DeZURIK’s wide product line includes many unique special construction options for demanding services. One of these proven applications is a one-piece hardened seat/retainer for the VPB V-Port Ball valve for use in recycle paper mills.

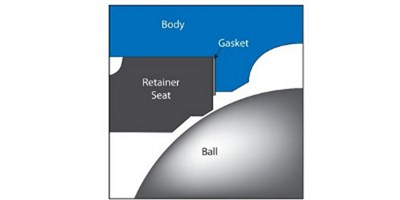

This specifically designed Recycle Reject Trim Package includes a one-piece 17-4 pH H900 heat-treated retainer and clearance seat. The clearance seat provides maximum controllability and minimum hysteresis in applications that do not require tight shut-off. This bi-directional seat combined with the hardened components is the perfect solution to the highly abrasive recycle reject flow control applications on primary and secondary screens in the stock prep area of the mill.

This unique trim package is another solution to address the most difficult applications in the stock prep area of the recycle paper mills. The DeZURIK VPB valve, combined with a Stainless-Steel Spring Diaphragm or PowerRac Actuator and digital positioner, makes an extremely attractive severe service package. DeZURIK is one of the few valve manufacturers that offer solutions for all the severe service, isolation, and control applications for recycle pulp and paper mills.

The Secondary Fiber Repulping diagram in the Valve Solutions for Pulp & Paper Guide, page 27, has been updated to show where VPB valves with the one-piece hardened seat can be installed.