In December 2020,ESA launched a database of validated gasket characteristics according to the European standard EN 13555.

By Dr.-Ing. Manfred Schaaf

The ESA is operating the database ESAdata.org as a service for their members and for the general industry. The data is verified by each manufacturer and independently validated and approved for publication by an ESA Task Force to ensure consistency and accuracy. The database is freely accessible on https://www.ESAdata.org.

It has grown continuously over the past three years, and the reputation of this source for reliable parameters has increased steadily. Some months ago, ESA announced the next step in the development of ESAdata.org. The design has been completely revised, and the selection and filter options have been significantly expanded for the user. In addition to the previously possible selection criteria such as gasket manufacturer and gasket type, the gasket material, the tested gasket geometry, the test temperature, the test pressure and the achievable tightness class can now be preselected.

The ESA thus provides a tool to easily obtain reliable, validated, and approved gasket characteristics according to EN 13555 to carry out mathematical proofs of strength and tightness according to EN 1591-1. Some software manufacturers use the data interface of the webtool and transfer these characteristics directly into their calculation software tools. So, the application of the calculation rule, which is very complex in itself, is made significantly easier.

Gasket characteristics in EN 13555

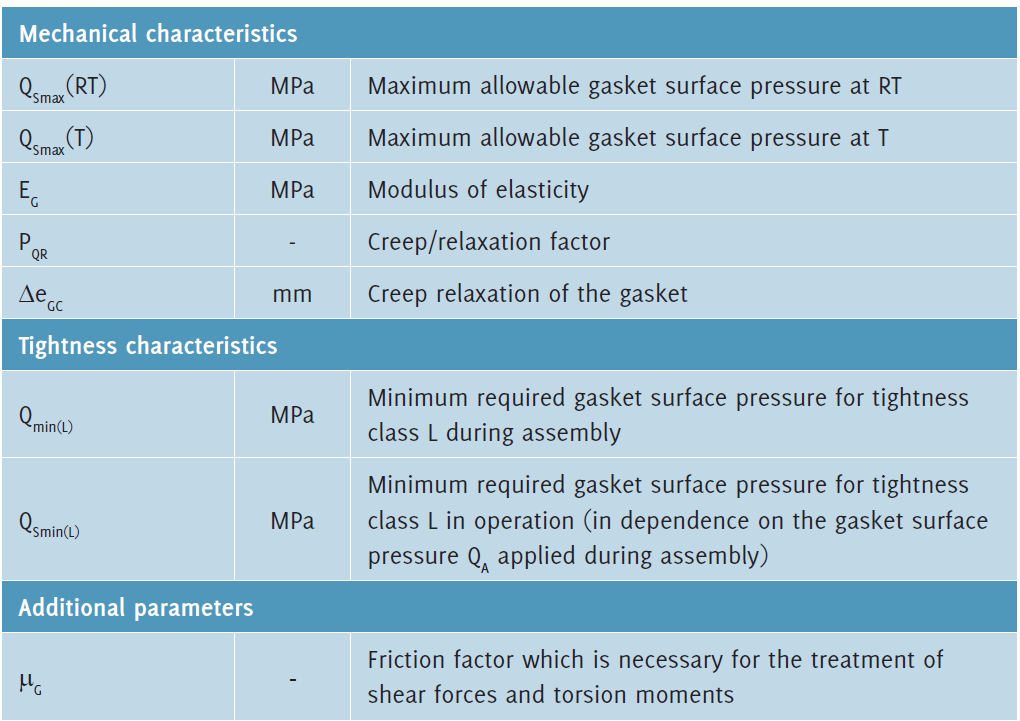

For the selection of a gasket and for the calculation of the bolted flange connection for the given requirements (loads, media, demanded tightness class) according to EN 1591-1, gasket characteristics are defined in EN 13555; these gasket characteristics are listed in Table 1.

Some characteristics describe the mechanical behavior and others the tightness behavior of the gasket materials:

- The maximum gasket contact stress QSMAX that can be safely applied to the gasket at the service temperature without damaging the gasket.

