In an era of energy transitions, Omniseal Solutions is moving toward a sustainable future by developing advanced sealing solutions for different types of energy, focusing on low-carbon technologies such as hydrogen, ammonia and carbon capture.

By Christophe Valdenaire, Omniseal Solutions

With a heritage of serving the energy sector, Omniseal Solutions has consistently been working on sealing and material innovation by solving rising challenges in valve sealing operating conditions and enabling progress toward a carbon-neutral future. By leveraging decades of material science and design expertise acquired with valves for offshore deepwater production, cryogenic valves and low-fugitive emission valves, the company’s technical experts are continuing to engineer advanced Omniseal® polymer and metal sealing solutions to support decarbonisation.

As the major source of global greenhouse gas emissions, the energy sector holds the key to respond to 2050 global net-zero ambitions. This requires a gradual shift away from fossil fuels and the implementation of technologies that enable the mitigation of emissions in hard-to-abate sectors. In order to deep cut emissions, green hydrogen and its derivatives as well as carbon capture, utilisation and storage (CCUS) are several viable options today that are being accelerated and pushed by public and private sectors who are injecting billions in funding projects.

These low-carbon emitting technologies are pushing the boundaries of non-metallic sealing materials in different areas to cope with the needs of the engineered valves market:

- Gaseous hydrogen requires soft sealing materials with low permeation and resistance to rapid gas decompression to ensure leak-tight performance

- Liquid hydrogen at 20°K up to 100MPa requires a unique set of soft sealing materials and designs

- Ammonia transfer requires soft-sealing materials with excellent chemical resistance and tribological properties

- Carbon dioxide requires soft-sealing materials with excellent chemical resistance when exposed to impurities and resistance to rapid gas decompression

To meet technological challenges posed by the new energy mix requires an in-depth knowledge of the industrial processes in place and how they impact the design of valves. Omniseal Solutions relies on its relationships with valve manufacturers as well as main EPC companies to anticipate new needs in high-performance sealing materials and solutions. Long-term collaboration combined with a strong investment in research and development in innovative fluoropolymer science result in precision sealing solutions that deliver enhanced durability, effective leak prevention and reliable performance. This strategic approach has also resulted in a major achievement their thermoplastic material certification, verifying that its material reduces its carbon footprint and successfully handles various critical challenges of decarbonisation.

Certification of thermoplastics

To ensure safe transport and storage as well as prevent leakage from various components in the value chain, e.g., valves, wellheads, compressors, pumps and loading systems, soft sealing materials and their durability are often scrutinised. Sealing and material companies, such as Omniseal Solutions, are often asked about assessing the behaviour of these sealing materials and their integrity in challenging environments.

NORSOK M-710 provides materials and functional testing for critical non-metallic (polymeric) sealing, seat and back-up ring materials and components. The intent of NORSOK M-710 is to ensure that non-metallic sealing material manufacturer and end user have sufficient understanding and experience with the applicable materials to be reassured that they will give acceptable performance in the specified environment.

Catching CO2 with certified thermoplastic materials

The compatibility of soft sealing materials for exposure to CO2 and impurities in dense phase CO2 service needs to be considered and various failure modes have been identified. Soft sealing materials can be split into two sub-categories: elastomers and thermoplastics, with each exhibiting different behaviours because of their intrinsic properties.

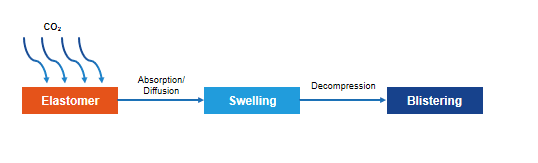

According to published technical papers, elastomeric seals can undergo severe degradation, i.e., chemical ageing, swelling and blistering with “impure CO2” blends containing SOx, NOx, O2, H2S and Brine. CO2 at high pressure can diffuse and dissolve in elastomeric materials. The initial sorption of CO2 into elastomers results in swelling, which changes their mechanical and physical properties.

