Q: When I use my control valve sizing application for sizing a control valve for gas service it asks for the density or the compressibility factor of the gas. One application I have used always inserts a compressibility factor of one. Is using a factor of one satisfactory? If not, where do I look for the correct value?

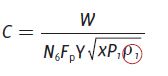

A: The basic gas control valve sizing equation given in ISA-75.01.01-2012 and IEC 60534-2-1 (Second Edition), when arranged to be solved for “C,” takes the form shown below:

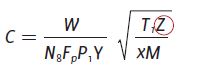

C is defined as being either Cᵥ or Kᵥ depending on the value of N₆. This equation requires a value for the upstream density of the gas where the symbol for density is ρ (rho). The equation assumes that the user knows an accurate value for the density. There are accurate tables for a few gasses, the best example being steam, but such accurate information is not readily available for most industrial gasses. The standards (actually the ISA and IEC standards are nearly identical) make allowance for this fact by including two additional equations. These equations, one based on mass flow units (symbol W):

and a similar one on volumetric flow units at standard conditions (symbol Qs) substitute for the upstream density a calculation of density based on the ideal gas equation using the molecular weight of the gas, its upstream pressure and upstream temperature.

To correct for the fact that a calculation of the density of a gas using the ideal gas equation does not always duplicate actual behavior, the standards include the compressibility factor (symbol Z) to include the degree to which a particular gas does not follow ideal gas behavior. Determining the value of Z is outside the scope of the Standards.

For many common industrial gasses at the pressures and temperatures they are normally used, a compressibility factor of one is often, but not always, good enough.

In the past, whenever I needed to size a valve for a gas, I used to look up the compressibility factor using the Nelson-Obert Generalized Compressibility Charts.

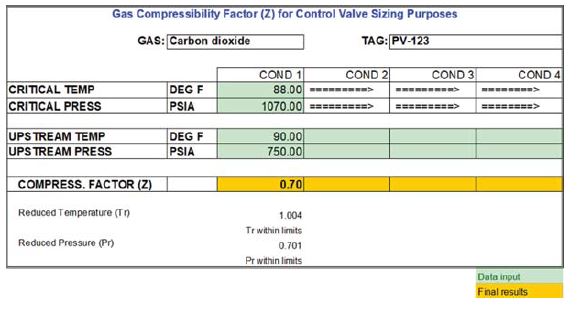

Some time ago I got tired of reading the Charts, which require some visual interpolation (and eye strain) and made an Excel sheet where I tabulated a lot of reduced pressure and reduced temperature points from the Nelson-Obert charts and included a two-dimensional interpolation scheme that yields a compressibility factor for any gas that I can find the critical pressure and temperature for. Below is a screen shot of the sheet showing a calculation for carbon dioxide. The calculation in the figure shows a compressibility factor of 0.7. In this case, assuming a compressibility factor of 1.0 when it is really 0.7 would result in a Cᵥ calculation that would be about 20% high. When the compressibility factor decreases, so does the calculated required valve capacity (Cᵥ or Kᵥ). The worksheet includes a “Read Me” tab with additional information.

A copy of the Excel sheet can be downloaded from the Worksheets page of my website at no cost. The sheet is valid for reduced temperatures (Tr) between 1.0 and 15 and reduced pressures (Pr) between 0.0 and 20. The worksheet shows the reduced pressure and temperature being used in the calculation and informs the user whether each is within the limits of the worksheet. There is space on the worksheet for four calculations to make it easily compatible with the four calculations performed by most control valve sizing applications.

About the author

Jon F. Monsen, PhD, PE, is a control valve technology specialist with more than 45 years of experience in the control valve industry. He has lectured nationally and internationally on the subjects of control valve application and sizing. Jon currently hosts a website, www.Control-Valve-Application- Tools.com where he freely shares articles, training and professional development materials, and Excel worksheets that might be of interest to those who use or specify control valves. He can be reached at cvapptools@gmail.com.

About this Technical Story

This Technical Story is an article from our Valve World Magazine, December 2023 issue. To read other featured stories and many more articles, subscribe to our print magazine. Available in both print and digital formats. DIGITAL MAGAZINE SUBSCRIPTIONS ARE NOW FREE.

“Every week we share a new Technical Story with our Valve World community. Join us and let’s share your Featured Story on Valve World online and in print.”