Biogas plant in Australia, modernized by Weltec. With food waste as feedstock, the electricity generated powers both the facility itself and a sewage treatment plant, with excess energy exported to the electricity grid.

Bioenergy, the generation of power from organic matter, is a major and growing industry that plays a crucial role in the circular economy. However, its undoubted advantages come with a few drawbacks, including its high costs.

By James Chater

Background

It may surprise advocates of solar and wind energy, but bioenergy accounts for 55% of renewable energy and over 6% of the world’s energy supply, or five times the combination of wind and solar PV (1). This sector of the renewable energy industry has been growing rapidly and has received a further boost from rising energy prices following the Russian invasion of Ukraine, sanctions on its oil and gas exports and the Europeans’ replacement of Russian piped gas with more expensive LNG from the USA. The IEA considers bioenergy to be an important part of the transition to net zero emissions. Demand is rising more quickly in Brazil, India and Indonesia than elsewhere. All have abundant feedstocks and are net energy importers. Not only these countries but also North American and European governments have programmes and directives in place to boost bioenergy production with the help of subsidies and incentives: for example, the USA’s Higher Blends Infrastructure Incentive Program.

Biomass

It is usual to distinguish three generations of biomass (the organic feedstock used to create biofuels):

- Edible crops such as corn, sugarcane, palm oil or soybeans, which are used to make ethanol.

- Non-food biomass such as waste (agricultural or domestic), wood, switchgrass, etc. For example, several pilot projects are scaling up production of cellulosic ethanol, especially in the USA and Europe.

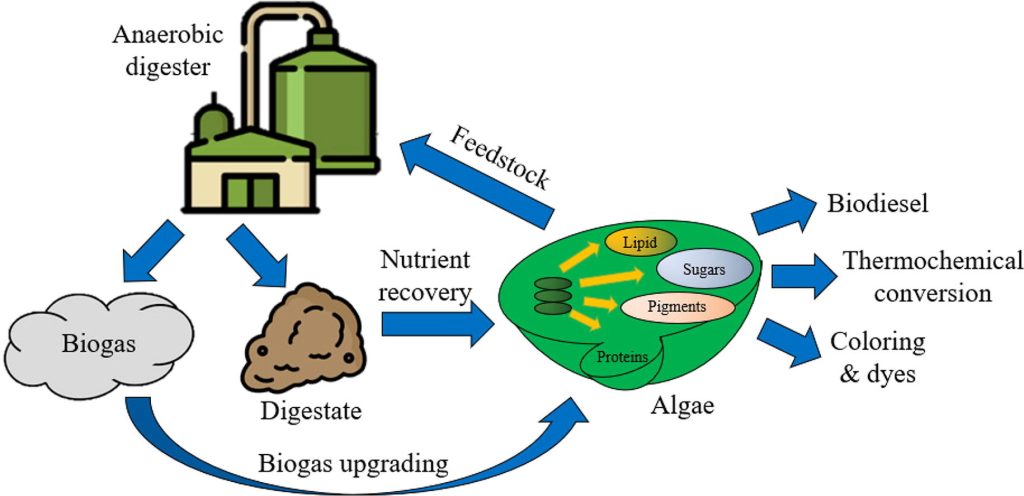

- Algae, which can be cultivated on non-arable land and have higher oil content, making them ideal for biodiesel and jet fuel. Algae production has recently gained renewed interest through efficiency gains, for instance closed-loop systems that recycle water and nutrients. It is also gaining interest as a means of wastewater treatment through biosorption, bioaccumulation and intracellular degradation.

“Weed” to energy

Hemp has the potential to be a rich source of ethanol/methanol and biodiesel. Research is not yet far advanced, but initial tests of hemp fuel suggest they are less carbon-intensive and cheaper to produce, while burning them emits up to 80% less greenhouse gases than traditional gasoline. The feedstock in question is industrial hemp (Cannabis sativa L.), which is similar to but not identical with the psychoactive plant known as marijuana (²).

