As a member of the Technical Expertise Team at Ludwigshafen, Alexander Hein deals with automated valves in various production plants across BASF’s oldest and largest Verbund site.

“From the naphtha crackers to the units that produce specialized chemicals, our team has an impact as valves and actuators are indispensable for a safe and efficient production. There is still progression possible, especially in the domain of digitalisation making more use of the positioners, the valves’ interface to the automation systems”.

By Lucien Joppen

Alexander Hein (28) joined BASF a year ago, making a switch from academia to the private sector. Alexander has also joined the Steering Committee for the Valve World Conference 2022, replacing his colleague Matko Dijkman. But first, a step back into Alexander’s career before BASF.

“My background is in technical physics which I studied at the University in Kaiserslautern. I also took courses in electrical and mechanical engineering. Through my university education and experience as an intern with Bosch I became more and more attracted to business challenges such as product development and actual production. My last research project at university aimed at commercializing a new technology of tunable optical filters for which I worked together with several industrial partners to optimize material supply, their performance and the device production workflow. This project management experience and the technical understanding I gained were helpful for my career start at BASF. I now work in interdisciplinary teams and contribute with technical expertise to find the most suitable valve for the given process conditions.”

Powerhouse

Although Alexander thoroughly enjoyed his tenure at the University of Kaiserslautern, he decided to switch from academia to the private sector in 2021. “I came into contact with BASF through my alumni-network. During one of the regular alumni meetings where also BASF employees made presentations about their work and shared their experiences at the company, I became interested in making a switch. BASF is a household name in Germany and in the international chemical sector. The brand stands for innovation and state-of-the-art technology. We are one of the largest chemical producers in the world and active in all the major countries (80-plus) around the globe. Who wouldn’t want to work for such a powerhouse?”

True, a brief look at BASF’s company profile and product portfolio shows the broad scope of base and specialty chemicals, advanced plastics, surface technologies, nutrition & care and agricultural solutions.

Within this huge company, with its Verbund-structure and various joint-ventures, Alexander and his team provide (technical) support for valve technologies in various aspects of global projects, from specification, engineering, procurement and commissioning up to advice during the overall life cycle of the valves.

Shared insights

The Verbund-site in Ludwigshafen also harbors a valve workshop where valves can be tested and refurbished/repaired. Insights from these activities add value to the technical support and advice the unit provides to the plants in Ludwigshafen. However, the team also shares these insights with their colleagues abroad. “It is important that we reach out and communicate for the benefit of the company and its employees. Critical valves are essential elements in assuring a safe and efficient production process.”

When asked about his first year at BASF, Alexander mentions that one of his work’s focus is to improve the interchangeability of (pneumatic) actuators. “If we want to change an actuator, the modularity is important, i.e. such changes shall not involve time consuming adaptions of the valve stem and coupling. We also would prefer having the flexibility of selecting a valve we have on stock for replacement and not being dependent on specific models from specific suppliers.”