- The modulus of elasticity EG of the gasket at the service temperature describing the recovery capability of the gasket.

- The creep relaxation factor PQR or the additional deflection eGC of the gasket due to creep relaxation effects.

- The minimum gasket surface pressure in assembly condition QMIN(L) required at ambient temperature to achieve the tightness class L.

- The minimum operating gasket surface pressure QSMIN(L) which depends on the assembly gasket stress QA and which is required to meet the tightness class L.

In addition, the friction factor μG between the gasket material and flange surface, which is necessary for the treatment of shear forces and torsion moments, is newly defined in EN 13555. Incidentally, most of the friction factors μG published today were determined in an ESA research project from 2016 to 2017.

Concept of the database

The ESA Task Force is the most important body regarding publishing gasket characteristics on ESAdata.org. It consists of at least six staff members of different ESA Flange Gasket Division (FGD) member companies. The ESAdata Task Force is responsible for the commitment of the cross-check tests, for the approval of the gasket characteristics for publishing, and for clarifying published characteristics.

All gasket manufacturers have the possibility to be represented on ESAdata.org with their gasket materials, if they fulfill all specified requirements: ESA or FSA membership, providing characteristics based on test results and ten reference samples, acceptable divergency of double test results and approval of characteristics by the ESAdata Task Force.

All gasket values must be determined by double testing. The test parameters, testing equipment and test results must be documented in a test report, including photos. The divergence between the double test results needs to be within the defined limits, which are based on the experience of ESA members. The submitted report and evaluation files of all tests are verified and checked on plausibility (by comparison with test results of similar gasket materials) and on the compliance of the permissible divergence of the double test.

After the verification, a cross-check is done unless the characteristics have been determined by an independent testing house, or if there are justified doubts about the values. The characteristics determined in the crosscheck on one of the supplied reference samples must be within the permissible divergency compared to the originally supplied characteristics, otherwise the data cannot be published. Thus, the highest level of reliability of the published data can be guaranteed.

Design and function of the database

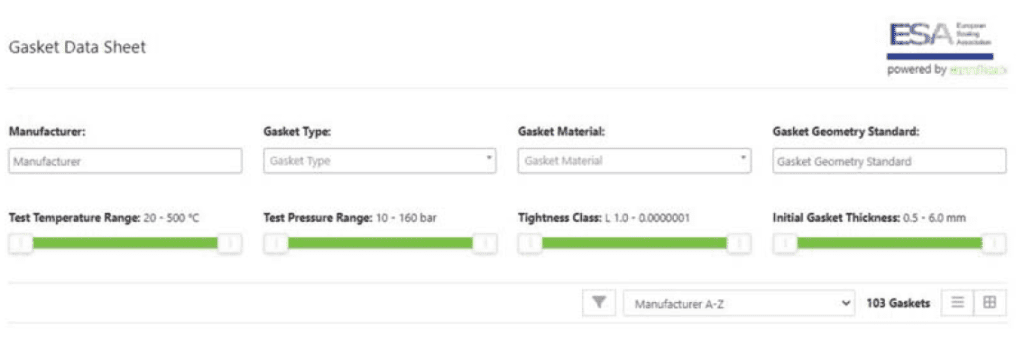

The homepage of the website offers various selection boxes and sliders, which can be used to filter the displayed data sheets; see Figure 1.

