Q: I’ve been asked to give a presentation to a group of new employees at our plant on control valve sizing. While I size an occasional control valve, could you outline some of the more important points for me?

A: Refer to Figure 1. There are graphs of the installed characteristics of two different valves installed in the same system. (These are equal percent valves, and the system has a lot of pipe.

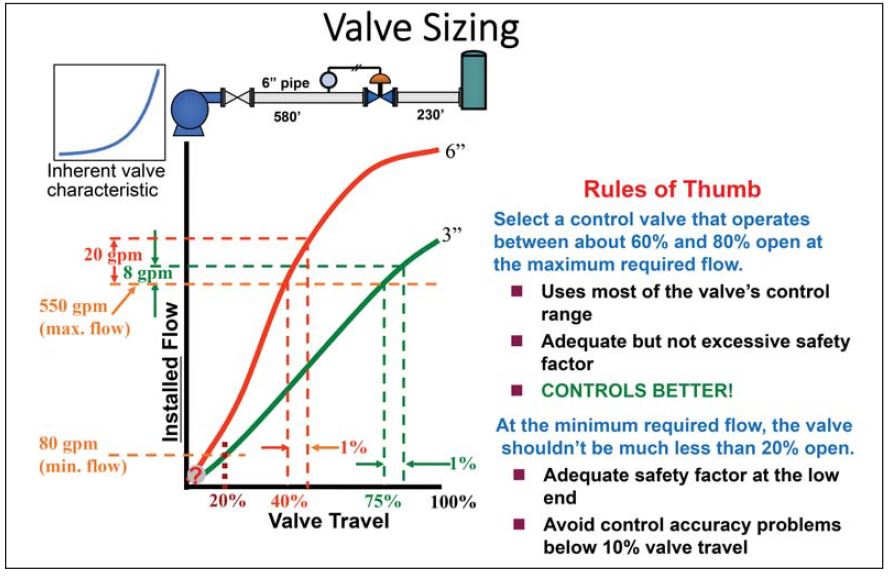

Note that they have reasonably linear installed characteristics up to the specified maximum flow rate of 550 gpm.) The 3-inch valve (lower curve) is correctly sized, and the 6-inch valve (upper curve) is oversized. The reason I say that the 3-inch valve is correctly sized is that it meets the criteria of the rule of thumb of being between about 60% and 80% open at the maximum required flow of 550 gpm. This rule of thumb has served valve users well because it gives a good balance between using as much of the valve’s control range as possible, and giving good flow resolution while providing an adequate safety factor. (The 3-inch valve can increase flow by about 20% above 550 gpm, which should be adequate, while the 6-inch valve can increase the flow by about 60% above 550 gpm, which is more than should ever be required.) In the rest of this column, we will see how proper sizing adds up to better control.

If the correctly sized 3-inch valve opens by one percentage point, the flow increases by 8 gpm. If the oversized valve opens by one percentage point, the flow will increase by 20 gpm. All valves exhibit a certain amount of stickiness. After a valve has been in service for a long time, especially if someone has been a little overzealous in adjusting the packing, it is not unusual to find that the smallest increment the valve can move is 1%. Anyway, for the sake of discussion, if the best each of these valves can do is to position themselves in 1% increments, the 3-inch valve will be able to control flow within 8 gpm increments, and the 6-inch valve will only be able to control flow within 20 gpm increments.

In general, the more oversized a control valve is, the poorer the accuracy of control will be. It is preferable to have a minimum opening of about 20% to provide some safety factor at the low end, but this isn’t always possible. Some key points to keep in mind are: A control valve sized to operate at around 60% to 80% open at the maximum required flow will give the best control.

Properly sized full ball, segment ball and high-performance butterfly valves are usually two sizes smaller than the line. Properly sized globe valves are usually one size smaller than the line. To avoid potential control problems at the low end of the control range, the valve opening should not be much less than 20% whenever possible. Valve manufacturers typically publish Cv tables beginning at 10 percent, so you have no idea what is happening below that point. Oversized control valves are very common. The pressure drop (ΔP) used in sizing calculations cannot be arbitrarily specified but must be based on a static analysis of the system at each design flow rate.

For a more detailed discussion of this subject, and others, see the Professional Development page of my website.

About the author

Jon F. Monsen, PhD, PE, was a control specialist with over 45 years of experience in the control valve industry. He lectured nationally and internationally on the subjects of control valve application and sizing. Jon’s website, www.Control-Valve-Application-Tools.com freely shares articles, training and professional development materials, and Excel worksheets that might be of interest to those who use or specify control valves. Jon passed away in December 2023 and his series of columns is being published in accordance with his wishes.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, March 2024 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”