemented at every PWR-plant in the world. Indeed, at the recent World Nuclear Exchange (WNE) in Paris, the company’s invention was nominated for the Nuclear Safety Innovation Award (SME category).

By Lucien Joppen/David Sear

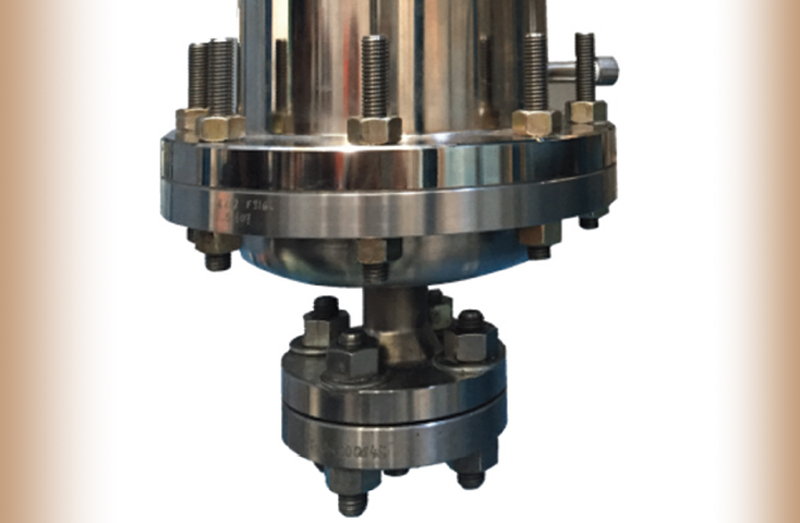

The World Nuclear Exchange 2021 in Paris was the fitting occasion chosen by ASVAD to launch its Automatic Safety Valve for Accumulator Depressurization, or ASVAD for short. At first glance this product may look like a standard safety valve, yet ASVAD are confident that, given its unique capabilities, the valve will be implemented in every Pressurized Water Reactor (PWR) plant around the world.

That was very definitely the message which Valve World received when we spoke to ASVAD’s CEO, Mr. Laborda, at the WNE. “The ASVAD valve is a genuine novelty and has been specifically designed to solve a problem that all PWRs may suffer during a Loss of Refrigerant Accident (LOCA). During such an event, nitrogen gas from the accumulators may unwittingly be injected into the reactor cooling system pipes. The complications of having non-condensable gases in hydraulic circuits are well documented, so if these circuits are ones that cool a nuclear reactor while it is suffering an accident, the problem acquires a much greater importance since it potentially can put the core cooling at risk.

Passive solution

Asked about solutions currently in place to prevent unwanted nitrogen injection, Mr. Laborda (who just happens to be a nuclear engineer specialized in reactor protection systems) says that utilities currently rely on emergency procedures to isolate or vent the accumulators. “These emergency actions will have to be developed by the emergency organization using the available equipment trying to fix the problem. However, consider a Station Blackout (SBO) like the one at Fukushima, when all the power and all the electric equipment will be lost. It is difficult or even impossible to develop emergency procedures for such situations. Therefore, having an automatic valve which can do all this work could be very helpful to the emergency team.”

Mr. Laborda continues: “the ASVAD works automatically in the event that the accumulator loses all its water. In that case, the valve opens and vents the pressurized nitrogen to the atmosphere. This prevents the nitrogen in the accumulator from reaching the reactor pipes. Important to note is that it actuates at precisely the required moment i.e., not too soon (which would result in the loss of the water still available), but not too late (resulting in nitrogen injection into the pipes). This means that the cooling system can be depressurized to lower pressures, greatly facilitating accident recovery.