The drop-down menus contain predefined values set by the ESA Task Force for the best possible categorisation of the different gaskets. The manufacturer selection box is self explanatory. For the gasket type a grouping has been made, which is also largely reflected in the European standards for the gasket geometries:

- Sealing tape

- Sheet gasket

- Sheet gasket with PTFE envelope

- Rubber/steel gasket

- Kammprofile gasket

- Spiralwound gasket

- Metallic gasket with flat or corrugated profile (type SC)

- Metallic gasket with flat or corrugated profile (type CR)

- RTJ gasket (oval type)

- RTJ gasket (octogonal type)

- Metal-coated jacketed gasket with layer

- Lense gasket

- Metal gasket with curved surfaces

The gasket material, which includes the plate material, the coverings, or the fillings, but not the carrier materials, is categorised in:

- PTFE

- Graphite

- Fiber

- Silicate

The standard specifications can be found in the drop-down list of the gasket geometry standards, whereby a distinction is made as to whether the gaskets are used in PN or Class designated flange connections:

- PN designated EN 1092-x “Raised Face” (EN 1514-x)

- Class designated EN 1759-x “Raised Face” (EN 12560-x)

- PN designated EN 1092-x “Tongue/Groove”

- Class designated EN 1759-x “Tongue/Groove”

- Non-standard

The limits of the sliders, on the other hand, are automatically adjusted based on the contents of the database. Therefore, the exact limits of the available gasket parameters are shown by these values. This applies to the test temperature, the test pressure, the tightness class and the nominal gasket thickness. By simply sliding the slider, the selected gaskets can then be restricted for all these parameters.