The most important effect during the sorption is the reduction in Tg, often called plasticisation. Furthermore, blistering of elastomeric seals is caused by absorption/diffusion of CO2 at high pressure often creating catastrophic failure when depressurised, called Rapid Gas Depressurisation (RGD). (see Figure 1).

With elastomer seals, it is not always possible to provide a straightforward summary of what makes an elastomer RGD resistant or high performance in CO2 applications. Rather, it is more practical to rank the elastomeric seals by their relative resistance to RGD.

For thermoplastic polymer materials, evaluation is more straightforward, in which one considers their higher modulus and their higher resistance to fracturing or blistering from RGD. This methodology is done to an extent that RGD testing of thermoplastics are not required by the oil & gas industry standards such as NORSOK M-710 and ISO 23936-1. It is also well known and proven that thermoplastics can withstand CO2 impurities such as H2S, oxygen, steam, benzene, xylene, toluene and carbonic acid (if H2O and CO2 react to form it).

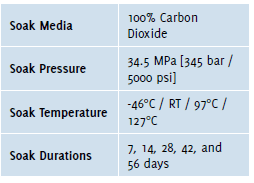

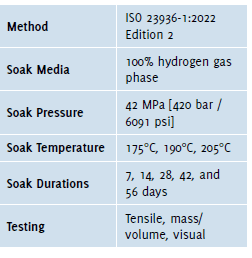

In partnership with an energy major, Omniseal Solutions’ technical team collaborated on a 100% CO2 certification campaign of several proprietary thermoplastic materials that consisted of a bespoke immersion testing in compliance with the pass/fail criteria of NORSOK M-710, Edition 3.

The following are the test conditions (the selected pressure / temperature conditions ensure testing in liquid and supercritical CO2):

According to these test results, every selected material successfully passed the acceptance criteria for tensile properties, mass and volume change, proving these materials are a better option compared to standard elastomers for sealing applications when exposed to CO2. All third-party certificates are available upon request.

Safe low-carbon ammonia transfer with certified thermoplastic materials

Ammonia is already a commodity product in various sectors but with 185 Mt produced in 2020, the sector was responsible for around 1% of global GHG emissions. Bloomberg NEF (Source: Scaling Up Hydrogen: The Case for Low-Carbon Ammonia, November 28, 2023) has identified 185 low-carbon ammonia projects totalling 28.7 Mtpa that will be produced in regions where conditions favour the production of renewable energy. As such, ammonia is a promising hydrogen carrier and fuel to decarbonise maritime industry. To ensure further safety and increase the capability to handle large, expected import quantities, new technology must be developed and existing technology for storage, transportation by ships and/or pipeline and (off)loading should be upgraded.

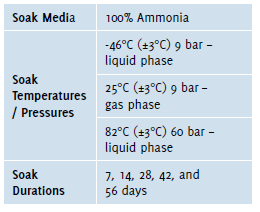

To proactively contribute to the safety effort necessary for the development of decarbonised ammonia and in partnership with major players in the sector, Omniseal Solutions has conducted a complete thermoplastics materials testing programme, ranging from aging to tribological characterisation. In doing so, the company can provide valves and transfer equipment to customers with reliable and durable sealing solutions quickly.

To proactively contribute to the safety effort necessary for the development of decarbonised ammonia and in partnership with major players in the sector, Omniseal Solutions has conducted a complete thermoplastics materials testing programme, ranging from aging to tribological characterisation. In doing so, the company can provide valves and transfer equipment to customers with reliable and durable sealing solutions quickly.

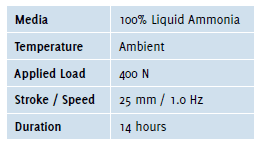

The following are the test conditions for ageing in compliance with NORSOK M-710, Edition 3 and ISO 23936-1:2022:

According to these test results, every selected material successfully passed the acceptance criteria for tensile properties, mass and volume change. All third-party certificates are available upon request.

