Energy and water will be two of many key markets for AUMA. For the company, it is important to contribute to a more sustainable society. “Sustainability is deeply rooted in our genes”, says CEO Jörg Hoffmann. “Both with our products and in our own processes we aim to make significant contri-butions to reduce the CO2 footprint.”

By Lucien Joppen

Dr. Hoffmann has been at the helm of AUMA since January 1st 2018. The first four years of his tenure were quite eventful, to say the least, as 2020 marked the beginning of the pandemic. Fast forward roughly two years later, with the dust settling on Corona, it almost seems that the storm has passed somewhat, except for the war in the Ukraine that is.

Interestingly enough, it seems that many flow control companies have withstood the global turbulence. AUMA is no exception, says Dr. Hoffmann.

“Last year, our sales, order intake and profits exceeded our quite moderate expectations. Our previous efforts in developing our organization through higher vertical integration have also paid off in terms of creating a more efficient and effective operation, for example in on-time delivery even with challenging supply chain conditions.”

Supply chain challenges

As for 2022, AUMA has continued its course from 2021 and has made a successful start, according to Dr. Hoffmann. “Again, our order entry is higher than we expected. This is of course good news, but it also comes with the challenge to manage our supply chains accordingly. So far, we have done so but we notice that due to world-wide shortage of electronic components and the Ukraine-crisis, supply chain issues have intensified. Another side effect is that material costs have risen significantly. All in all, the company is still well on course, compliments to the team for their performance despite the tougher framework conditions!” Apart from the aforementioned disruptions, it is paramount for businesses to keep their eyes fixed on the long(er) term. Roughly two years ago, when Valve World first interviewed Dr. Hoffmann, he disclosed the strategic focus to future-proof the company for years to come.

Three pillar strategy

The above strategy is based upon three pillars: product innovation, digitalisation and international localisation. “New product development is an integral part of the evolution of AUMA,” Dr. Hoffmann says.

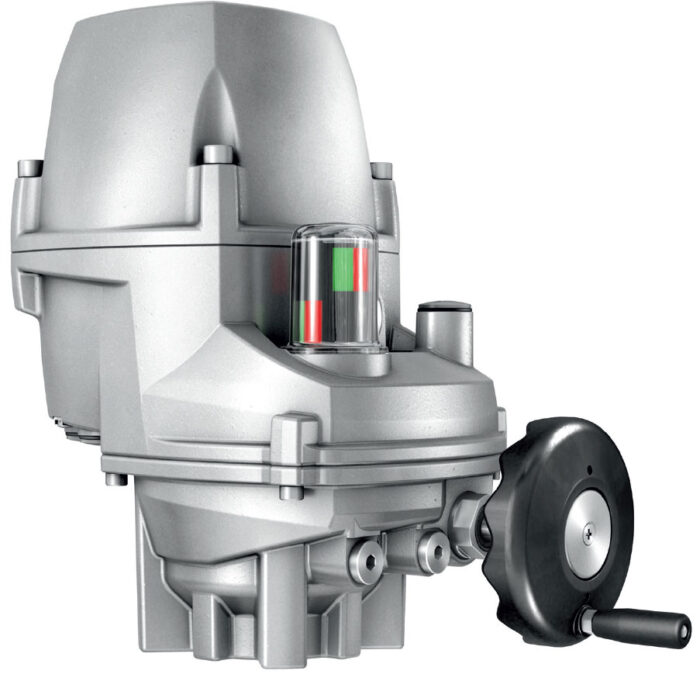

“A telling example has been the launch of the new PROFOX actuator.”

Digitalisation is a key trend in new product development, Dr. Hoffmann states. “Many customers are looking for smart solutions either to increase productivity and process safety or to replace human tasks. Therefore, we are working closely with our key customers to develop innovative solutions such as condition monitoring, where customers send data into the AUMA Cloud for performance analysis. Other customers are more focused on reliability, which we address through high-quality, robust actuation solutions. Different customers have different needs, and we make sure we have the products to serve them all.”

Safety paramount

As mentioned earlier, sustainability is im-portant to AUMA, equally for its customer base. Specifically for the energy sector, hydrogen – and to a lesser extent LNG – are hot and happening in many geographies across the globe. Dr. Hoffmann acknowledges the opportunities that will arise with this shift to low(er) carbon fuels/energy carriers.