Biofuels

Some of the most common biofuels include:

- Ethanol. The most common biofuel, produced through the fermentation of sugar and starches and cellulose (second generation). It can be blended with gasoline. An important producer is Brazil, where ethanol is made from cellulosic biomass such as bagasse.

- SAF. Sustainable aviation fuels are a viable solution for aircraft, where electrification is a very limited option. It can be produced from waste oils, agricultural residues and CO2 captured from the atmosphere. United, Delta and Lufthansa are among the airlines committed to using SAF, and Shell and BP are building facilities to produce it.

- Biodiesel is produced from oils or fats using the chemical reaction transesterification. Along with LNG and hydrogen, it is a promising candidate fuel for HGVs and large ships. It can be blended with traditional diesel. In 2002, West Central (later Renewable Energy Group) opened one of the world’s biggest continuous-flow processing plants for processing soybean oil into biodiesel fuel.

- Biogas (biomethane) is a mixture of methane and CO2. Its feedstock is normally waste or agricultural residues, and one of its most common uses is in waste to energy (WtE). Bacteria break down the feedstock in the absence of oxygen (anaerobic digestion) to produce biogas, which can be injected into the gas grid or used to generate heat and/or electricity (combined heat and power). A byproduct of the process, called digestate, is a good natural fertiliser.

- Syngas, or synthetic gas, consists of hydrogen and carbon monoxide, often with some CO2 and methane. It can replace gasoline and is also used to produce ammonia or methanol.

Pros and cons

The main argument in favour of bioenergy is that it decarbonises the production of energy by relying on feedstock that is self-renewing: the CO2 absorbed by plants as they grow offsets some of the CO2 emitted during the manufacture process. (In addition, Bioenergy Carbon Capture and Storage – BECCS – can be applied.) The case for biofuels is especially powerful for heavy-duty transport systems where the prospects of electrification are limited: jet aircraft, large ships, HGVs, heavy industry (Outokumpu, for example, is building a pelletising plant that will allow it to replace fossil coke with biomass in its stainless-steel production).

A third advantage of bioenergy is the opportunity to cut waste and advance the circular economy. Waste-to-energy (WtE) in combination with district heating is an example of how to kill two birds with one stone: disposing of waste that would otherwise have to be incinerated or sent to landfills (a major source of methane emissions) while heating homes at lower cost and with fewer emissions. Other benefits include enhanced energy security and a boost to local economies.

Apart from anaerobic digestion, other processes used in WtE include incineration/combustion, which produces heat for district heating or electricity; gasification, which involves heating in a controlled, oxygen-limited environment to produce syngas; and pyrolysis, where biomass is heated to high temperatures in an oxygen-free environment to produce gas for energy or solid and liquid materials that can be refined as bio-oil and chars.

Critics of bioenergy point to the high costs and dependence on subsidies (does bioenergy make sense when the costs of wind and solar have been plummeting?), competition with recycling (diversion of waste that could otherwise be recycled), technological challenges (many processes have been implemented only recently) and the “food versus fuel” argument, which maintains that biofuels take up land that could be used to grow food (an objection that applies more to first-generation than later biofuels).

Valves

In biomass treatment processes, various types of valves can be used depending on the specific application and requirements. Valve selection depends on factors such as the type of biomass being treated, operating conditions, pressure and temperature requirements and the desired flow control characteristics.

In anaerobic digestion, micro-organisms break down biodegradable material in environments without oxygen. The process is used for waste management and fuel production; anaerobic digestion gate valves are used in this process.

Another type of valve found in a biogas plant is the ‘slam shut’ isolation valve. Here, butterfly valves can be most useful.

Dive Deeper into Valve World

Enjoyed this featured article from our March 2025 magazine? There’s much more to discover! Subscribe to Valve World Magazine and gain access to:

- Advanced industry insights

- Expert analysis and case studies

- Exclusive interviews with valve innovators

Available in print and digital formats.

Breaking news: Digital subscriptions now FREE!

Join our thriving community of valve professionals. Have a story to share? Your expertise could be featured next – online and in print.

“Every week we share a new Featured Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”