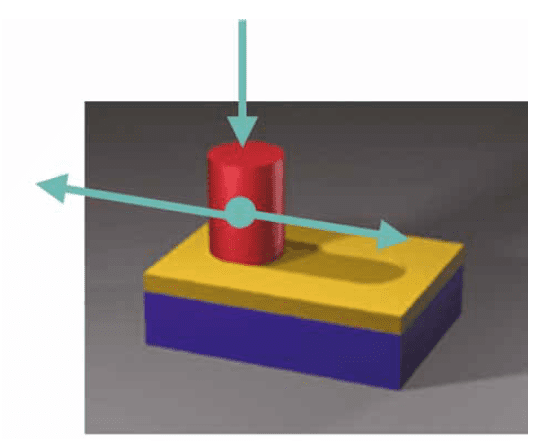

Furthermore, pin-on-plate tribological testing was performed on the same thermoplastic materials in 100% liquid ammonia to characterise their coefficient of friction and wear mechanisms.

Based on the composition of each tested material, the behaviour of wear and the ranking of each material is in line with expectations and not impacted by liquid ammonia. The measured CoF is also considered very well within the expectations.

Safe hydrogen pipeline transport with certified thermoplastic materials

According to consulting firm Guidehouse, Inc. paper titled “European Hydrogen Backbone Implementation Roadmap” published in April 2024, building a H2 pipeline network is central to the energy transition but needs public support as a catalyst.

A H2 pipeline infrastructure allows for H2 to be produced in low-cost renewables regions and delivered to demand centres. The European Hydrogen Backbone (www.ehb.eu), which is based on existing and new pipelines, gathers the main transmission system operators. The use of existing natural gas pipelines for hydrogen transport, whether through blending hydrogen with natural gas or through dedicated hydrogen pipelines, presents a variety of technical challenges, especially concerning material compatibility and sealing performance.

Hydrogen, being a much smaller molecule than natural gas, requires careful consideration in its transport infrastructure. The following are some of the key challenges specific to selecting sealing solutions in pipeline transport systems:

- Permeation risks: due to its small molecular size, hydrogen poses a higher risk of permeating through seals. To mitigate leakage, it is vital to use sealing materials with low permeability.

- Material degradation: hydrogen embrittlement can progressively weaken metal components. It is recommended that you select sealing components that can resist hydrogen penetration and degradation to uphold pipeline integrity and performance.

Omniseal Solutions collaborates with various valve industry partners and participates in technical committees focused on developing new regulations for hydrogen valves. In response to the growing trends and industry needs, the company has initiated an ageing test for seven of its Fluoroloy® materials, ensuring full compliance with the recently introduced Annex M of the API Specification 6D. For more details on API 6D Annex M, you can read the article by Jonathan Geleijns and Matthew Doherty, SLB, titled “API 6D Annex M-Setting the Standard for Hydrogen Valves” in the December 2024 issue of Valve World magazine.

Sealing solutions for a safer & sustainable future

As shown by the above rigorous material testing campaigns, Omniseal Solutions is committed to supporting the future of energy transition as it translates into a more diversified energy mix. The business will continue to work together with its long-term partners who rely on expertise to develop high-performance, precision-engineered sealing systems that meet the demanding requirements of hydrogen ecosystem and CCUS. By using advanced certified fluoropolymers and thermoplastics materials, safety and reliability of fluid transfer equipment can be ensured.

About the author

Christophe Valdenaire has more than 30 years of experience in metal and polymer engineered sealing solutions for the oil and gas valve industry. He is currently Senior Business Development Manager – Alternative Energies at Omniseal Solutions. In this role, he focuses on aligning the Omniseal Solutions’ products and materials offering for hydrogen and its derivatives, CCUS, biofuels and still for traditional oil and gas with strong focus on subsea, floating production, LNG transfer and emission control.

Christophe Valdenaire has more than 30 years of experience in metal and polymer engineered sealing solutions for the oil and gas valve industry. He is currently Senior Business Development Manager – Alternative Energies at Omniseal Solutions. In this role, he focuses on aligning the Omniseal Solutions’ products and materials offering for hydrogen and its derivatives, CCUS, biofuels and still for traditional oil and gas with strong focus on subsea, floating production, LNG transfer and emission control.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, May 2025 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”