“AUMA stands for solutions in all sectors with the aim of playing an important and reliable role in the construction, operation and maintenance of the infrastructure. When it comes to hydrogen and liquid gas, safety is what counts, which we support with our actuators and controls. Our actuators are built in such a way that they protect the system, the environment and people during operation and also in emergency situations. Our products have been ready for LNG applications for decades. The classic SA (rotary actuator series) and SQ (part-turn actuators) in the explosion-proof version have proven themselves worldwide.”

Digitalisation and safety

The new TIGRON actuator is also a prime example how digitalisation and safety go hand in hand, Dr. Hoffmann states. The actuator has been equipped with added features such as a power storage unit that continues to send important information about the actuator to the control room in the event of a power loss. Another feature is a remote control, which makes it possible to start up the actuator in difficult-to-access or dangerous areas. The FQM (mechanical fail safe unit) should not be missing from this list, because it enables safe operation in an emergency when the power supply is interrupted. As you can see, safety comes first.

Coming back to hydrogen, the above product lines are used to safeguard the transfer from the highly volatile gas. “In the storage of hydrogen, these actuators regulate the import and export. To prevent this highly flammable mixture of hydrogen and oxygen from posing a hazard, our actuators are used as a safety measure. In case of an emergency, they close the flow and prevent an explosion. In normal operation, they ensure a flawless process.”

Oil and gas here to stay

Parallel with the development of renewable energy, such as green/blue hydrogen, wind, solar and other modes, oil and gas are still needed to generate electricity and heat for various purposes such as mobility, residential and industry.

“Oil and gas will be with us as a source of energy in many countries for a long time to come. In this sector, it is important to make the processes safe and environmentally friendly with our products”, Dr. Hoffmann states.

“With our TIGRON oil & gas actuator, we have further developed a solution for oil & gas applications that provides the necessary safety for O&G companies, the environment and its employees. In addition to the safety provided by the design and the explosion protection that is achieved as a result, we offer other features with TIGRON that go beyond existing solutions. A good example is an independent power supply to supply the control room with current information about the actuator in case of an emergency.”

Water shortages

Apart from a more sustainable energy supply, water is another key challenge for the coming decades. An increasing world population and effects from climate change on local/regional water supplies are having an impact on water availability already, even within Europe.

Dr. Hoffmann states that AUMA is excel-lently positioned with its product gamma to address the water challenge from vari-ous viewpoints, for example in desalina-tion. “Since groundwater is limited in various geographical regions, seawater de-salination plants are becoming more and more popular as a sustainable solution. We provide key technologies for the con-struction and operation of these facilities. Huge amounts of water are transported in these plants – many filtration stages, re-verse osmosis and finally transport of the water – our actuators take on important tasks from control and pressure regulation to distribution.

In the distribution of fresh water to the customer, it is crucial to prevent loss.

This mammoth task can only be mastered through consistent automation and in-creased use of digital analysis and control mechanisms. This also holds true for sewage treatment in growing megacities, and this is where we at AUMA can fully contribute our strengths and design future solutions together with our customers.”

Modular platform

Speaking of solutions, the PROFOX range comes to mind. AUMA launched PROFOX in Q1 of 2020 just when the Corona pandemic started to conquer the world. At the time, the company had to think whether it should postpone the introduction or just go ahead. “It didn’t take long for us to decide to continue with the launch”, says Marc Schmidt, Head of international sales.

With PROFOX, AUMA has developed a new platform for smaller actuators in the lower torque ranges. These are suited to many industry segments, including modular water treatment skids, cogeneration plants, district heating and cooling, tunnel ventilation, and shipbuilding.

PROFOX actuators are designed as a modular platform, including part-turn, multi-turn and linear versions (in development) to suit a wide variety of valve types. Equipped with integral intelligent controls, PROFOX actua-tors provide enhanced diagnostic features and can accommodate fieldbus, Industrial Ethernet and OPC UA interfaces, making the actuators suitable for IIoT applications. Variable-speed DC motors ensure fast and precise valve positioning, enabling sophisti-cated closed-loop control applications.

