By Lucien Joppen

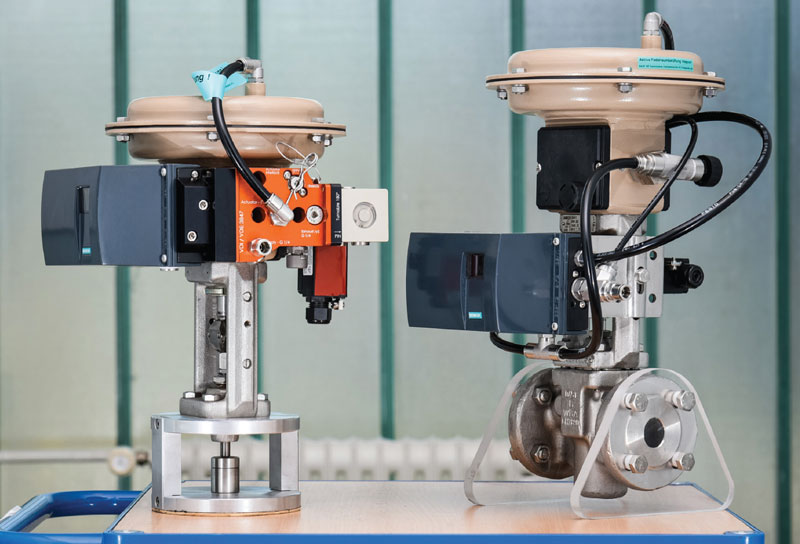

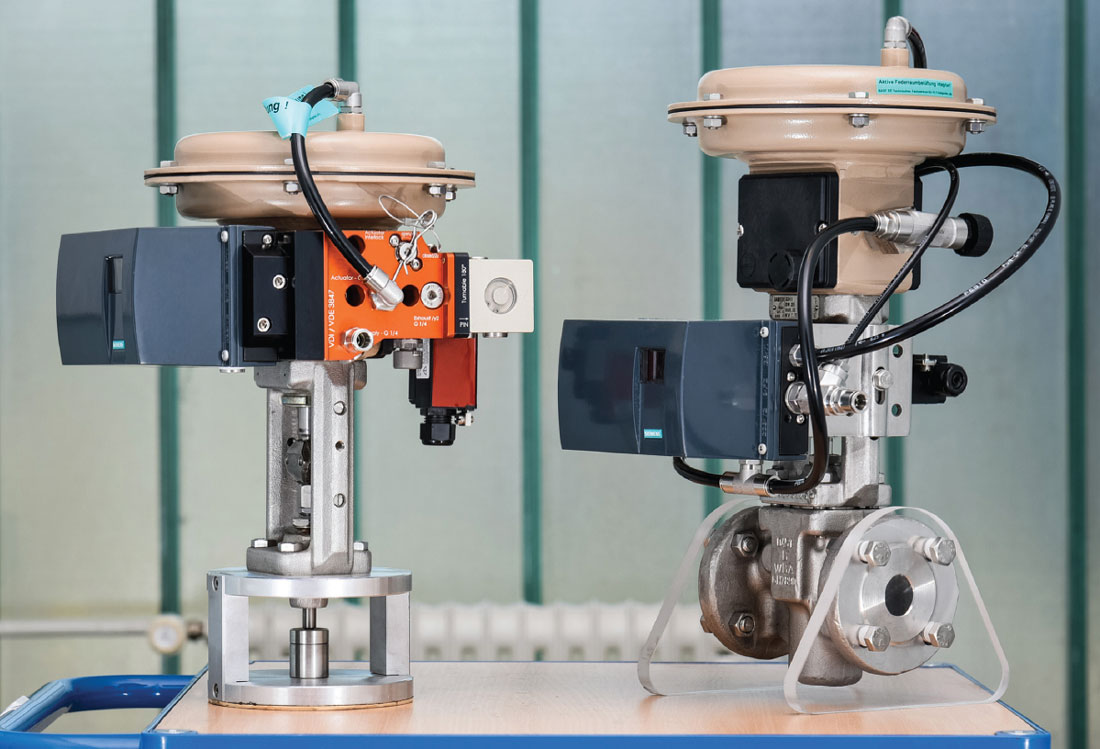

BASF has co-developed and introduced the Integrated Pneumatic Module (IPM) mainly

to simplify the configuration of linear and quarter-turn actuators, both in standard and more complex configurations. According to Matko Dijkman, Senior Automation Manager at BASF, the IPM has been designed to prevent unnecessary mistakes during installation and maintenance processes.

The IPM also brings potential benefits for plant availability, safety and savings, for example, in stock keeping.

Valve World visited Dijkman at the oldest Verbund-site of BASF in Ludwigshafen. In the enormous com-plex (See box on page 31), it takes roughly 20 minutes by car – the maximum speed is 30 km/h – to the Service Center where Dijkman’s office is located. He heads the Global Service Center for Automated Valves at the German chemical powerhouse.

Dijkman (see page 32 for biography) has been active in instrumentation in general and later

on more specifically in automated valves. When asked what attracts him in this domain, he men-tions complexity. “No configuration (valve, actuator, instrumentation) is the same. This complexity also leads to vulnerability of the production process. As BASF’s Service Center for Automated Valves, it’s a challenge for us to improve these devices and harmonize where we can. Naturally, the Service Center is heavily involved in servicing/repair and (re-)assembly of the valves that are installed in Ludwigshafen. Advising our business units is also part of our job. For example, which valve/actuator configuration is needed for a certain application or a recommendation to use adapted pieces if needed.”