IPM

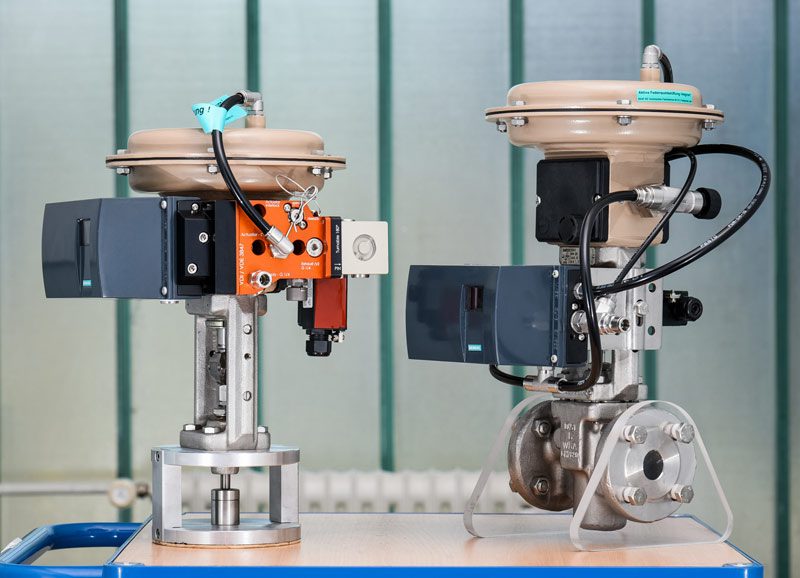

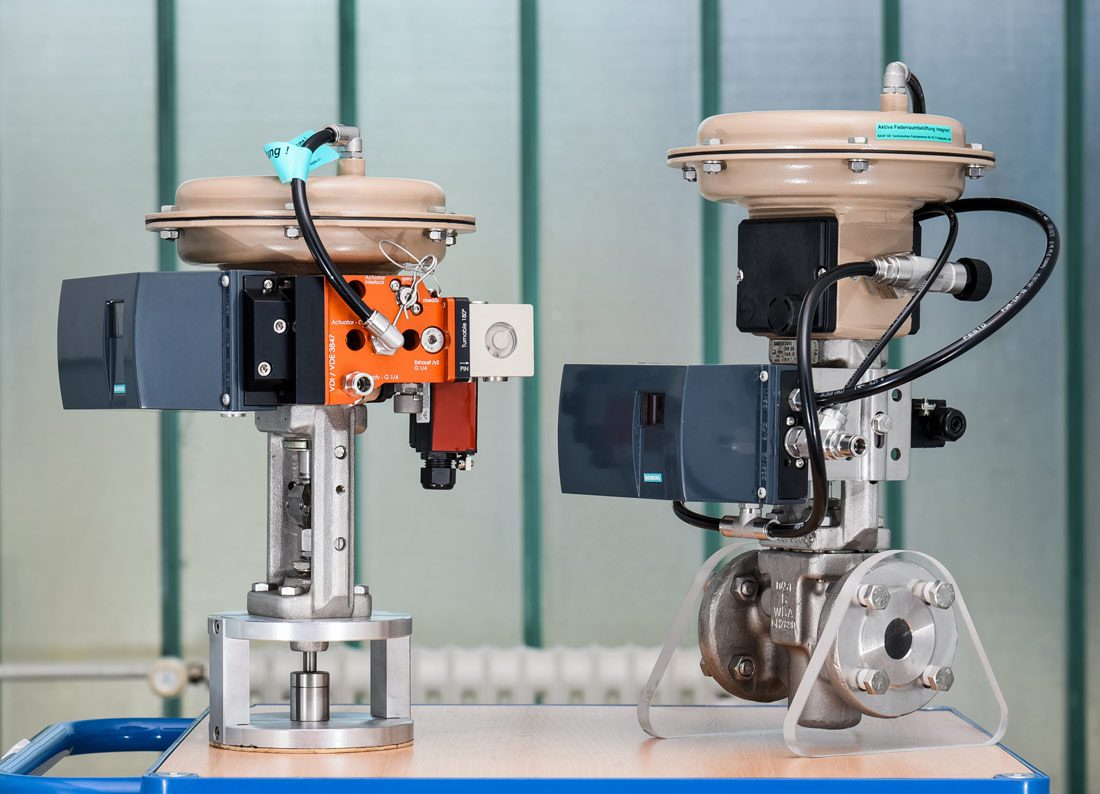

The Integrated Pneumatic Module (IPM) is another example of harmonisation and standardisation within the multinational’s flow control portfolio. The IPM (see Valve World April 2020) has been co-developed and introduced by BASF mainly to simplify the configuration for linear and quarter-turn actuators, both in standard and more complex configurations.

“The IPM has been designed to prevent unnecessary mistakes in the installation and maintenance process. The IPM also has potential in plant availability, safety and savings, for example in stock keeping.”

Hein states that the IPM has led to a reduction in complexity for service personnel on the ground that has to deal with these valve/actuator configurations and experience at first-hand the complexity of these systems.

At the moment, the IPM is in use within BASF after years of development, testing and taking other companies along, both end-users and suppliers, in the necessary standardization effort in the Namur- and VDI/VDE-committees.

Close Cooperation

Alexander stresses that in his current project, BASF has opted for a cooperative model with valve suppliers. “We are interested in long-term cooperations with our suppliers. We are talking about assets that are in operation for decades. Just to focus on invest cost might not be favorable since lower quality products may lead to higher operating costs due to maintenance and subsequent product loss. When we work together with our suppliers in such a way, we can reach their commitment to support our long-term developments leading to more value in the end.”

Critical in the valve life cycle is monitor-ing of the valve’s condition during its operating life. Alexander says that easily accessible static data such as device configuration is helpful for documentation purposes, but also sees a high future po-tential in making use of time-dependent dynamic data. “We are able to extract dynamic data such as the current supply pressure or the percentage of stroke from the positioner, which combined with other (production) parameters, indicate if the valve operates within an acceptable range. Together with our valves and DCS partners, we are developing this further to incorporate this practice into our monitoring and predictive maintenance program. In essence, we would be able to zoom in on potential problematic valves earlier and easier. For example, we would be able to correlate valve data with other process parameters and gain deeper insights from data recorded during partial stroke tests.”

BASF’s first Verbund-site

Since Friedrich Engelhorn founded BASF in 1865, the Ludwigshafen-site has developed into one of the largest integrated chemical complex in the world. A good third of BASF’s global workforce works here, and the site in Ludwigshafen is home to most of BASF’s operating divisions and numerous corporate units.

The BASF headquarters is also the origin of the Verbund-principle, which has been developed and continuously improved here. Ludwigshafen was, therefore, the model for BASF’s five other Verbund-sites in Europe, the US and Asia.

Many innovations started life in Ludwigshafen, from the pioneering work in dye production in the nineteenth century to the Haber-Bosch process for the production of ammonia and the high-pressure syntheses in the first half of the twentieth century, to today’s extremely versatile high-performance plastics or active ingredients for crop protection products. BASF Ludwigshafen in numbers:

~39,000 employees

~200 production plants with more than 10.000 valves

6 business segments

~230 km of railway lines

~2,850 km pipes

~106 km of roads

Valve digitalisation

With the aforementioned topic, digitalisation comes into the picture. BASF is active in this field to streamline its operations, including flow control equipment. “We are working on a digital platform in the cloud which contains (technical) data regarding our assets out in the field. This data is stored in a particular, uniform format so that there are no supplier-specific deviations.

Our colleagues in the field are then able to tap into the data by scanning QR- or RFID codes that are attached to related equipment. This modus operandi greatly reduces time spent in the field and potential confusion due to inadequate access to documentation. Similarly, we are working on a procurement platform which standardizes and harmonizes our procurement processes, irrespective of the vendor or product type.

Valve World Conference 2022

Finally, why did Alexander join the Steering Committee for the Valve World Conference 2022 and what does he expect from the event?

“There are various reasons: first of all, it enables me to connect to fellow experts in the field, coming from various sectors. This allows me to keep up with the latest developments in flow control, in various industries and geographies. Of course, I would also like to represent BASF’s interests on an international stage. As was the case with IPM, industries need to team up to address these challenges from an (inter)sectoral perspective!”