Severe service generally refers to applications that feature heavy particle involvement, high-frequency cycling, extreme temperatures, corrosion, erosion, or any combination of these factors. Metal-seated ball valves are required for these demanding conditions.

By Flowserve

The success of a metal-seated ball valve largely depends on the selection of a suitable hard coating and whether that coating is manufactured correctly. Hard coatings can protect vulnerable parts and enhance a valve’s performance. However, it is much more difficult than most valve end users would imagine to obtain a satisfactory hard coating. This is why it is still common to see a variety of coating issues in ball valves on-site, such as galling, cracking and even delamination.

Why do ball valves require coatings?

Soft seated ball valves have their limitations when it comes to high temperatures or severe conditions. To handle the loads between the ball and seats, and to ensure a reliable and long lifetime, a suitable coating is required between the moving contact areas. Additionally, to withstand abrasive, erosive, high-pressure, and high-temperature conditions or exposure to solids, the right choice and quality of base material and coating will impact performance such as tightness, endurance, torque and repairability of the valve.

General problems in severe service conditions

The harsh conditions in severe service environments are a challenge for the lifetime and sealing performance of the valve ball and seat. Only with a suitable material selection can the premature performance loss of the valve be avoided. High-pressure and high-temperatures, combined with solids, can lead to galling or even chipping and destruction of the coating. This may result in increased torque and a non-operable valve and/or a high leakage rate. The same applies to corrosion, erosion or abrasion when the wear resistance of the coating is not adequate.

Recommended solutions

HVOF and Spray & Fuse coatings are two commonly used coatings in the valve industry. The advantages and applications of these two coatings (regardless of powder material) are shown in Table 1.

What makes a good coating?

The coating production process can be likened to the creation of an artwork, with all steps, including pre-treatment, spraying and post-treatment, contributing to the final result. Imperfection in even one of these steps will lead to a failed product. In many cases, the problems are insidious, it might just be a slight increase in the torque required for valve operation.

Spraying is the most critical link in the process. A proper spraying process shall be as precise and stable as possible. Spray is a process of material addition that must be controlled carefully. Just like machining, state-of-the-art equipment is not the only factor to consider; suitable fixtures and years of experience are also crucial. Stability is all about process management; once a perfect spraying process (pre-heat, speed, distances, etc.) is achieved, it is essential to ensure that all these steps are implemented in future with minimum intervention. To be more cost-competitive, some manufacturers still use manual spraying; however, this approach is not recommended as it is neither precise nor stable.

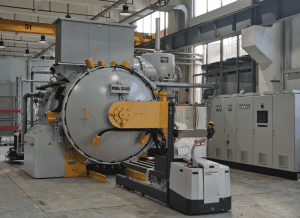

Heat treatment refers to the fusing step in the Spray & Fuse coating process. Valve users increasingly accept Spray & Fuse coating as a more suitable coating for severe service applications, such as flushing and thermal shock, than HVOF coatings. The fusing process of most Spray & Fuse coatings in the market is achieved by manually heating the ball seat with an oxyacetylene burner. This is highly dependent on experience, so it is difficult to guarantee temperature uniformity all over the ball set, which may lead to a coating with uneven quality. To obtain a reliable and high-performance coating, it is recommended to use a high-precision vacuum furnace which ensures a minimal temperature variation during the fusing process.

Lapping plays an important role in producing high-quality coatings. Standard lapping processes only ensure sufficient roundness around the sealing area. If we extend the area of measurement to the whole ball, it may already exceed the tolerance requirements. This is why many metal-seated ball valves exhibit relatively acceptable performance during factory testing; however, unacceptable leakage occurs due to coating damage caused by just a few open-and-close cycles once the valve is installed. Therefore, in addition to spray capability, skilled lapping capability needed to ensure the ideal roundness all over the ball. Furthermore, a good lapping process will also guarantee an even coating thickness so that even hardness is achieved.

Testing and verification check that coatings are produced to the desired quality, and also provide continuous improvement instructions. The coating inspection method used in the valve industry generally includes hardness, porosity and bond strength tests on specimens. However, it has limitations: the test results can only verify that the coating satisfies the criteria in international standards, and a coating verified on a specimen doesn’t guarantee the same performance under real working conditions when applied to a ball set. An alternative solution can resolve this: test the coating performance under conditions simulating, but stricter than, the real valve working conditions, and use standard coating inspections as supplementary testing.

Summary

This article has discussed how hard coating can enhance the performance of ball valves, the challenges that severe service applications pose for ball valves, and some potential solutions. Although hard coating can extend a ball valve’s working scope and improve its performance and lifespan in severe service applications, this strictly depends on the quality of the coating. Sub-quality coating is a problem that can quickly create issues with a ball valve, resulting in poorer performance than a soft-seated ball valve. Therefore, special attention must be given to the quality control of the coating to prevent unexpected situations.

About the authors

- Dai Guangzhou, Senior Engineer, GDai@flowserve.com

- Henry Wang, Site Engineering Manager (Suzhou, Isolation Valves), HeWang@flowserve.com

- Thorsten Hecht, Global Engineering Leader (Argus Valves), thecht@flowserve.com

- Dr. Felix Tiggemann, Global Head of Surface Technology (Arguloy etc.), ftiggemann@flowserve.com

- Jörg Hoenicke, Product Specialist (Argus Valves), jhoenicke@flowserve.com

About this Technical Story

This Technical Story is an article from our Valve World Magazine, August 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”