Flooding risk

Flooding risk

In some cases, water is scarce, in other instances there is too much of it, even in regions where you do not expect it. Ashgal, the Public Works Authority of Qatar, decided to extend the E-Ring road in Doha and also upgrade the stormwater net-work. Several huge roller gates were installed in underground chambers to shut off DN 2700 stormwater pipelines in case of emergency.

The actuators to operate the huge roller gates had to be installed inside the cham-bers. As the chambers may become flooded during heavy rainfall, the customer was looking for actuators that can be immersed in water for extended periods of time. The total chamber height is 24.5 m, and the actuators had to be mounted approximately 6 m below ground level.

AUMA supplied powerful SA 30.1-UW underwater actuators that are suited for continuous underwater use at up to 15 m head of water. While the actuators were mounted on an access platform inside the chamber, the AC 01.2 actuator controls were mounted separately from the actuator outside the floodable area, using a wall bracket. ‘All local operation can therefore be done safely and from a comfort-able position using the AC 01.2 actuator controls’, AUMA states.

Source: Website AUMA

Digital solutions

As Mr. Schmidt stated, the introduction of PROFOX was almost entirely digital as countries were closing down during the introductory period. “These were very hectic but exciting times as we had to devise plans and ramp up in our capabilities to bring PROFOX to existing and new customers”, Mr. Schmidt states. “We have developed for example tutorials/instructional videos for PROFOX and other product lines to be included in our AUMA Academy, we organized virtual sales meetings, provided digital updates, and increased our presence on social media.”

According to Mr. Schmidt, these digital solutions – some of which were already in place – have ensured that the company kept in touch with its customer base. However, there is no substitute for face-to-face communication, he says. “We consider digital tools as an add-on. Once you get into contact with customers and colleagues during trade shows, such as recently at the IFAT 2022 in Munich, you realize the importance.”

Market gap

Coming back to PROFOX, Mr. Schmidt discloses that AUMA has shifted quite a few boxes of the product range. “Our customers and potential customers have reacted positively across the board. We are developing our products based on market intelligence and we have tested these concepts extensively, for example via usability studies. Therefore, we anticipated these reactions. When we positioned PROFOX, we saw a market gap for lower torque range actuators that are complementary to our mid- to large torque range actuators. This gap has been created by emerging small(er)-scale production units in various sectors, such as energy generation, water, industrial gases, hydrogen and so forth.”

According to Mr. Schmidt, there are several updates in the pipeline to increase the application scope of PROFOX. Certificates for ATEX are in the making and a linear version is due to be launched this year.

“Given the modularity of PROFOX, we will look at add-ons that bring value to our customers. We see a lot of room for growth for these lower torque actuators. The future is bright!”

For customers and society

“As you have seen, we at AUMA are acting in many ways to support our customers in safely operating their facilities while being a local and reliable partner for them”,

Dr. Hoffmann summarizes. “But that is not the only truth. Based on our traditions and beliefs, we live our responsibility for society considering that our employees are our key assets. We are proud of our worldwide team with whom we have achieved important milestones. That means worldwide local communities with whom we have always been in close partnerships. We take global CSR projects at heart while supporting organizations and people. The notion of sustainability is deeply rooted and lived within the AUMA culture”, Dr. Hoffmann states.

Localisation

Dr. Hoffman mentioned earlier the three pillars of AUMA’s future-proof strategy: product innovation, digitalisation and international localisation. “From its early beginnings, AUMA has expanded its presence across the globe, depending on the local situation and employing local experts”, Mr. Schmidt states. “This approach has proven the most effective for us as we want to be as close as possible to our local customers, to ensure agile and seamless deliveries and service in many locations, it also required to offer local content, for example by having manufacturing and/or assembly capabilities on the ground. Cur-rently, as I have said earlier, the Middle East region is very interesting from a greenfield perspective. This is part the reason why we will strengthen our presence in Saudi Arabia with a brand-new service center, including stock keeping and assemblage. Currently, we are servicing KSA from our Sales and Service Center in Dubai. This facility will remain as our hub for all our activities in the United Arab Emirates (UAE), Oman and North Africa.”

About this Featured Story

This Featured Story is an article from our Valve World Magazine July 2022 issue. To read other featured stories and many more articles, subscribe to our print magazine.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”