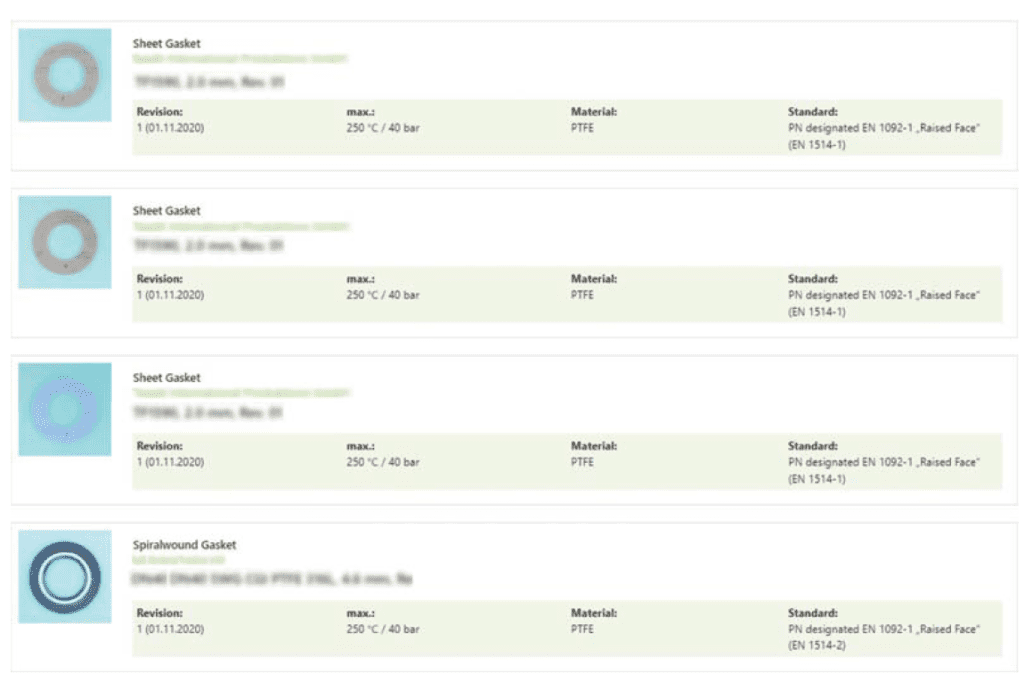

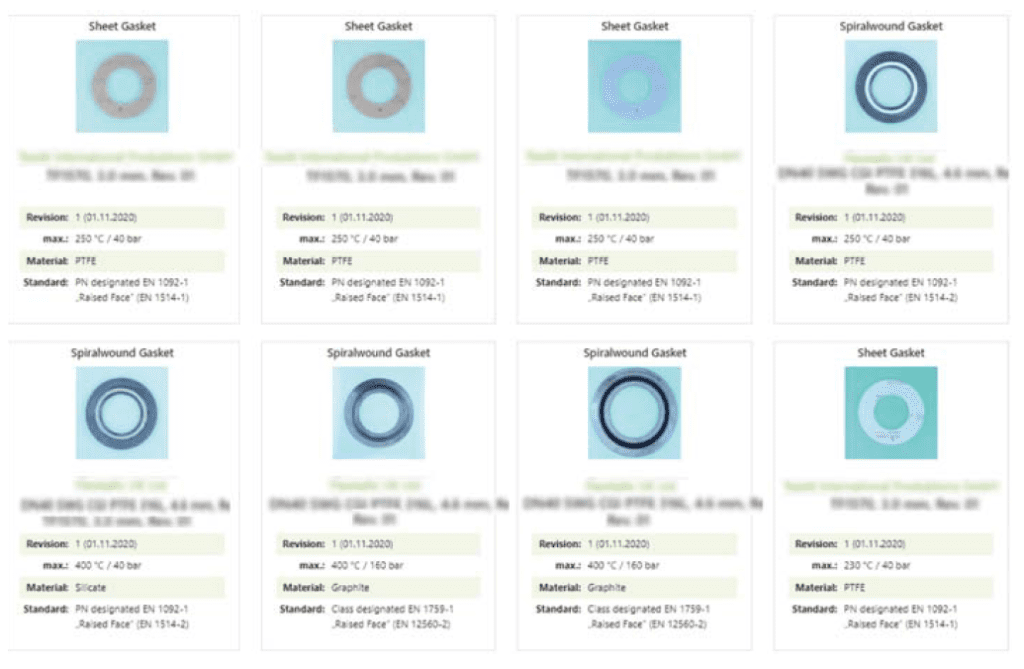

All gaskets that meet these preselected criteria are listed, either in a list view or in a tile view. This overview then shows the most important information about the relevant gaskets and their characteristic values; see Figures 2 and 3.

More detailed information, including all characteristics according to EN 13555 in tables and diagrams, can be obtained by selecting a gasket; see Figure 4. In this view, the data sheets can also be downloaded as a PDF file and the characteristic values themselves in a XML file. The data sheets contain all important information about the gaskets and all characteristic values depending on the test parameters such as temperature, internal pressure, or simulated stiffness of the flange connection.

All data sheets have a revision status and an issue date, so that a previously downloaded data sheet can be checked at any time to ensure it is up to date. The XML file has a fixed structure so that the data can be easily processed further, and the values can be transferred into a software manufacturer’s database.

The database is growing continuously, and more ESA members are taking the opportunity to publish their gasket characteristics on ESAdata.org. But it is not only the number of data sheets that is constantly increasing, but also characteristic values for other test temperatures or test pressures are added, so that the information for all types of applications in the industry is improved.

Future plans

The ESA has decided to open the ESAdata.org database for non-members as well. Manufacturers who fulfil the specified requirements can submit their data for publication on the ESAdata.org database. Alternatively, they can apply for ESA membership, which offers far more opportunities for manufacturers as they can actively participate in the work of the various divisions of the ESA. Please contact info@euopeansealing.com for further information.

ESAdata.org is a developing database and the first phase of the programme was limited to gasket characteristics according to EN 13555, which are required for flange calculations according to EN 1591-1. In the long run, the aim is that the database will be developed to include additional characteristics e.g., HOBT characteristics, ROTT characteristics, m & y values, etc. The database is to be expanded over the next few years to become one of the most important sources of technical information for both gasket and packing materials.

About the author

Dr.-Ing. Manfred Schaaf is Managing Director of amtec GmbH in Lauffen, Germany. He is a member of several national and European standardisation committees for sealing technology, as well as a member of ESA Flange Gaskets Division.

Dr.-Ing. Manfred Schaaf is Managing Director of amtec GmbH in Lauffen, Germany. He is a member of several national and European standardisation committees for sealing technology, as well as a member of ESA Flange Gaskets Division.